Product Roundup: Packaging & EMI/RFI Shielding

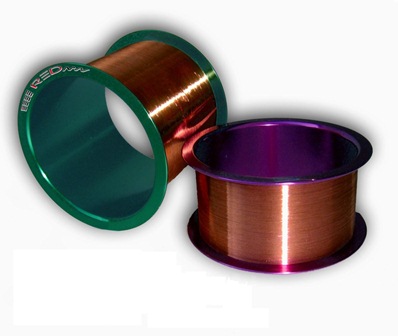

For packaging semiconductor devices, an important breakthrough was recently announced by RED Micro Wire (www.redmicrowire.com), a subsidiary of RED Equipment, in the area of semiconductor bonding wire. The company introduced a high-quality copper wire with glass insulation for use as a highly reliable alternative to gold wire, which has been known the standard.

Created using the newly patented Adar-Bolotinsky method for micro wire production, the wire can be used like traditional copper bonding wire but offers several advantages that make it more cost effective. Unlike traditional wires, RMW’s wires are cast, not drawn, which permits production of a soft metal core with a high-strength, ultra-fine glass coating with multiple advantages. The process is able to scale down to 4 μm, versus the 16 to 14 μm minimum of other wire solutions, enabling it to support high scalability for future designs.

The new wire also eliminates anti-oxidation issues, enabling a longer shelf life, and it supports larger spools to simplify materials management. In terms of electrical design, the wire inherently protects against “shorts” since it is coated and cannot accidently make electrical contact. This allows greater flexibility in design, with relaxed design rules.

Shimon Dahan, CEO, RED Micro Wire, notes that, “By providing cost-effective, low-diameter, insulated micro wire that is as ‘good as gold,’ we can help our OEM customers keep up with Moore’s Law, as they prepare their own designs for the future.”

RMW began sampling the technology with OEM customers in March, and intends to have full production by the end of the year.

Bomar Interconnect Products (www.bomarinterconnect.com) has unveiled RF-shielded coax connectors that handle up to 18 GHz. An addition to the company’s V-Bite RF edgeboard connector line, the 161VUs504EFT threaded RF connector features a bottom shield to help eliminate inductance. The connector is soldered directly to the pc board’s ground layer, providing not only consistent performance to 18 GHz but also higher manufacturing tolerances. Offered with 50-Ω impedance, the connector suits a broad range of high-power RF applications, and is priced at less than $16 each in 1,000-piece quantities.

Tech-Etch (www.tech-etch.com), an industry leader in etching, forming, heat-treating, and finishing of beryllium copper, is making available engineering services for the design of components made of the alloy. The mechanical and electrical properties of beryllium copper make it the material of choice for battery contacts, grounding clips, connector contacts, ESD clips, and shielding gaskets.

Tech-Etch’s in-house tool-and-die department produces bending tools capable of forming intricate sharp bends in tempers from annealed to full hard. Component parts are then heat-treated in an inert atmosphere to enhance spring properties. The treatment results in greater deflection, without compression set, while achieving close dimensional control. Finally, parts can be finished in many ways, with tin, silver, zinc, sulfamate nickel, electroless nickel, palladium nickel, and gold. Visit www.tech-etch.com/photoetch for a Precision Engineered Parts Capabilities Brochure and additional information.

Heilind Electronics (www.heilind.com) is now producing Autosplice RFI shield clips to allow placement of EMI/RFI shielding on pc boards without hand soldering. The miniature surface-mount clips are put on a board using standard high-speed placement equipment, eliminating extra holes and preserving board space.

The clips have four independent spring contacts that allow shield removal and replacement for rework and tuning. Originally designed for the handheld device market, they can be used in any application where space is a premium.

To help engineers who are trouble shooting diverse and many times elusive EMI issues, Leader Tech has published a free, six-page quick-reference guide that provides an overview of company products and capabilities. The company notes that it is extremely common today for products to integrate specialized components from several different manufacturers. Unfortunately, this trend has also led to many unanticipated radiated emissions and compliance problems. Independently these components perform as expected, but when they are installed in close proximity on the same circuit board, signal integrity and interference problems become apparent.

The new product reference guide from Leader Tech features three one-page sections that highlight shielding solutions for virtually any board, enclosure, or cable interference problem so engineers can quickly find one or more cost-effective solutions to their problem, thus reducing time to market, while lowering shielding expense and dealing with a single source. The Leader Techs Products and Capabilities Overview brochure is available for download from the company’s Web site, www.leadertechinc.com.

Advertisement

Learn more about Electronic Products Magazine