The most detrimental factor preventing wearable electronics from really taking off is the delicate balance between form factor and electronics. Until it’s possible to completely obfuscate the underlying electronics without compromising the circuit’s function, wearables won’t ever find their way into commonplace garments. Now, a new manufacturing technique may soon the way for mass-producing flexible electronic circuits by harnessing inkjet printing techniques to apply ultra-thin layers of liquid metal.

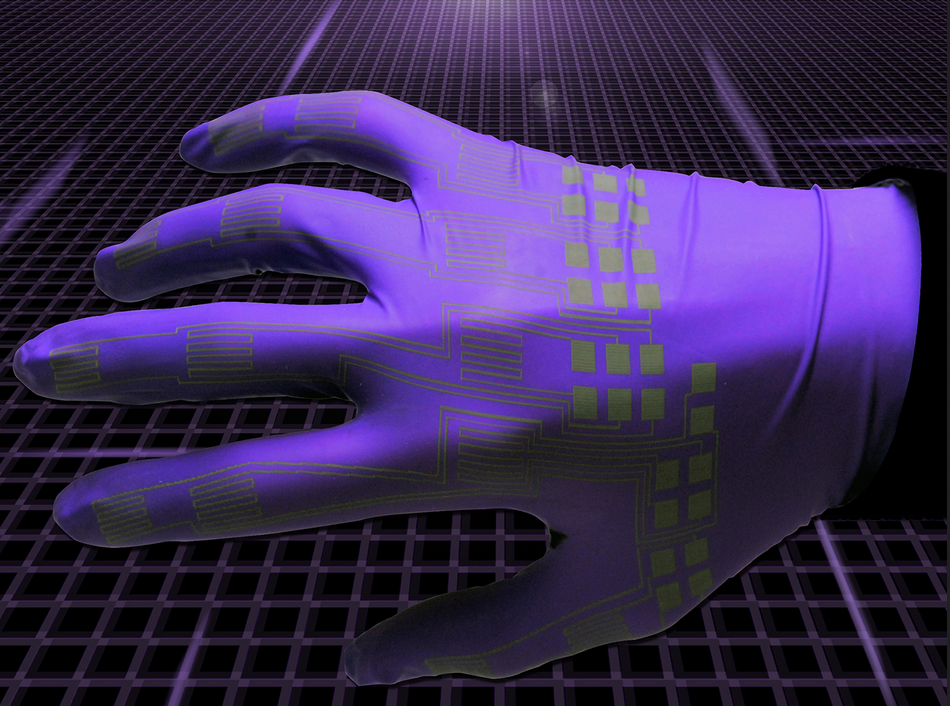

Seeking to develop stretchable electronics that are compatible with both soft robot that squeeze through tight places and wearable technologies that don’t restrict motion, researchers from Purdue University have developed a conductible liquid metal alloy that can stretch and deform without breaking, allowing them to print flexible and stretchable conductors into elastic materials and fabrics.

The printable ink is made from a base of liquid metal gallium-indium placed into a non-metallic solvent such as ethanol, before dispersing it into nanoparticles using ultrasound. Afterwards the ethanol evaporates and the remaining substance is compatible with inkjet printing. The technique, which is called “mechanically sintering gallium-indium nanoparticles,” will be outlined in greater detail in paper appearing in the journal Advanced Materials on April 18.

“Liquid metal in its native form is not inkjet-able,” explains Rebecca Kramer, assistant professor of Mechanical engineering at Purdue, “So what we do is create liquid metal nanoparticles that are small enough to pass through an inkjet nozzle. Sonicating liquid metal in a carrier solvent, such as ethanol, both creates the nanoparticles and disperses them in the solvent. Then we can print the ink onto any substrate. The ethanol evaporates away so we are just left with liquid metal nanoparticles on a surface.”

Once printed on a surface, light pressure must be applied in order to regroup the nanoparticles and remove the initial coat of oxidized gallium, which acts as insulator that prevents conductivity. Kramer exclaims that the process is accomplished by either stamping or dragging a sharp edge, such as that of a silicon tip, across the surface. By selectively activating the conductivity, it’s then possible mass produce a uniform film that may later tailored for each specific function.

The scientists’ next step is to determine the impact that different materials will have on the ink’s conductivity, and if their variance may be used to create other types of circuits.

Source: Phys.org

Advertisement

Learn more about Electronic Products Magazine