IIoT-connected devices are becoming truly wireless to monitor hard-to-access and off-the-grid environments. In applications where battery-powered solutions are required, there are two main types of industrial remote wireless devices.

One type draws an average amount of energy (including background current and pulses) measurable in microamps and is typically powered by industrial-grade primary (non-rechargeable) lithium batteries. The other type of application draws an average amount of energy (including background current and pulses) measurable in milliamps and is typically powered by an energy-harvesting device in combination with a lithium-ion (Li-ion) rechargeable battery.

Understanding the various primary (non-rechargeable) batteries

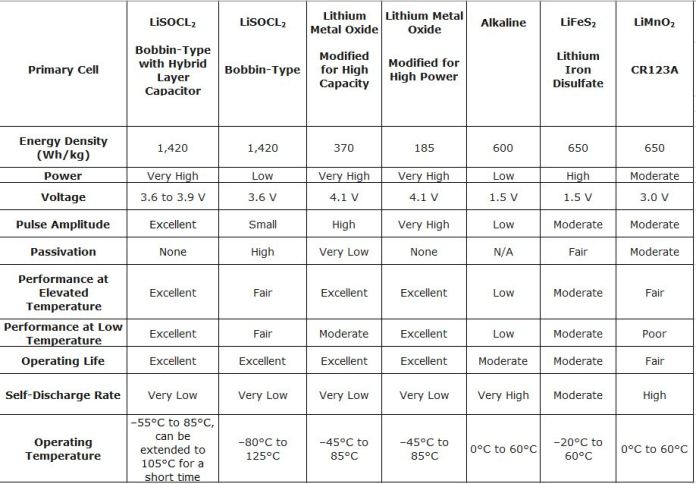

The vast majority of remote wireless devices are powered by primary batteries. Numerous chemistries are available, including iron disulfate (LiFeS2), lithium manganese dioxide (LiMnO2), lithium thionyl chloride (LiSOCl2), and lithium metal oxide (Table 1).

Lithium batteries are preferred for industrial wireless applications due to their high intrinsic negative potential, which exceeds all other metals. As the lightest non-gaseous metal, lithium offers the highest specific energy (energy per unit weight) and energy density (energy per unit volume) of all available battery chemistries. Lithium cells operate within a normal operating current voltage range of 2.7 to 3.6 V. The chemistries are also non-aqueous, thus less likely to freeze in extreme temperatures.

Bobbin-type LiSOCl2 batteries are predominantly chosen for long-term deployments in extreme environments, including AMR/AMI metering, M2M, SCADA, tank-level monitoring, asset tracking, and environmental sensors, to name a few. Bobbin-type LiSOCl2 cells feature the highest capacity and energy density of any chemistry, along with the lowest annual self-discharge rate (under 1% per year for certain cells), enabling up to 40-year battery life. These cells also feature the widest possible temperature range (–80˚C to 125°C), making them ideal for hard-to-access locations and extreme environments.

Understanding battery self-discharge

All batteries experience some amount of self-discharge, which occurs naturally as chemical reactions sap energy even while the cell is disconnected or in storage. Self-discharge is influenced by the cell’s current discharge potential, the purity and quality of the raw materials, and the passivation effect.

Passivation is unique to LiSOCl2 batteries, involving a thin film of lithium chloride (LiCl) that forms on the surface of the lithium anode to limit reactivity. When a load is placed on the cell, the passivation layer causes initial high resistance and a temporary dip in voltage until the discharge reaction begins to dissipate the LiCl layer — a process that repeats itself each time the load is removed.

The passivation effect has several influences, including current capacity, length of storage, storage temperature, discharge temperature, and prior discharge conditions. Removing the load from a partially discharged cell increases the level of passivation relative to when it was new. Passivation extends battery life, but too much of it can overly restrict energy flow.

Other factors influence battery self-discharge, including the cell’s current discharge potential, the method of manufacturing, and the quality of the raw materials. For example, a high-quality bobbin-type LiSOCl2 cell can feature a self-discharge rate as low as 0.7% per year, retaining 70% of its original capacity after 40 years. By contrast, a lower-quality bobbin-type LiSOCl2 cell can experience a self-discharge rate of up to 3% per year, losing 30% of its initial capacity every 10 years, making 40-year battery life impossible.

