By Jean-Jacques DeLisle, contributing writer

Semiconductor producer LG Innotek announced the creation of a new type of thermoelectric semiconductor that utilizes nano-polycrystalline materials. The advancement was announced on June 20 at the Thermoelectric Semiconductor Tech Forum and promises several new cutting-edge advancements. Thermoelectric semiconductors are materials that can produce an electric charge by utilizing a process known as the Seebeck effect, an occurrence wherein a current is created by the temperature differential between different parts of materials. Inversely, when an electric current is passed through a thermoelectric semiconductor, the “Pelter Effect” causes one side of the material to heat and the other to become cold. By taking advantage of the two effects, the new materials are able to produce heating and cooling as well as provide valuable energy by collecting heat that would otherwise be wasted.

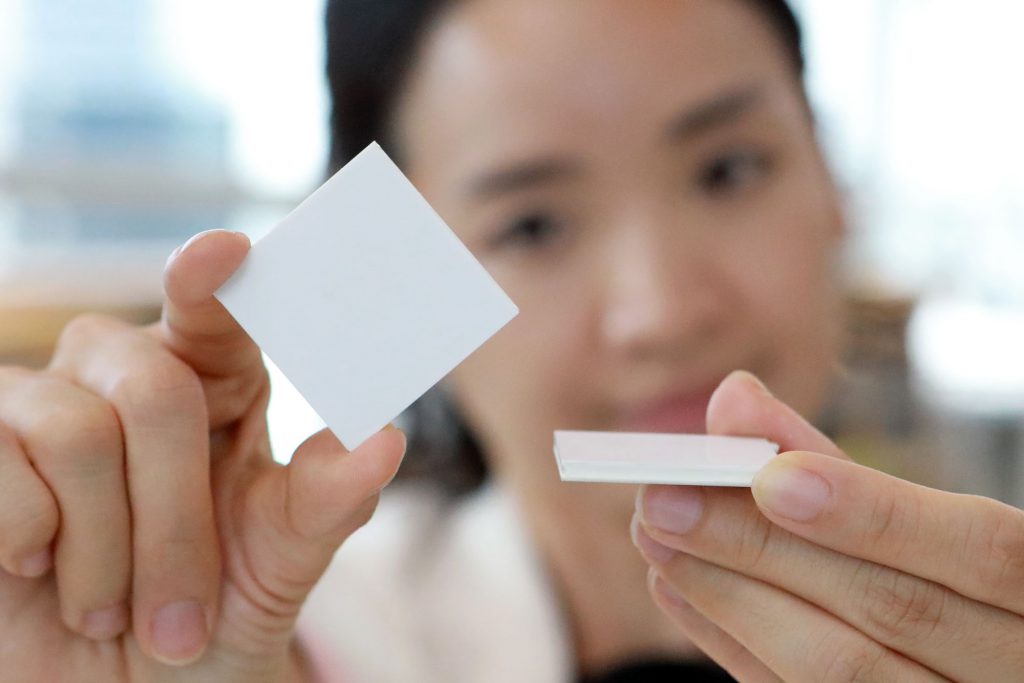

The new LG Innotek nano-polycrystalline design is groundbreaking in many ways. By sizing down the crystalline materials used to create thermoelectric semiconductors to a nanoscale, LG Innotek has managed to increase the durability of these materials by two-and-a-half-fold. The drastic increase in strength provided by these new materials opens up a whole new world of applications for this technology that would have otherwise been impossible for single crystalline materials due to their fragility. Possible new applications for this technology include upgrades to the automotive and boat industry wherein the semiconductors can utilize heat to produce a current, therefore lowering fuel consumption and increasing efficiency.

Image source: LG Innotek.

Older thermoelectric materials were unable to be used for automotive or boat applications because vibrations from large engines would destroy or otherwise render them unusable. The credit to the increase in strength that we see in these new semiconductors is due to their cutting-edge design. By packing large amounts of microscopic nanocrystals together, rather than using large single-crystalline structures, the materials are more rigid and break-resistant.

The semiconductor also utilizes an independent module structure that provides a minimized heat resistance allowing for a 30% increase in cooling effect from a single crystalline thermoelectric semiconductor module. This improved efficiency has the added bonus of lowering power consumption by up to 30%, opening many doors for new applications in low-power cooling.

The communications industry is also eyeing the new thermoelectric materials as a solution to many problems. Optic communications technology must be kept cool and at a stable temperature in order to function properly and keeping them at the perfect temperature requires a lot of power. The increased efficiency of the new semiconductors could solve this problem. Also, access heat from other communications components could be harvested and converted into electricity to be used to cool optical devices.

LG Innotek’s new semiconductors have far-reaching applications and could exceed their non-polycrystalline counterparts in many ways. Another advancement offered by these semiconductors is a reduction in sound. The new thermoelectric materials can provide a powerful cooling effect without the loud sounds that are associated with compression cooling devices such as those found in refrigerators. The new technology is also much smaller and more compact than compression coolers and could lead to much smaller and sleeker refrigeration technology.

TechNavio, a company specializing in tech market research has estimated that the market for thermoelectric semiconductors is expected to grow to US$626.73 million in 2020, a huge leap from last year’s US$471.55 million. In order to keep up with this expected rise in demand, LG Innotek plans to ramp up production of the materials to an unprecedented level in the coming months. According to a company spokesperson, “LG Innotek is now capable of providing a total solution that encompasses R&D, production, and quality management of the thermoelectric semiconductor element modules.”

It won’t be long until we see these thermoelectric polycrystalline semiconductors making their way into everyday technology that we have all around us. The semiconductors have both civil and industrial applications that cannot be ignored. With the high conversion efficiency, they offer heat from existing technology that could be harvested on a larger scale and converted into electricity to power our daily lives. The heat produced by engines is a waste product and shows a lack of efficiency, but the new semiconductors could utilize this energy that would otherwise be lost and convert it into usable viable power, store it in batteries, or use it to power other devices. The applications of these new thermoelectric semiconductors are wide-ranging, and we can only imagine how they will be utilized in the future.

As the world of technology continues to advance, driven by the human desire to create new things and improve the world around us, we will see many new advancements like this in the coming years. Following this trend, we can expect to see smaller, more efficient power technology coming every year for decades to come, and these new semiconductors are just the tip of the iceberg.

Advertisement

Learn more about Electronic Products Magazine