The human body is a true wonder. It serves as a model for numerous industrial developments. Take membranes, for example: they ensure that every cell in our body remains healthy by being permeable to the good substances that protect the inside of the cell while warding off harmful ones. This same selective protection is used by manufacturers in a wide range of industries. For example, the automotive industry uses this concept when developing pressure compensation. As the name suggests, pressure is equalized between the inside of an enclosure and its surroundings. We see this when the human body compensates for added pressure when reaching deep depths in the ocean or high elevations while flying or scaling mountains; in these cases, pressure adjustments are often made by tasks as simple as swallowing or chewing gum.

Electronic components, of course, are not capable of relieving their own pressure, but still require compensation to protect themselves against a variety of external influences and substances. A solution had to be found that is both space and cost-saving, resulting in the creation of pressure compensation seals (PCS) for the technical and automotive industries.

Construction of a pressure compensation seal

Pressure compensation elements usually consist of several functional layers, the core of which is the integrated fine-pored membrane, possessing both hydrophobic and oleophobic properties. Membranes consist of materials such as expanded polytetrafluorethylene (ePTFE) or sintered polytetrafluorethylene (sPTFE). Depending on the area of application in automotive engineering, they can be supported by cover or labelling films. The membrane size for a Mini-PCS, a special pressure compensation element manufactured in a miniature version on special high-precision punching lines, with an adhesive ring, starts at 3 mm in diameter.

If the aim is to protect electronics in the engine compartment, the pressure compensation elements require much higher levels of protection, necessitating a special film to guard the membrane from mechanical stress and extreme weather conditions. Their use also protects the electronics from water ingress during steam jet or high-pressure cleaning.

These harsh environments require solutions that meet protection classes IP 67, 68 (protection against the ingress of water and dust), and IPX9K (resistance to high pressure and steam jets). Specially developed duct systems placed directly under the film provide ventilation, reliably ensuring pressure equalization in the housing. In addition, if required, the protective film can be marked with identification or consecutive numbering for better traceability.

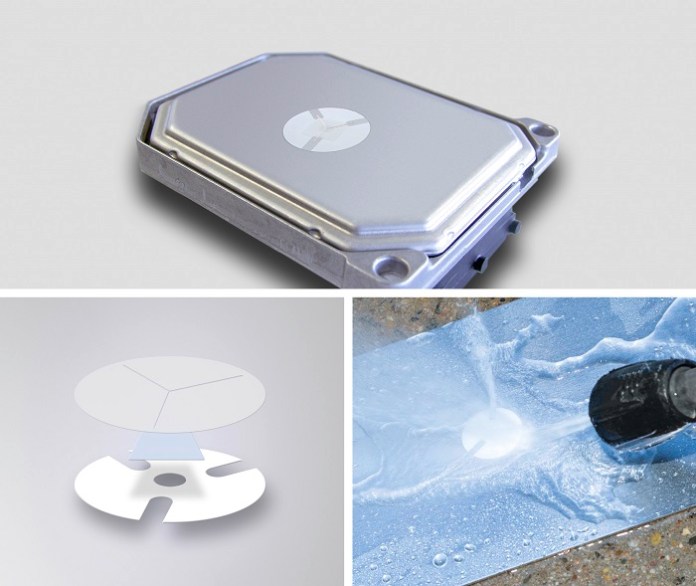

Various examples of pressure compensation seals from Schreiner ProTech, which ensure effective pressure compensation in housings— for example in lane change assist systems. (Image: Schreiner ProTech)

The functional principle

Automotive electronics are not located in a vacuum, but in a component housing surrounded by air. Due to vehicle operation and external influences such as temperature fluctuations or height differences, an over- (or under) pressure is created in the housing. The PCS membrane used is water- and dustproof, and at the same time permeable to air, which compensates for pressure differences. These differences may occur in the engine, steering and climate control, oil and water pumps, and sensitive sensor areas of the vehicle, to name a few.

The membranes are hydrophobic and oleophobic, meaning even liquids such as petrol or oil simply roll off. Dirt can neither clog the membrane nor penetrate the inside of the housing.

Pressure compensation elements are essential to ensure electronic functioning in housings, since an electronic failure could lead to a complete functional breakdown. Depending on the application area, a high degree of flexibility in product design is required in terms of shape, size, airflow and adhesive. Increased mechanical loads such as steam jet cleaning require particularly robust designs.