Adapting to high-pulse applications

A growing number of wireless devices mainly operate in “standby” mode, drawing minimal amounts of current and requiring periodic high pulses to power two-way wireless communications.

Standard bobbin-type LiSOCl2 batteries cannot deliver high pulses due to their low-rate design. This can be overcome by adding a patented hybrid layer capacitor (HLC).

The standard bobbin-type LiSOCl2 cell delivers low daily background current, while the HLC handles periodic high pulses. The patented HLC also features a special end-of-life voltage plateau that can be interpreted to deliver automatic low-battery status alerts.

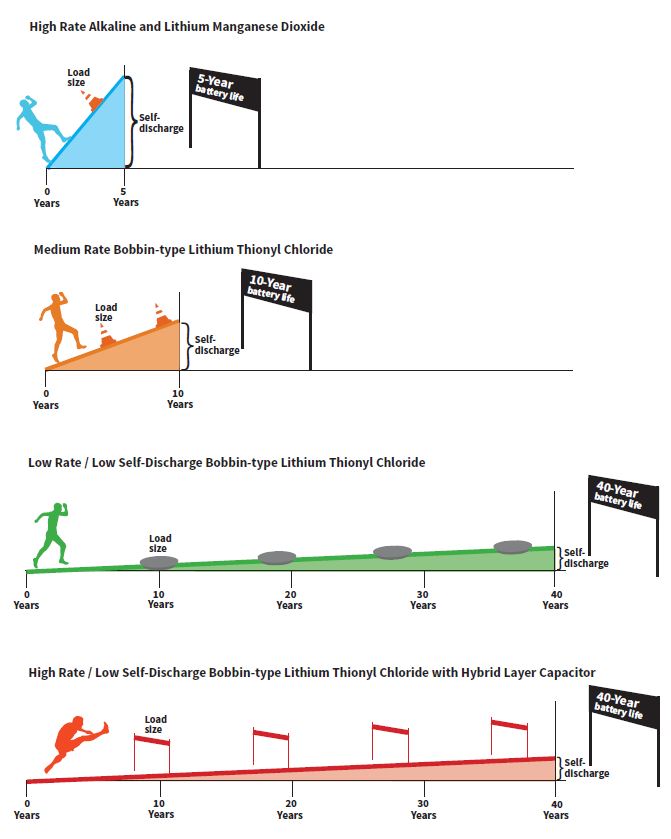

Battery life can be compared to a race

Does your application require speed (higher flow rate) or distance (extended battery life)? This is analogous to sprinting versus long-distance running:

- High-rate cells: Run steeply uphill with a small number of high pulses measurable in amps, resulting in a maximum battery life of up to five years.

- Medium-rate cells: Run with a smaller incline with pulses measurable in hundreds of milliamps, resulting in a maximum battery life of up to 10 years.

- Extra-long–life cells: Run on an almost-flat track with numerous small hurdles/pulses measurable in tens of milliamps, thus creating the potential for 40-year battery life.

- Extra-long–life cells with periodic high-rate pulses: Run on an almost-flat track with a large number of taller hurdles/pulses measurable up to tens of amps, thus creating the potential for 40-year battery life.

Other factors influence the choice of an industrial-grade primary lithium battery, including the amount of current consumed in active mode (along with the size, duration, and frequency of pulses), energy consumed in standby or sleep mode (the base current), storage time (normal self-discharge during storage diminishes capacity), and expected temperatures (during storage and in-field operation). Additional considerations include the equipment cutoff voltage (as battery capacity is exhausted, or in extreme temperatures, voltage can drop to a point too low for the sensor to operate), and the annual self-discharge rate of the battery (which can approach the amount of current drawn from average daily use).

Short-term test results cannot predict a marathon

The long-term impact of a higher self-discharge rate may not become apparent for years, and theoretical methods for predicting actual battery life generally underrepresent the importance of the passivation effect along with long-term exposure to extreme temperatures.

If your application demands long-life power, you must carefully evaluate potential suppliers by requesting fully documented long-term test results along with long-term in-field test data taken from comparable devices under similar loads and environmental conditions. Knowing your battery and your application requirements will help improve the device’s performance and extend battery life to reduce the cost of ownership.

Advertisement

Learn more about Tadiran