By Alix Paultre, contributing editor

Batteries are an old technology that we’ve never been completely happy about, even as we improve them exponentially. The ability to take our gadgets with us using portable power storage has been a liberating thing since before the transistor radio. There has been a great deal of pressure placed on the battery industry lately between expanding legacy applications like portable devices and new areas like remotely piloted vehicles and electric cars.

Although advances in other related spaces, like more efficient electronics and lighter materials for vehicle bodies, have reduced some of this pressure on energy storage, the bottom line is that we will use all of the capacity provided. Luckily, the battery industry is rising to the challenge.

Infrastructure

The ability for a given storage solution to serve multiple applications is always a force multiplier, and at the recent Battery Show in Germany, ION Energy unveiled its UDYR portable, modular, and swappable battery pack that can go with you from your vehicle to your home or office. Not just a battery with a bunch of adaptors, the UDYR is supported by ION’s proprietary battery management system, intelligent software, and back-end analytics.

The solution uses smart sensors and algorithms that run in the background to improve battery performance and life while keeping the user updated on the battery’s state with wireless cloud connectivity. The 48-V lithium-ion battery is natively compatible with most electric two- and three-wheelers. UDYR comes equipped with Bluetooth and CAN bus communication for real-time data that can then be integrated into functionality like advanced battery analytics, warranty tracking, and vehicle location.

ION Energy’s UDYR portable, modular, and swappable battery pack can move from application to application.

Other big business moves in the space come from Lithium Werks , which has acquired the original A123 Systems manufacturing plants in Changzhou, China, the first to use NanoPhosphate technology in the form of cylindrical cells. As part of the transaction, Lithium Werks has taken over the customer relationships in China, Europe, and the United States along with the A123’s operations, staff, and product designs.

Lithium Werks also acquired the assets of Valence Technology, including customer relationships, global manufacturing, sales, and distribution locations along with all of Valence’s proprietary lithium-magnesium-iron-phosphate intellectual property portfolio, which also includes patents on high-voltage battery materials.

Higher-performance batteries

Advanced Battery Concepts has introduced a bipolar, lead-acid battery using a commercially viable “green” manufacturing process. Its bipolar construction results in lead batteries that are lighter, cost less, charge faster, and last longer than traditional lead batteries.

Called GreenSeal technology, the company’s solution offers advantages such as a uniform current density, increased active material utilization, a higher energy density, and simpler construction. Advanced Battery Concepts’ approach eliminates heavy metal grids and top-level lead connections for a significantly lighter battery with an increased cycle life of about 300% and a 50% reduction in average charging time.

Targeting smaller applications, Panasonic released a high-temperature, long-life nickel-metal-hydride battery with an ambient discharge range from –30°C to 85°C. The BK1100FHU has a rated capacity of 11,000 mAh, making it suitable for applications requiring high capacity and a wide range of temperatures like solar streetlights and remote vehicles.

Panasonic’s high temperature, long-life nickel-metal-hydride battery has an ambient discharge range from –30°C to 85°C.