Depending on the type of vehicle, several hundred types of pressure compensation solutions are in use today, and ever-increasing vehicle sophistication and electrification will inevitably increase the demand for pressure compensation elements many times over.

Advantages and disadvantages of IPX9K resistant PCS variants

Self-adhesive high protection variants have several advantages over alternate solutions, including injection-molded pressure equalization variants whereby the membrane is installed via snap or screw. High protection PCS variants achieve a temperature application range of -40˚C to 150˚C, can be applied fully automatically, and require relatively few housing adjustments, since its average installation height is less than 0.5 mm.

By contrast, injection molding variants are typically screwed or clipped onto the housing through a predefined opening in the component, or via thread. The screw or snap-fit variants have the same temperature range as high protection PCS variants: -40˚C to 150˚C. The installation height is between 1 cm and 1.5 cm. From a mechanical standpoint, this is a very robust solution as the ventilation membrane is completely protected by the housing. However, if the housing breaks, the broken plastic particles can damage the electronic components and cause functional failure. Further disadvantages are the higher costs, the necessary housing adjustments — a certain wall thickness must be observed during housing planning and implementation — and application complexities.

Bonding and welding for lightweight construction

The pressure compensation element is attached to the component via a small opening, and must hold securely and reliably to fit optimally into the production process. This means that a fast, clean, and reliable application solution is required. There are several considerations pertaining to the fastening of the pressure compensation elements, including application, component substrate. and environmental exposure. Factors include material composition and condition of the component, temperatures, component contact parameters, the pressure compensation element with liquids or chemicals, process and cost considerations, necessary housing adaptations, application cycle time, and initial investment for the application or fastening unit.

A benefit of modern pressure compensation elements, applied by gluing or welding, is their weightlessness. Bonding is used more frequently in a variety of industries, including in automotive applications. At least 15-18 kg of adhesive and adhesive tapes are now in every vehicle. In this way, massive weight reductions could be achieved that would otherwise not have been possible, as bonded connections become a welcome alternative to heavy screws.

A key advantage is that many adhesives bond materials without damaging them, while screws weaken adjoining parts due to punctual loading, as stress peaks occur at the holes. Adhesives also provide additional strength due to greater overlapping of the parts being joined.

In the case of special plastic connections, the adhesive can sometimes be attached by outgassing the plastic; in these circumstances, an ultrasonic welding process is used. This membrane solution is used for pressure compensation elements whose membrane is made of PTFE (polytetrafluoroethylene). They can be applied by ultrasonic or thermal contact welding, which can be used to join all types of solid thermoplastics and synthetic fibers.

Ultrasonic welding uses a tool that generates high-frequency vibrations. In this process, the parts to be joined are set in kilohertz oscillation and generate heat at the contact surfaces through friction, causing the surfaces of the materials to melt and bond together. This connection has high thermal and chemical resistance and complies with IP protection classes 66 and 67 (protection against the ingress of water and dust).

The ultrasonically-weldable pressure compensation elements can also be dispensed directly from the roll, just like the self-adhesive pressure compensation elements with a diameter suitable for the required ventilation of the component. Their functionality is ensured via testing.

The DAE HighProtect pressure compensation seal compensates pressure differences reliably, and provides protection from harsh environmental conditions. (Image: Schreiner ProTech)

Pressure compensation seal plus nameplate

In many cases, a housing must not only be protected against overpressure, underpressure, and external influences, but also serve as proper marking. Multiple products and process steps slow down the application process considerably, make the procurement process more complex, and lead to an increased error rate.

By integrating the pressure compensation element into a nameplate, several process steps are condensed into one, saving time and reducing process costs up to 40 percent. Lower material costs, flexible and space-saving attachment and automatic application within the production chain are further advantages of the combination of pressure compensation element and type plate. In addition, it has significantly less error potential than other solutions, clear traceability is guaranteed throughout the entire supply chain by means of labeling, and the component is protected against functional failure.

It’s all about size

Membranes are also flexible in terms of size. The size of a diaphragm needed to reliably ventilate and vent a component depends largely on the housing design. Many factors must be considered, and the diaphragm of pressure compensation elements must be adapted to the respective application.

