By LOUIS ADAMS,

Southwest Regional Manager

Tadiran Batteries

tadiranbat.com

As self-powered medical devices become increasingly sophisticated and miniaturized, the choice of power supply becomes more critical for applications ranging from surgical drills and medical power tools to automatic external defibrillators (AEDs), infusion pumps, bone growth stimulators and other wearable devices, glucose monitors, blood oxygen meters, cauterizers, RFID asset tracking tags, and other remote wireless devices.

Self-powered medical devices increasingly require the use of industrial grade primary lithium batteries instead of consumer grade batteries for various reasons, including:

- Reliability – patient wellness depends on procedure outcome

- High power-to-size ratio – enables the medical device to be smaller, lighter, and more accurate

- Small physical size – allows the device to be ergonomically designed for comfort and ease-of-use

- Long shelf life – ensuring that the device will operate reliably after long storage periods without needing to recharge or replace the battery

- High temperature survivability – if sterilization is required

- Cold temperature operability – for items transported through the cold chain

- Ability to supply high pulses –to run motors and communications circuits.

A choice among primary lithium chemistries

Primary lithium batteries deliver the highest specific energy (energy per unit weight) and energy density (energy per unit volume) of any battery chemistry, with a non-aqueous electrolyte, and a nominal open circuit voltage of 1.7 to 3.9V. Table A summarizes the the various chemistries that are available.

Table A: Primary lithium battery characteristics

Lithium manganese dioxide (LiMNO2 ) cells power hand-held devices such as glucose monitors, but suffer from a narrow temperature range and a high annual self-discharge rate.

Lithium sulfur dioxide (LiSO2 ) batteries deliver high pulses, especially at low temperatures, but add bulk due to their low energy density, and have a high annual self-discharge rate.

Bobbin-type lithium thionyl chloride (LiSOCL2 ) cells feature very high energy density and high capacity, along with a very low annual self-discharge rate, enabling low power devices to operate for up to 40 years. These cells feature a wide temperature range (-80o C to 125o C), making them ideal for autoclave sterilization and for use in the medical cold chain.

Due to their low rate design, standard bobbin-type LiSOCL2 batteries cannot deliver high pulses. One solution is to combine a standard bobbin-type LiSOCL2 battery with a patented hybrid layer capacitor (HLC) that stores energy and delivers periodic high pulses. Another option is to combine a standard LiSOCL2 battery with a supercapacitor, which is a bulkier, more complex, and more costly solution.

Specialized batteries deliver high rate current

A lithium metal oxide battery, the TLM Series, was developed for applications requiring continuous high rate power, such as surgical drills and power tools.

Constructed with a carbon-based anode, a multi metal oxide cathode, and an organic electrolyte, TLM Series cells feature a nominal voltage of 4V and up to 2 Wh of energy, with a discharge capacity of 135 mAh to 500 mAh, capable of handling 5A continuous loads and 15A maximum pulses. These powerful little cells offer up to 20-year shelf life due to a low annual self-discharge rate (less than 1% per year), along with a wide temperature range (-40° to 85°C) and a hermetic seal.

Some real-life examples

Bone growth stimulator (low continuous current)

Stimulating bone growth and healing requires low-intensity, high frequency sonic pressure waves. Use of a standard bobbin-type LiSOCL2 battery pack enables this wearable device to be compact and lightweight.

AED (long shelf life, high pulses)

Automatic external defibrillators (AEDs) require extremely long battery shelf life, often remaining idle for extended periods, but then must operate reliably in an emergency. Combining a standard LiSOCL2 battery with an HLC delivers both a low annual self-discharge rate (less than 1% per year) along with pulses of up to 15 A to stimulate a heartbeat.

Hand-held surgical drills (high rate, high pulse)

Pro-Dex automatic torque limiting surgical screwdrivers permit neurosurgeons to insert titanium screws into titanium plates at just the right depth to cover portions of the skull removed during surgery (see Fig. 1), thus eliminating the risk of unsightly bumps or additional patient discomfort.

Fig. 1: A portable, automatic torque limiting surgical screwdriver permits neurosurgeons to insert titanium screws into titanium plates at just the right depth in the skull.

According to Stu Gallant, vice president of product and business development at Pro-Dex, “Creating a truly surgeon-friendly power tool requires the ideal power supply, as selecting the ideal battery can result in a dramatic reduction in size and weight without sacrificing power or performance.”

After reviewing several primary lithium chemistries, Pro-Dex selected TLM Series lithium metal oxide batteries for their ability to deliver high pulse amplitude and up to 4.1 V continuous current per cell during active drilling cycles. Two models are currently available: one that uses two TLM 1550HP batteries to deliver 8 V of variable current for drilling speeds up to 2,200 rpm; and another model that uses four TLM 1550HP batteries to deliver 16 V of variable current for drilling speeds up to 4,000 rpm.

Fig. 2: A surgical drill provides variable speeds to 4,000 rpm with four lithium metal oxide batteries

Pro-Dex surgical screwdrivers are reusable, except for the battery pack. In the future, these devices could be made fully re-usable by using an industrial grade Lithium-ion (Li-ion) battery, the TLI Series, which can deliver up to 15 A of continuous current (AA size cell), able to operate for 20 years and 5,000 full recharge cycles, while offering an extended temperature range and a hermetic seal.

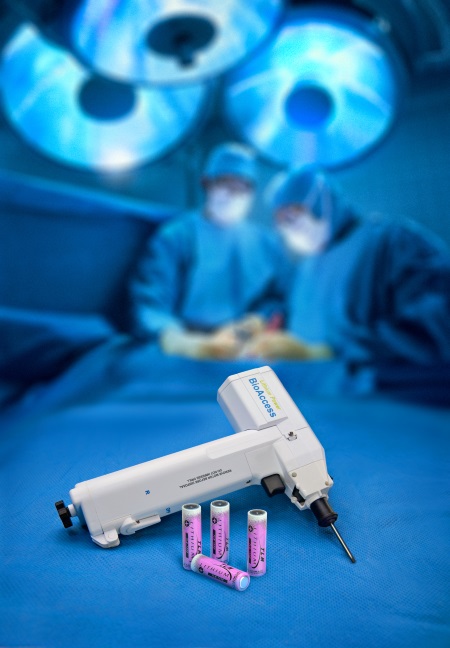

Hand-held surgical drill (a smaller alternative to alkaline batteries)

BioAccess, a surgical device manufacturer, now offers lithium metal oxide batteries as an optional power supply upgrade for a surgical drill that was previously powered by alkaline battery packs. The alkaline batteries performed well and offered excellent reliability, but added unnecessary weight. Use of the optional lithium metal oxide battery pack enables faster drilling speeds, more active drill time (30 to 40 seconds at a time for up to 20 to 30 cycles), more instantaneous power, and greater stall torque for more efficient drilling cycles with less operator fatigue.

Substituting 6 AA-size TLM-1550HP batteries for the alkaline battery pack also enabled BioAccess to achieve a 36% weight reduction with only 40% of the volume. An equivalent alkaline battery pack would have required 3X the weight and 2.5 times the volume (15 AA-size alkaline batteries vs. 6 AA-size TLM-1550-HP batteries).

Recent advancements in lithium battery technology have enabled medical devices to become increasingly miniaturized without sacrificing performance.

Advertisement

Learn more about Tadiran