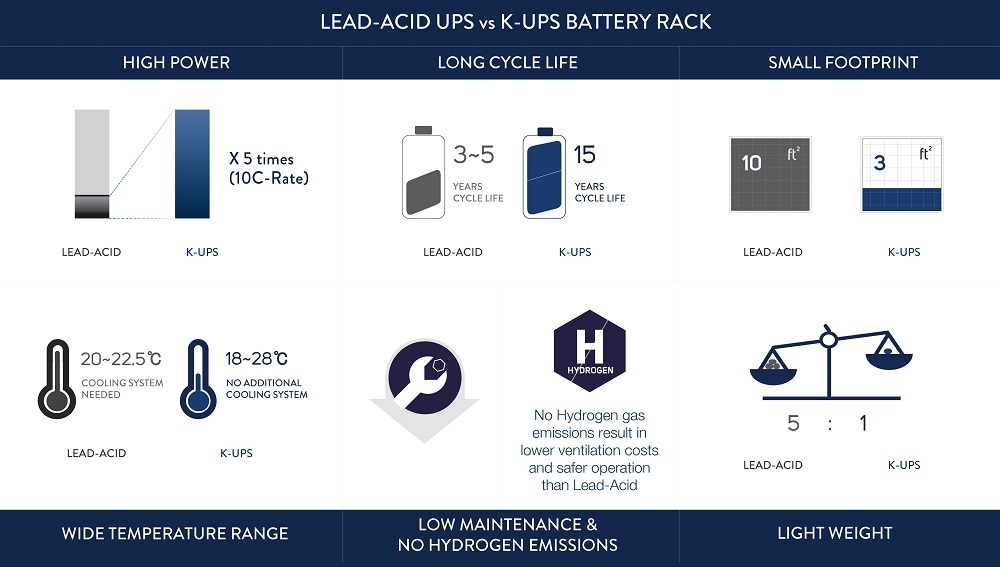

Serving facilities and factories, Kokam launched the K-UPS series of high-power uninterruptible power supply (UPS) battery racks, with their ultra-high-power lithium-nickel-manganese-cobalt-oxide (UHP-NMC) battery technology. These racks enable UPS system providers to meet the demand for lithium-ion-based UPS systems, delivering higher power for a shorter period of time at a lower cost than systems using lead-acid.

The increase in the use of backup generators decreases the need for UPS systems that can deliver a lot of power for a long time, with most now needing high power for periods of time lasting less than 15 minutes. In addition, lead-acid UPS systems have large footprints, are heavy, require high maintenance, need significant cooling and ventilation, and need to be replaced every three to five years.

The K-UPS battery rack has up to a 10 C-rate compared to a 2 C-rate for most lead-acid batteries or a 4 C-rate for most other lithium-ion batteries (C-rate measures the rate at which a battery charges or discharges relative to its maximum capacity). For example, K-UPS battery racks can provide up to 500% more power at the same level of battery capacity as most lead-acid UPS systems. K-UPS battery racks come in both two-pole and three-pole configurations at a variety of different voltage levels, providing design flexibility to UPS system providers.

Looking forward

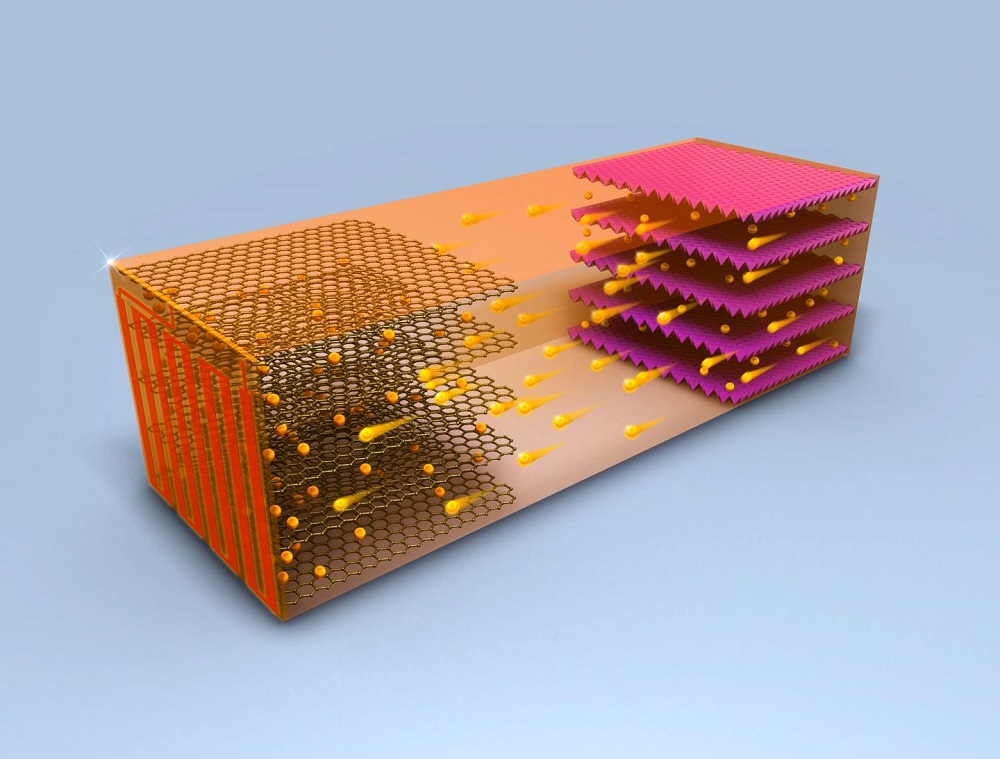

Many people in places like California can easily choose electric vehicles because they live in a warm climate, being that conventional lithium-ion batteries cannot be rapidly charged at temperatures below 50°F. However, a team of Penn State engineers has created a battery that can self-heat, allowing reliable operation regardless of the outside temperature.

