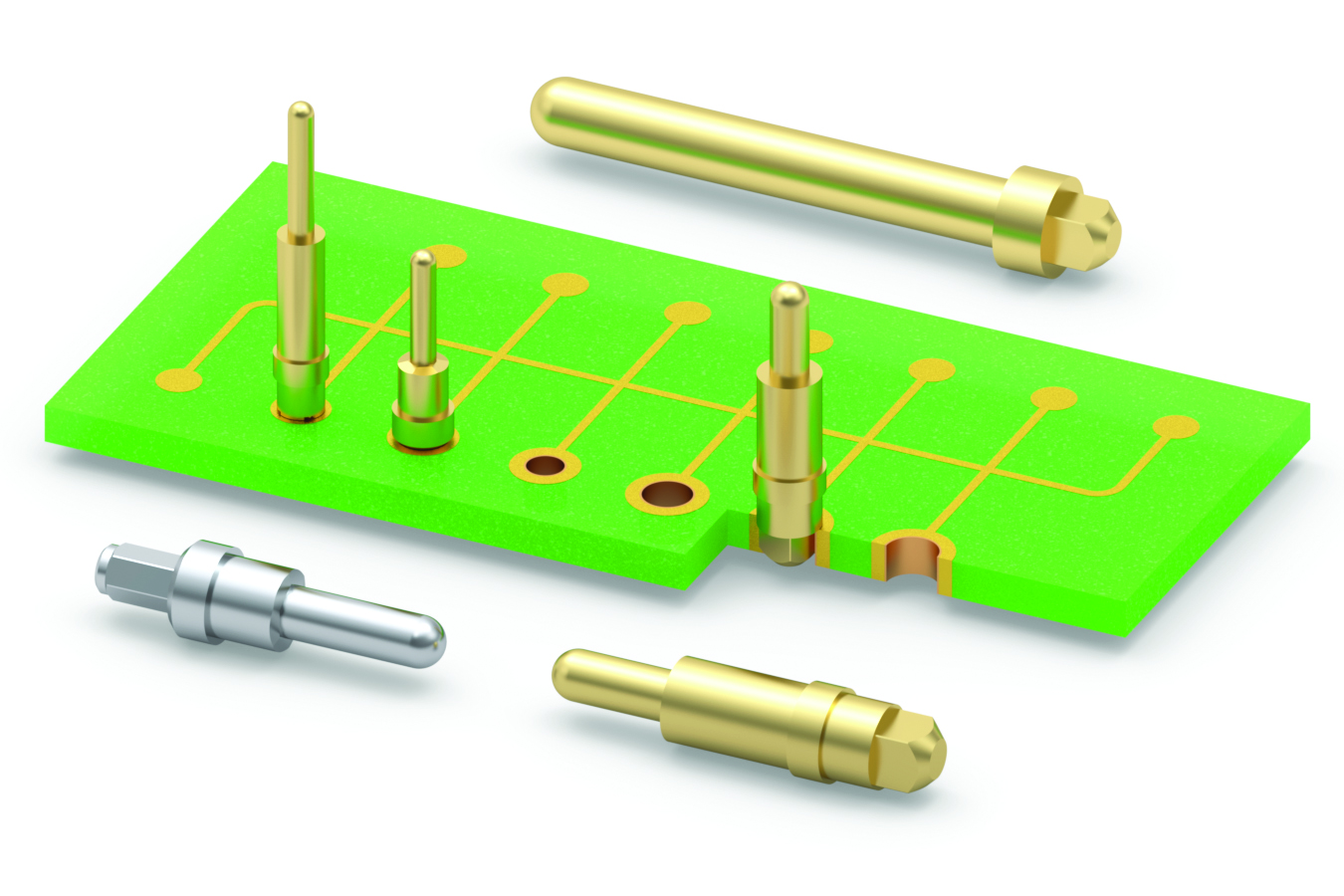

Mill-Max has introduced six new press-fit PCB pins that feature multi-faceted polygon geometries and are especially suitable for solderless PCB termination as well as direct soldering to the board. The smallest pin diameter in the group is 0.040 inches while the largest is 0.080 inches.

These press-fit PCB pins are designed with the electrical and mechanical strength required in applications such as power supplies and power converters. Then there are high-current applications that are otherwise limited by temperature requirements and heat-sinking abilities of the environment.

The devices subject to blind mating or rough handling can also benefit from these PCB pins. The pin material is brass. However, tellurium copper is also available for greater electrical conductivity and more efficient heat dissipation.

You can simply press these pins into a plated through-hole. The polygon points are set in the hole, so the flat sides of the hardware can provide relief. And that allows the remainder of the plated through-hole barrel to remain intact.

As a result, internal board layers are not disconnected when the pin is pressed in. The polygon shaped press-fit allows the pin to be secure in the hole while the hole size is properly specified. That provides continuity across all the layers of the PCB.

Mill-Max can manufacture either square- or hexagon-shaped press-fit PCB pins to suit a variety of hole sizes and assembly requirements. Square press-fit pins usually leave a larger gap between the flat side of the feature and the hole and are useful for solder flow and venting of gasses. On the other hand, hexagon pins provide greater retention.

Advertisement

Learn more about Mill-Max