New research is being conducted on how to harvest energy from the sun by a team of scientists at the University of California Santa Barbara (UCSB) Department of Chemistry, Chemical Engineering, and Materials. The team was able to convert sunlight into energy by using a process based on metals that are more robust than many of the semiconductors used in traditional methods.

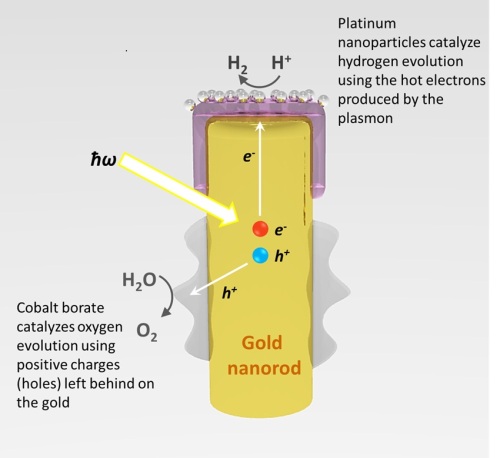

The process by which light is captured by the gold nanorod, and converted into energy that can spilt water (H2O) into hydrogen and oxygen.Credit: Syed Mubeen

In the traditional method, the sunlight hits the surface of semiconductor material, one side of which has many electrons, while the other not so many. The light particles excite the electrons, causing them to leave their positions, and create positively charged “holes.” This current of charged partilces can be captured and delivered for various uses, including powering lightbulbs, energizing batteries, or participating in chemical reactions.

in the new process, the UCSB team used nanostructured metals (specifically, gold nanorods) instead of semiconductor material. The gold nanorods were capped with a layer of crystalline titanium dioxide decorated with platinum nanoparticles, and set in water. A cobalt-based oxidation catalyst was deposited on the lower portion of the array. “When nanostructures, such as nanorods, of certain metals are exposed to visible light, the conduction electrons of the metal can be caused to oscillate collectively, absorbing a great deal of the light,” said Moskovits, professor of chemistry at UCSB. “This excitation is called a surface plasmon.”

Specifically when the “hot” electrons are excited by light particles, they move up the nanorod and captured by platinum particles. The hydrogen ions split up from the bond that forms water, while the holes left behind by the excited electrons move to the cobalt-based catalyst, which is in the lower part of the rod to form oxygen. It was recorded that hydrogen production took about 2 hours. Here the nanorods were not subject to photocorrosion that causes traditional semiconductor material to fail in minutes. The downfall is that this method of splitting water is less efficient and more costly than traditional photoprocesses, but the team believes that continued research will improve of efficiency and cost of this method.

The team also consisted of postdoctoral researchers Syed Mubeen and Joun Lee, grad student Nirala Singh, materials engineer Stephan Kraemer, and chemistry professor Galen Stucky. The complete research was published in the latest issue of the journal Nature Nanotechnology . For more information, contact Sonia Fernandez at 805-637-3726 or George Foulsham at 805-893-3071.

Advertisement

Learn more about Electronic Products Magazine