Previously, the researchers developed a battery that could self-heat to avoid power drain at freezing temperatures. Now they have created batteries that allow 15-minute rapid charging at temperatures as low as –45°F.

A team of Penn State engineers created a battery that can self-heat, allowing reliable operation regardless of the outside temperature.

A team of Penn State engineers created a battery that can self-heat, allowing reliable operation regardless of the outside temperature.

Using a thin nickel foil with one end on the negative terminal and the other extending outside the cell to create a third terminal, the battery tech uses a temperature sensor to turn on a switch when needed to rapidly heat up the nickel foil and warm the inside of the battery. Once the battery’s internal temperature is above room temperature, the switch opens to enable rapid charging automatically.

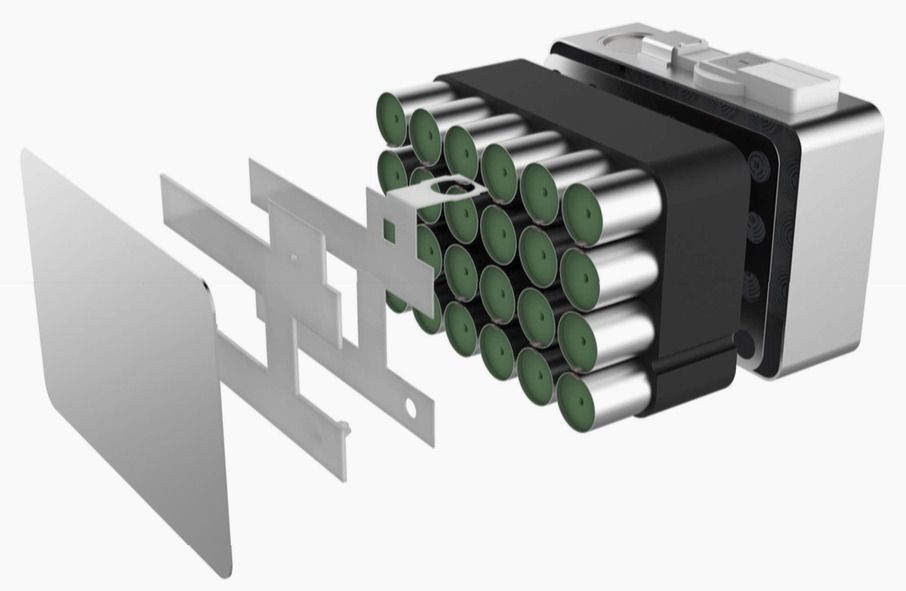

Christina Lampe-Önnerud, the so-called “Queen of Batteries,” recently founded Cadenza Innovation with the goal of making batteries cheaper and safer. Their focus is on the peripherals that make a battery usable in practical applications, the packaging, and interconnects. About 75% of the cost of a battery pack is for the cells themselves, with the remainder of the cost from the module and battery pack assembly.

Cadenza Innovation’s focus is on the peripherals that make a battery usable in practical applications, the packaging, and interconnects.

New York State’s energy research body NYSERDA announced that it will partner with Lampe-Önnerud’s company to build a grid-storage demonstration unit with a requirement that Cadenza batteries can eventually serve the electric grid at costs of $380/kWh. The size of Cadenza’s White Plains battery is modest: about 200 kWh in energy capacity and 50 kW in power capacity, which is enough to power 40 homes for a few hours.

The startup’s eventual goal is to provide super-cell technology to battery manufacturers around the world. Lampe-Önnerud said that later this year, Cadenza will be announcing a technology-licensing deal with a number of global battery makers.

Advertisement

Learn more about Electronic Products Magazine