By Warren Miller, contributing writer

As intricate and complex as electronic systems have become in the digital world, they still rely on some of the same essential building blocks as they have since the days of transistor radios. One of those building blocks is the electronic switch — a device that diverts electrical current from one conductor to another. While at first blush, it may seem as if there might not be much room for innovation regarding such a basic component, Menlo Micro and Corning Inc. have collaborated to develop a new benchmark in digital micro-switch technology.

By integrating through-glass-via (TGV) packaging technology, Menlo can reduce the size of its high-performance RF and power products by more than 60% compared to standard available wire-bond packaging technology. This TGV packaging method makes the Menlo/Corning Digital-Micro-Switch (DMS) especially apt for applications requiring reduced size and weight and/or increased channel density.

Replacing traditional wire bonds with metallized vias enables support for the higher frequencies becoming increasingly more necessary in wireless communication systems as well as a multitude of military and aerospace applications. The properties of glass (as opposed to more typical materials like silicon) result in higher overall efficiency while simultaneously reducing energy consumption. In addition, by replacing wire bonds with metallized vias, Menlo reduced package parasitics by more than 75%, supporting increasingly higher frequencies.

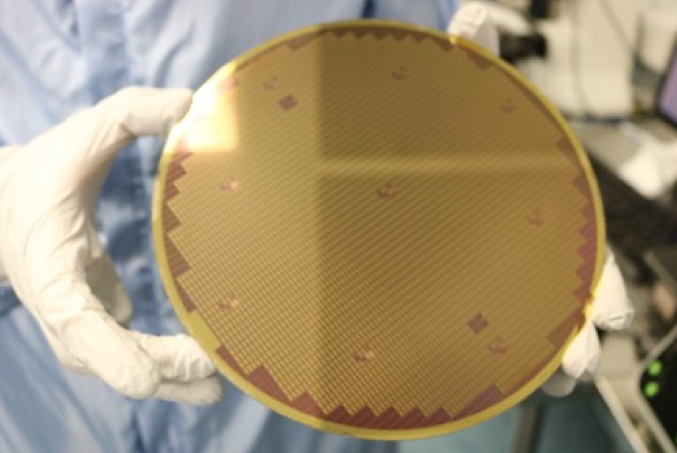

Menlo Micro’s 8-inch RF MEMS wafer with wafer-level-bonded TGV Cap Wafer from Corning. Image source: Menlo Micro.

“The initial decision we made to develop our DMS technology as a metal-to-metal contact switch on a glass substrate was critical to ensure performance,” said Chris Keimel, CTO at Menlo Micro, in a press release.

“Our switch is extremely broadband — able to operate from DC to beyond 50 GHz — but packaging has always been a limitation. By moving to TGV, we have eliminated the unnecessary interconnects that had been limiting performance. More importantly, as our partner and investor, Corning delivered a high-performance via in glass, and our hermeticity and reliability requirements are also achieved. This will allow us to push our product roadmap into new markets. We are substantially increasing performance and reducing overall size and cost to levels that will be truly transformative to many applications.”

The push to performance levels at and beyond 50 GHz could open several new applications areas. Satellites for Earth exploration, radio navigation, inter-satellite communications, and mobile communication are just a few of the possibilities. Back on Earth, 50 GHz also opens up applications for automotive radar, one of the key technologies in the autonomous vehicle sector.

Advertisement

Learn more about Electronic Products Magazine