BY CHAD HALL, Co-founder and VP of Marketing and product management, Ioxus, www.ioxus.com

Engineers are constantly exploring new ways to improve functionality, maximize performance and keep abreast of technological advances that will enable them to build better products than competitors. An area engineers have started investigating as part of their research into the next generation of energy is how to make batteries more efficient and better-performing. This research is leading them to see the benefits of using ultracapacitors to achieve enormous bursts of energy and provide a more reliable end-product for the consumer.

An ultracapacitor stores energy in an electric field, as opposed to batteries which store energy chemically. This means that ultracapacitors can complete hundreds of thousands more charge and discharge cycles than batteries because they do not experience the standard wear and tear associated with chemical reactions. Research shows that over the energy storage systems’ (ESS) lifespan, ultracapacitors are the most cost-effective technology (see Fig. 1 ) and last 15 years, compared to two to four years with a lead acid battery. An ultracapacitor located at the point of demand offers engineers an opportunity to simplify the design process as a whole, without sacrificing performance.

Fig. 1: Initial System Cost Over Time: The predicted cost of the ultracapacitor-based system is less than the cost of the current best solution, which is double absorbed glass mat (2xAGM) batteries, and is only about 20 percent more expensive than the traditional dual starting-lighting-ignition (2xSLI) solution.

Lack of capacitor education

However, therein lies the problem. Unfortunately the explanation above isn’t much shorter than what engineers are used to, as they spend roughly 30 to 60 minutes learning about ultracapacitors while in college. This lack of education into the functionality, uses, and benefits of ultracapacitor technology has created several misconceptions that are limiting the progression of ESS and the applications it serves. Though the shift away from sole battery use is taking place, a change in mindset is still needed from an engineering standpoint.

Most people consider the battery the last stop in energy storage. Batteries are efficient and they can provide stored energy reliably, but its limitations and inability to adapt to increased expectations make it a less than ideal technology for today’s applications. Batteries struggle under moments of high peak power and do a poor job of delivering the frequent, short power boosts many applications require, such as transportation and memory backup.

The number one misconception of ultracapacitors is that they’re trying to replace batteries – this is incorrect. They enhance the battery, make it last longer, and reduce warranty issues related to replacing batteries.

Applications still require a battery to provide the consistent, low energy for long periods of time, while the ultracapacitor handles all of the high current work due to its low resistance. This hybrid energy storage system of pairing ultracapacitors with batteries, results in a reduced battery size. The ultracapacitor provides power, which means engineers and manufacturers can size the battery for the energy requirements needed, and use a smaller, high energy density battery. Using a hybridized storage system allows for the strengths and weaknesses of each technology to balance each other out, providing an overall improved system. Studies have demonstrated that a simple parallel connection of an ultracapacitor to even a low-cost alkaline battery can duplicate the performance characteristics of a lithium-ion battery. For example, the power needed for acceleration in an electric car can come from an ultracapacitor, while a battery provides range and recharges the ultracapacitor between surges.

How capacitors charge

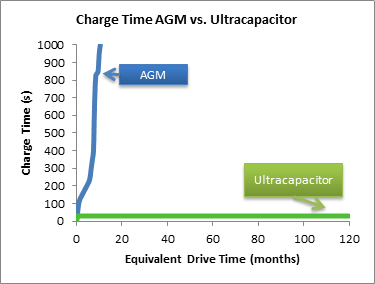

An important piece of information is for engineers to understand how ultracapacitors charge (see Fig. 2 ). They follow strict current-based charging rules, where the cell absorbs as much current as is supplied to it, while its voltage increase is based on how much charge it has accumulated. Care must be taken in designs for charging ultracapacitors at a low state of charge, since they will act like a short circuit when their voltage is near zero. Hybridized storage systems can be recharged as quickly as they can be discharged, allowing for a rapid charge to support a high power demand.

Fig. 2: Example of charge time of ultracapacitor vs. absorbed glass mat (AGM) battery. For simplicity, the ultracapacitor charge time is shown as constant (regulated); this should be considered a minimum value. Ultracapacitor charge time only is limited by the ability of the alternator to generate current in a start/stop system.

Environmental responsibility is a term used to describe ‘being green’, and engineers and designers are in a unique position to make a positive impact. Ultracapacitors have no detrimental effects on the environment and are built to provide cost-effective, green energy solutions. This is a component many buyers expect in today’s products. Consider the auto industry and how this helps engineers meet the significant challenges presented by the corporate average fuel economy (CAFE) regulations, which calls for automakers to lower vehicle emissions and improve fuel efficiency. Ultracapacitors have the ability to produce hybrids with 10 to 20 percent better fuel efficiency. There are also new taxes and incentives set in place to encourage consumers and manufacturers to purchase and provide automobiles that offer higher fuel efficiency. Additionally, the weight of an ultracapacitor is only a fifth of a comparable battery, which in turn allows for better fuel consumption and happier consumers as running costs are lowered.

Energy storage future

The future of energy storage design lies with engineers who embrace advances in technology and look towards power beyond the battery. They must produce products that are more efficient, more reliable, are cost-effective to operate, and at the same time incorporate features that make them more desirable than competing products. We’re on the verge of a rebirth of our global energy storage systems, which will play an increasingly important role as the world moves forward into a clean energy future. This transition must include improved batteries and high-energy density ultracapacitors because the technology offers far better ROI than any other energy storage medium, and the best performance and the highest safety ratings of any ESS available on the market today.

Advertisement

Learn more about Ioxus