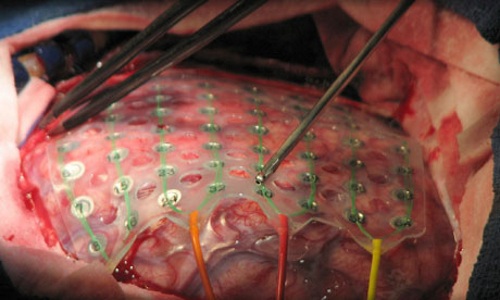

At present, one form of treating those suffering from severe epilepsy is to drill through the individual’s skull, deep into the brain, in order to destroy the small area where seizures originate.

The procedure is obviously invasive. It’s also dangerous and comes with a long recovery period. In order to find a better way of performing this procedure, engineers at Vanderbilt University set out to develop technology that would allow doctors to treat epileptic seizures in a less invasive way.

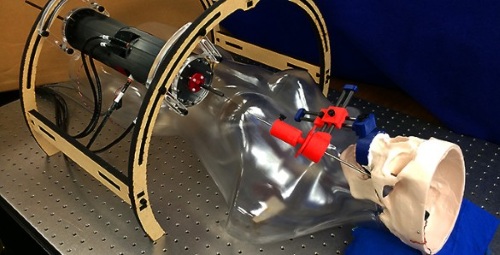

The result of their efforts is a robotic device that pokes through the cheek and enters the brain from underneath, much closer to the target areas. This, in turn, allows surgeons to altogether avoid drilling through the skull.

At the end of the device is a 1.14-mm nickel-titanium needle that acts like a mechanical pencil, with concentric tubes (some of which are curved), that allow the tip to follow a curved path to the brain. Combined with compressed air, a robotic platform steers and advances the needle segments a millimeter at a time.

Two things to note: nickel-titanium was chosen as the material source due to the fact that it is compatible with MRI machines. Also, the use of a robotic platform gives the doctor the additional benefit of greater control. This means that as the needle is inserted in tiny, measured steps, the surgeon can track its position by taking successive MRI scans.

David Comber, the graduate student in mechanical engineering who did a bulk of the design work, said that the group measured the accuracy of the system and found it is better than 1.18 mm, which is considered sufficient for this type of operation.

As per associate professor of mechanical engineering Eric Barth, who headed the project, the next stage for the surgical robot is to test it out on cadavers. He estimates it could be in operating rooms within the next 10 years.

Barth explained that to come up with the design, the team first started with the capabilities they already had.

“I've done a lot of work in my career on the control of pneumatic systems,” Barth said. “We knew we had this ability to have a robot in the MRI scanner, doing something in a way that other robots could not. Then we thought, 'What can we do that would have the highest impact?'”

While this research was taking place, associate professor of mechanical engineering Robert Webster developed a system of steerable surgical needles. “The idea for this came about when Eric and I were talking in the hallway one day and we figured that his expertise in pneumatics was perfect for the MRI environment and could be combined with the steerable needles I'd been working on,” he explained.

The engineers next identified epilepsy surgery as an ideal, high-impact application following discussions the two had with associate professor of neurological surgery Joseph Neimat. It was during these talks that Barth and Webster learned current neuroscientists use a through-the-cheek approach to implant electrodes in the brain to track brain activity and identify where epileptic seizures originate. The problem they were running into in terms of surgery was that the straight needles couldn’t reach the hippocampus, the source region. So instead, the surgeons had to drill through the skull and insert the needle to destroy misbehaving neurons.

Comber and Barth shadowed Neimat through a series of brain surgeries to understand how their device would function in the operating room.

“The systems we have now that let us introduce probes into the brain — they deal with straight lines and are only manually guided,” Neimat said. “To have a system with a curved needle and unlimited access would make surgeries minimally invasive. We could do a dramatic surgery with nothing more than a needle stick to the cheek.”

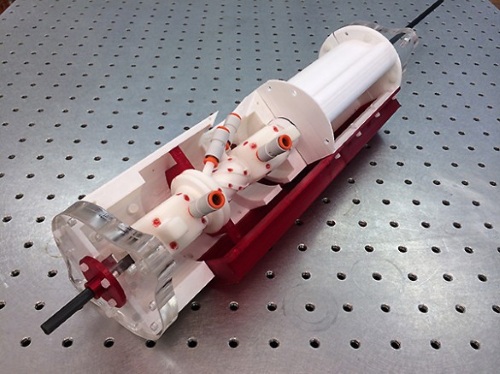

The device the engineers wound up developing was designed in such a way that it can be made using 3D-printing techniques. This was done on purpose so that it will keep the price low. The engineers received assistance on this end of the project from the Milwaukee School of Engineering, which specializes in novel applications for additive manufacturing.

Cutaway shows how much of robotic device can be made via 3D printing.

Via Vanderbilt.edu

Advertisement

Learn more about Electronic Products Magazine