We’ve become heavily dependent on electronics systems during our lifetime, and recent experience tells us that we often need them most when disaster strikes. Trends show that the companies that supply enclosures to protect electronics are paying even closer attention to this fact and, therefore, are building products that are more secure than ever.

Personal survival

When it comes to enclosures, users have expressed many concerns — power capacity and distribution, weight handling, shock survival, thermal management — but one you haven’t often heard about is safety. But as Glenn Wishnew, Senior Manager, Product Management, for Rittal (www.rittal.com) points out, you should.

He notes that keeping your staff from opening a powered enclosure is one of the safest things you can do for them and your company. There is a standard that applies to this situation: UL508A for Flange Mount Disconnect Enclosures, promulgated by UL (www.ul.com), the commercial safety science company formerly known as Underwriters Laboratories. To find out if your equipment meets it, check the following:

1. The master and slave doors cannot be opened when the operator handle is in the “ON” position.

2. With the operator handle turned to “OFF,” the master door can be opened, allowing the slave doors to be opened.

3. The operator handle cannot be turned ON with the master door open.

4. Can you close the master door and turn the power ON with the slave doors open?

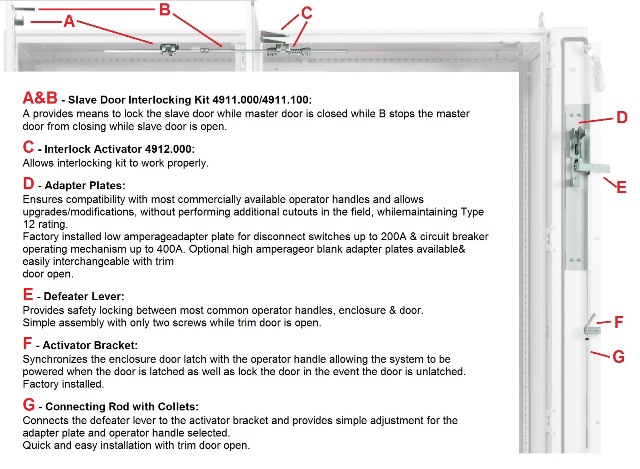

Whereas some enclosures may be able to pass the first three steps, Rittal believes its products are the only ones able to meet number 4, which is based on requirement 66.1.3 from the UL508A standard. Rittal’s TS 8 Flange Mount Disconnect system is the only one that does not allow an operator to throw the power switch ON unless all of the enclosure doors are closed, and so truly meets the UL508A standard. The reason is simple: The closure system is designed so that when any slave door is open, the master door cannot be closed and the power cannot be turned ON (Fig. 1 ). As Wishnew notes, “It seems like a simple thing to do, but only Rittal does it.”

Fig. 1: Rittal has designed a special interlocking mechanism to ensure that cabinets cannot be opened while the power is ON.

Big bang reality

Electronics find their way into some of the most hazardous environments in the world — settings that may have explosive atmospheres caused by gases, vapors, mists, or air/dust mixtures. Bud Industries (www.bud.com) recently introduced an ATEX-certified enclosure for use in such places, environments found in chemical and pharmaceutical processors, petrochemical sites, nutrients processors, wood and metal grinding operations, and other powder/dust operations.

Made of heavy-duty die-cast aluminum and sealed with a continuous silicon rubber gasket, the ATEX Series enclosures (Fig. 2 ) are rated for explosive atmospheres such as grain dust and conductive dust (Zones 21, 22). They are certified to ATEX II 2 G Ex e IIC Gb and ATEX II 2 D Ex tb IIIC Db, and are also UL-listed and rated at IP66 per the IEC 60529 standard. The aluminum body is powder-coated and captive screws in the cover are made of stainless steel. It has a service temperature range of –50°C to +135°C, allowing its use in a wide range of indoor and outdoor applications.

Fig. 2: Available in 10 sizes ranging from 2.95 x 3.15 x 2.24 in. to 14.17 x 6.30 x 3.54 in., Bud’s ATEX Series enclosure is suitable for harsh environments.

Per ATEX requirements, these enclosures will maintain their rating only if they are modified by the factory in India. If knowledge that the unmodified box met the requirements is sufficient, then Bud’s five-day modifications program can be utilized at no extra cost.

When the wind blows

With global climate change, the number of severe weather events has increased dramatically —and they are occurring in places where they haven’t in the past. Mindful of such events, W. L. Gore & Associates (www.gore.com) recently launched its next-generation PolyVent High Airflow to advance the performance capabilities of its Protective Vents Screw-In Series (Fig. 3 ).

Fig. 3: W.L. Gore & Associates’ PolyVent High Airflow vents were designed to help enclosures survive extreme weather conditions.

Engineered to handle the large pressure differentials caused by extreme weather conditions, the PolyVent High Airflow vents provide twice the airflow with the same ingress protection as Gore’s prior generation of high-airflow (HA) vents. The vents also improve O-ring design, which is UL-rated for flammability resistance.

For enclosures up to 50 liters, PolyVent High Airflow vents provide an advanced level of protection against the extreme conditions that can damage seals and outdoor electronics. “The new GORE PolyVent High Airflow delivers throughput of 4,000 ml/minute at 70 mbar pressure differential — basically double the airflow of our prior HA vent, which provided 2,000 ml/minute,” said Protective Vents’ Global Product Manager Torsten Eifler. “It achieves that level of airflow while maintaining the same reliable ingress protection. The GORE PolyVent High Airflow vents meet IP66, IP67, IP68 (1 hour immersion at 2 m) and IP69k (high-pressure steam) protection standards. The new vent also includes a specially treated membrane that provides oleophobic as well as hydrophobic resistance.”

Further, the vents incorporate another technology upgrade: an enhanced O-ring formulation that is rated UL 94 V-0 for flammability resistance. “An O-ring’s flammability resistance may seem a small thing, but at Gore, it is an important safety issue,” Eifler said. Vent caps and vent bodies already have earned UL 94 V-0 ratings.

Eifler expects that this new-generation High Airflow vent will be of particular value to two groups of outdoor electronics manufacturers: those that require higher airflow because they are designing larger enclosures of up to 50 liters free air volume, and those that require greater airflow to enable more cost-efficient design adaptations, such as thinner housing walls or less rugged seals.

Advertisement

Learn more about Bud IndustriesRittalW.L. Gore & Associates