One factor is air passage volume, a method that measures and documents required airflow. The gas permeability varies depending on the type of membrane, the size of the free membrane area, and the membrane pore size. Testing ensures that the pressure compensation element provides the optimum air supply in the application and, thus, the desired pressure compensation in the component. The larger the component, the higher the required airflow. The required area depends on the type of material, the membrane manufacturing process, and the membrane pore size.

For example, new lighting technology such as adaptive lighting systems, laser light, or matrix LEDs, which have replaced halogen lights in vehicles, increase driving safety enormously by adapting to external conditions. Reliable and long-lasting lighting at night or in inclement weather conditions is necessary for safe driving. Pressure compensation elements protect the vehicle lighting from dirt and weather influences. They ensure safe pressure compensation, reduce condensation, and support the durability, quality, and luminosity of headlamps.

For optimal illumination, light surfaces and electronics housings are becoming larger, heightening the need for unique pressure compensation elements. Ventilation curves (airflow test) determine how large the ventilation volume must be for this modernized lighting technology to function optimally. Component ventilation can be ensured by a membrane with a higher air passage volume, or by several pressure compensation elements with a lower air passage volume.

Safety for assistance systems

Autonomous driving vehicles must react to external influences while communicating with their environment. An important prerequisite for this is the “tactile senses” of the assistance systems — the sensors. Indispensable for autonomous driving, they must work under extreme conditions.

A wide variety of technologies are available to help the car “see” the world around it. Modern driver assistance systems are able to detect critical situations quickly, warn the driver and, if necessary, actively intervene.

Here, too, pressure compensation elements ensure that assistance systems function reliably. Pressure transmitters are used in highly sensitive measurement and control technology. In them, pressure is converted in such a way that it can be measured mechanically or electrically. These components are often exposed to environmental influences that place exceptionally high demands on them. The electronics installed must therefore be reliably protected against rain, splash water, oil, or salt with optimal pressure compensation. This is where the pressure compensation element provides very valuable services in the smallest of spaces.

For example, a radar lane change assistant warns the driver while steering or turning if another car or other obstacle endangers the lane change. The driver is warned by a vibration of the steering wheel or a light display in the side mirror, and can abandon the lane change in time to avoid collision. A pressure compensation element ensures the smooth functioning of the lane change assistant by providing ventilation and protection for its sensor.

New systems, new solutions

Whether the vehicle uses camera, radar or light detection and ranging (LiDAR) systems, they all have one thing in common: they must function flawlessly in all weather conditions.

Especially in sub-zero temperatures, the sensors require more than just pressure compensation. They have to be de-iced as quickly as possible before driving and also remain free of ice while driving. This is only possible with a heater. Innovative heating foils based on printed electronics are installed in the immediate vicinity of the sensor. The functional foils are light, flat, and flexible, so they can be attached to the sensor in an extremely space-saving manner and, depending on requirements, generate a homogeneous or even inhomogeneous heating output for reliable de-icing.

The foils’ flexibility and the variable design of the conductor tracks allow the heating foil to be individually adapted in shape and size. The planar surface of the printed heating structures avoids the possible tracing of the conductor paths in the installed state – a haptic and optical advantage. Since the foils are not based on the standard variants available on the market but rather on the component itself, the customer’s installation work is considerably reduced, since no component-specific structural changes are necessary.

Wherever sensitive electronics, whether it is a radar system, tire pressure sensors, an airbag control unit, or adaptive driving light, are installed in a vehicle, their protection is also necessary. In the course of electrification and autonomous driving, these small, hidden helpers are becoming increasingly important. Pressure compensation elements and heating foils have become increasingly versatile at meeting these components’ disparate yet mission-critical needs.

About the author:

Adrian Marggraf is a senior product manager at Schreiner ProTech, a division of Schreiner Group, responsible for the areas of pressure compensation elements and functional die-cut and molded parts. He has overseen the company’s product marking and self-adhesive functional parts initiatives for the technical, electronic, and automotive industries for nearly a decade

Adrian Marggraf is a senior product manager at Schreiner ProTech, a division of Schreiner Group, responsible for the areas of pressure compensation elements and functional die-cut and molded parts. He has overseen the company’s product marking and self-adhesive functional parts initiatives for the technical, electronic, and automotive industries for nearly a decade

Advertisement