A new method called aerodynamic levitation, which, in layman’s terms, allows for a glass mixture to be infused with extra amounts of an aluminum oxide in a container-less setting, has led to the creation of a material stronger than most metals, and nearly as durable as steel.

Researchers at the University of Tokyo and Japan Synchrotron Radiation Research Institute are the ones behind this new technique; they’ve published a paper describing it in Scientific Reports.

A glass this durable has been a long-sought after goal for material scientists. That’s because of the market’s need for such a material, what with the proliferation of smartphones, tablets, and various other mobile devices in recent years, all of which rely on glass to act as the gatekeeper, if you will, between the user and the device’s hardware. These devices travel with their users many places throughout the day, which results in the glass being subjected to bangs, scratches, and drops on a regular basis. Most of these accidents, or an accumulation of the accidents over time, often result in irreversible damage to the glass itself and in some instances, can render the device unusable.

A more durable, nay, an unbreakable glass material, would be the ideal solution, as it would be something the consumer would not need to get used to, and it would already have various established markets to which it could be applied.

One solution that’s proven promising in the past is adding larger amounts of alumina — an oxide of aluminum — to glass mixture. The reason why alumina is targeted is because it has one of the highest dissociation energies among all the oxides, and research has already proven that by adding it to glass would make it significantly stronger than a material created using a more standard approach.

The problem with this approach is that creating a glass with alumina in it is not easy to produce — often what happens is that as more alumina is added, silicon dioxide crystals develop where the glass mixture meets the surface holding it; this, in turn, makes the end product useless as glass.

The Japanese team’s solution: remove the container from the equation altogether.

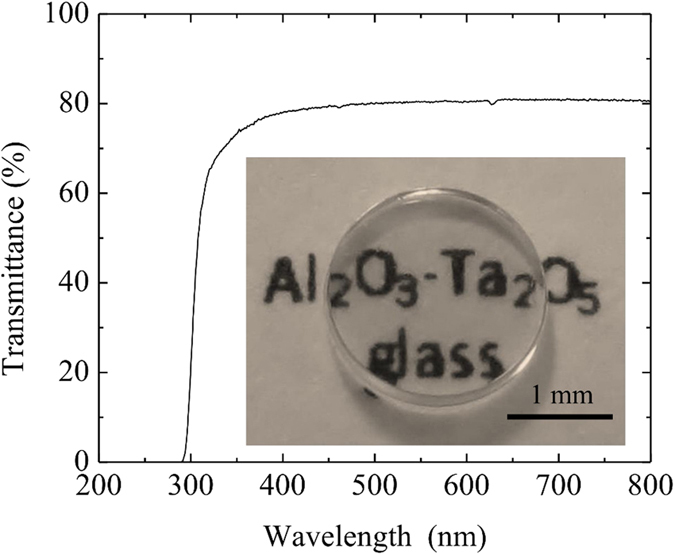

Specifically, the new approach involves having the mixture held in the air while it is forming. This is done by pushing it up from below with oxygen gas, and then using a laser more or less as a spatula to mix everything together. The end result is a transparent, colorless glass material with more alumina in it than anything else that’s ever been produced; this, in turn, makes it harder than any other glass ever produced to date.

In terms of applying this material to devices like smartphones, the team needs to figure out how to convert their method into a mass production process. They believe they have a solution, and hope to have it reported shortly.

To learn more, read their full report, entitled “Glass Fabricated via Containerless Processing”.

Via Phys.org

Advertisement

Learn more about Electronic Products Magazine