By Alex Pluemer, contributing writer

Oxis Energy U.K. Ltd. is working with 12 other European partners to launch the Lithium Sulfur for Safe Road Electrification (LISA) project in January 2019, a collaboration to advance lithium-sulfur (Li-S) battery technology that will enable the safe electrification of electric vehicle (EV) applications. The 43-month project will receive approximately $9 million in funding from the European Union’s Horizon 2020 research and innovation program.

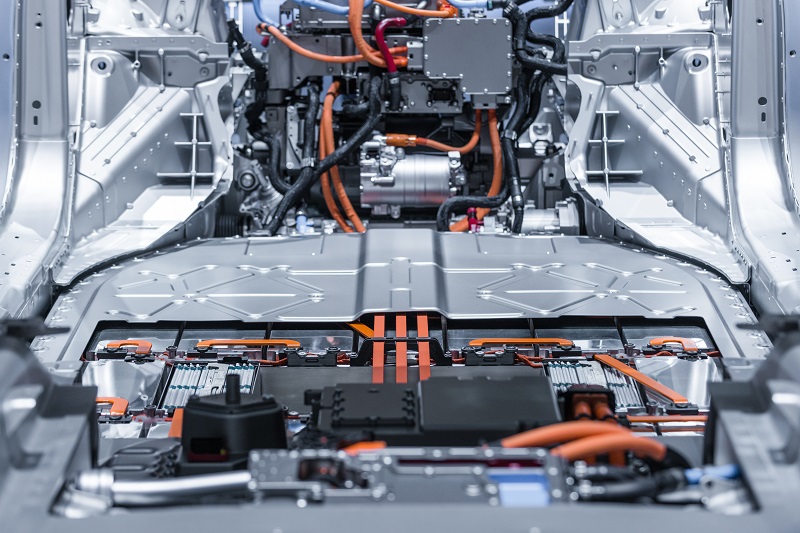

Lithium-ion (Li-ion) batteries are currently the limiting factor in the large-scale adoption of EVs and hybrid vehicles. The next generation of EV battery technology will need to provide a greater driving range, faster charging at a lower cost, and better safety, said Oxis.

Li-S technology is an emerging alternative to Li-ion batteries. The technology doesn’t use any critical raw materials such as natural graphite and cobalt and it isn’t limited in capacity and energy by intercalation materials.

Image: Shutterstock

LISA will focus on the development of high-energy Li-S battery cells with hybrid solid-state non-flammable electrolytes validated at a 20-Ah cell level to help solve the common problems that are holding back Li-S development, including metallic lithium protection, power rate, and volumetric energy density, said Oxis. The group will also focus on cost, which is the primary criteria for EV batteries, and other factors such as environmental impact that play a key role in the sustainability of the Li-S technology.

Currently, Li-S is twice as light as Li-ion and has reached only 10% (250–300 Wh/kg) of the theoretical energy density of 2,600 Wh/kg at the cell prototype level. LISA believes that number could double to approximately 600 Wh/kg by improving materials, components, and manufacturing.

The project is committed to the development of lithium-metal protection and solid-state electrolytes and plans on incorporating process concepts to enable integration into future manufacturing lines, said Oxis. Any new materials, components, cells, and/or processes that the project implements will be transferrable to other lithium-anode–based technologies, including Li-ion.

Members of the LISA consortium, led by LEITAT, a Technological Institute recognized by the Catalan Government (TECNIO) and the Spanish Ministry of Science and Innovation, includes Oxis, Cranfield University, Varta Micro Battery GmbH, CIC Energigune, ARKEMA, Fraunhofer Gesellschaft Zur Förderung De Angewandten Forschung, Pulsedeon Oy, ACCUREC Recycling GmbH, Optimat Ltd, Technische Universität Dresden, VDL Enabling Transport Solutions BV, and Renault.

More information on the advantages of Li-S technology can be found here.

Advertisement

Learn more about Electronic Products Magazine