This post sponsored by Texas Instruments.

As technologies merge, so too do engineering disciplines. Oftentimes, a product or design requires a team that may include hardware, software, power, material, mechanical, optical, chemical, compliance, quality assurance (QA) and supply chain engineers, just to name a few. The products being designed are becoming more complex and precise, which means that the underlying technology to drive and sense needs to become more precise as well.

Take the primed and ready-to-explode 3-D printing market. As more companies offer their versions of 3-D printers, it may appear that the printers that run smoothest, fastest and with the least vibration have an advantage. One major design challenge is to preserve resolution while maintaining speed. But, if they can’t compete with the finer resolutions and capabilities of their noisier competitors, they will lose out. At the end of the day, precision and resolution will win because these features allow the fabrication of parts and sub-assemblies that less-precise machines are just not able to compete with.

Similarly, the medical device industry – and in particular those devices that control medication flow and rate – needs continuous improvement and increasing resolution. In this case, motion sensing is inertia, shock, or other movements that can affect flow rate and can be done using back electromotive force (EMF). Insulin pumps that react to real-time blood-sugar levels, for example, must precisely meter the insulin. Otherwise, a biological oscillation can occur where over-compensation leads to under-compensation on a periodic basis.

Remote vehicles (such as drones and UAVs) are also relying on ever-increasing levels of motor control with real-time sensing to perform stabilization. In such instances, low power and precise control are coupled with real-time processing to allow aerial maneuvers and stabilization for cameras or weapons. Real-time “interference” events such as gusts of wind and drops of rain affect location and orientation, so the more precisely and more rapidly one can measure and react, the more stable the drone platform. Here too, sensing dynamic load as a form of position sensing can be done using back EMF.

These examples rely on motion control and position feedback, both of which are constantly evolving. Forward-looking designers who find and leverage new technologies to increase the effectiveness of their designs will have a distinct advantage, and inductive sensing data converters are one of these new technologies to consider.

Inductance-to-Digital Converters (LDCs)

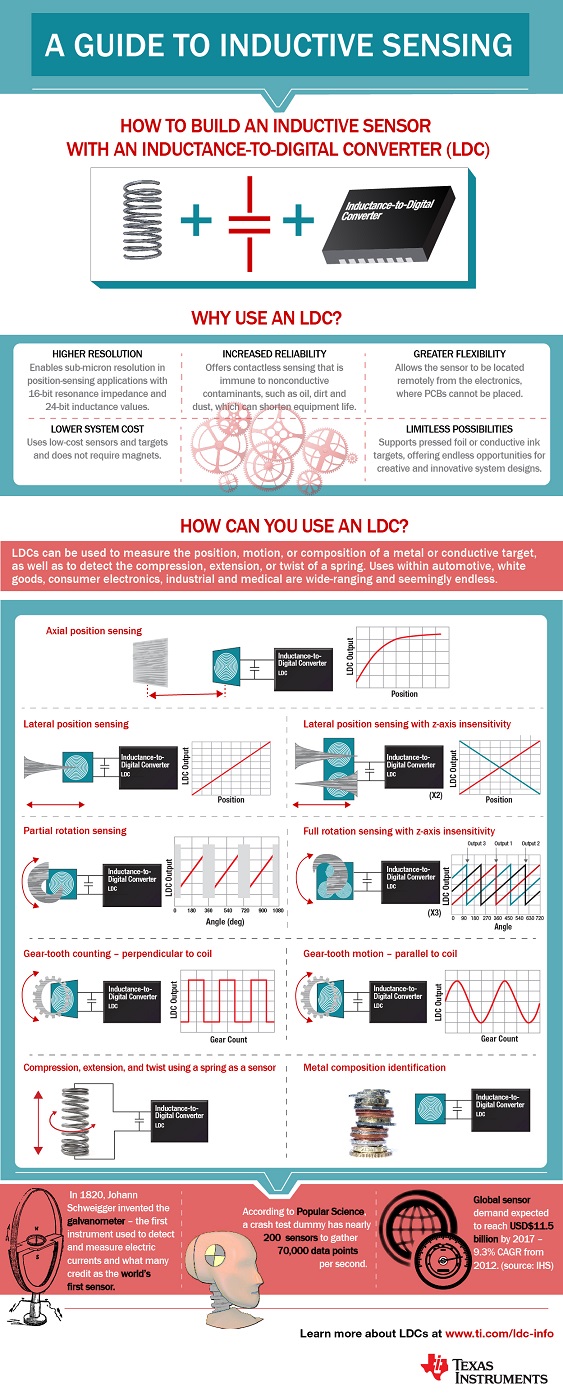

LDCs are oscillating magnetic fields that use parallel resonant impedances to detect the presence of metallic or conductive materials. An LC circuit is used as a tank sensor, and the oscillation frequency becomes a measure of inductance. Sub-micron resolutions are achievable for more precise position sensing and the low-cost solution does not depend on the need for magnets. This can provide better timing control for an engine as an example.

What’s more, the outputs are easily decoded using standard analog-to-digital (A/D) converters and processing software (Figure 1). For example, lateral one-dimensional sensing is linear in response while rotating detection yields angular results directly.

Devices such as the Texas Instruments (TI) LDC1312 and LDC1314 are single-chip two-channel and four-channel (respectively) 12-bit resolution inductance-to-digital converters with I2C connectivity for easy interfacing with virtually any microcontroller. Up to 28-bit values are available with devices like the two- and four-channel LDC1612 and LDC1614 inductance-to-digital converters. For designing with LDCs, the WEBENCH® Inductive Sensing Designer tool helps designers target the dimensions and characteristics of inductors.

Figure 1: Inductive sensing can sense proximity, distance and movement in parallel, perpendicular or rotationally without the need for expensive rare-earth magnets. (Source: Texas Instruments)

Another useful method for position-detection technology is using Hall-effect sensors. Hall sensors are magnetic sensors that are mainly used for position/proximity sensing, but can also be used for speed and direction sensing, rotation sensing, brushless dc motor commutation and rough current sensing. Some devices include TI’s DRV5033 which is an omnipolar switch that responds to both magnetic polarities. And the DRV5053 is a linear Hall-effect sensor for bipolar sensing.

These devices have a wide operating voltage range from 2.5V to 38V, support 40V load dump and -22V reverse battery, and have high magnetic stability over temperature. TI offers both digital and analog Hall sensors for industrial and automotive applications.

As with any new technology, there comes the need to learn and understand it before it can be applied. Fortunately, TI provides several information and application outlets including its complete sensing portfolio. Several helpful blogs that TI also provides include Inductive Linear Position Sensing and How to Design with Inductive Sensors.

Note, TI also helps designers jump-start sensing designs with TI Designs reference designs like the Capacitive-Based Human Proximity Detection for System Wake-Up & Interrupt Reference Design, which uses the FDC1004 for capacitive sensing. In addition, metallic plate-style buttons with haptic feedback can be implemented with LDCs as shown in the TIDA-00314 reference design.

LDC1312

For more information about this product, click here.

To request a sample, click here.

To buy now at Mouser, click here.

To buy now at Mouser, click here.

LDC1314

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

LDC1612

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

LDC1614

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

FDC1004

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

DRV5053

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

DRV5033

For more information about this product, click here.

To request a sample, click here.  To buy now at Mouser, click here.

To buy now at Mouser, click here.

Author: Jon Gabay

Advertisement

Learn more about Texas Instruments