Executive Summary

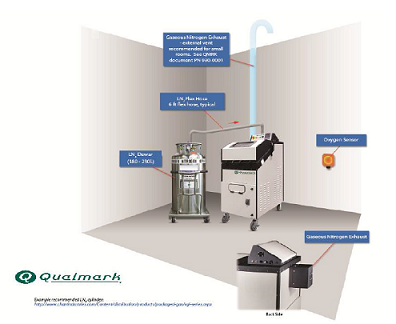

The HawQ system uses liquid nitrogen (LN2) to quickly cool products that are subjected to Accelerated Stress Testing processes such as HALT/HASS (see Figure 1). As the LN2 enters the test chamber, it quickly evaporates to gaseous nitrogen (LN2), and in the process, the volume of the gas expands to approximately 700 times its liquid volume. The nitrogen exits the chamber as a gas and is released into the ambient work environment near the chamber.

Gaseous nitrogen has no inherent toxicity. The clean, fresh air around us that we breathe every day contains approximately 78% nitrogen. However, excess nitrogen (>78%) in a workspace that has poor ventilation can lower the amount of oxygen, normally present in air at about 21%. Oxygen deficient atmospheres can create a hazardous work environment and are defined by a level of oxygen less than 19.5%. Adverse health effects may be minor with oxygen levels just below 19.5%. Severity of health effects increase as oxygen content drops, with loss of consciousness and death likely when oxygen is at or below 10%.

Oxygen deficient environments provide no warning of danger and situations can quickly become hazardous or fatal when the work environment is uncontrolled. The recommendations for controlling nitrogen hazards in this report are based on calculations and data collected during the use of the HawQ system. This study a) determined the amount of nitrogen gas released over time (generation rate) for both normal and worst case use scenarios, b) calculated the final room oxygen concentrations for normal and worst case use scenarios in three different room sizes with active ventilation and with no active ventilation, c) and verified the calculated room oxygen concentrations by performing onsite air monitoring for oxygen.

The findings of the study predicted that the use of the HawQ system would not result in an oxygen deficient atmosphere when:

Conversely, the study showed that use of the HawQ system could result in a low-oxygen atmosphere where there is inadequate active ventilation.

The final recommendations from this evaluation are:

• Oxygen sensors with alarms are recommended in rooms where LN2 is used, due to the lack of warning properties of oxygen deficiency.

• Use the testing chamber only in rooms that are ~2000 ft3 or greater with at least four room air changes per hour of general ventilation.

• When using the testing chamber in a room • The test chamber could be used with no minimum active ventilation in a room that is at least 8500 ft3.

• Installing ducting from the N2 exhaust port on the back of the test chamber to the outdoors or other well-ventilated area will eliminate the need for minimum ventilation requirements in the room.

• The use of fans, other air missing devices, or return air vents near the floor will eliminate the pockets of low oxygen resulting from poor air mixing.

Advertisement

Learn more about Qualmark Corp.