Projected capacitive (PCAP) touch panels are rapidly becoming the user interface of choice in virtually every market, including products that are used outdoors. Designing PCAP touch panels to work in rugged, outdoor environments requires special considerations. Products designed for outdoor applications require high readability and durability even after thousands of hours of exposure to direct sunlight. The presence of water is another source of challenges for outdoor operation of a PCAP touch panel. In the marine industry, fresh water and salt water spray present unique challenges that require specialized designs to provide optimum performance.

Although there are a number of products and systems in the marketplace designed specifically for deployment in harsh, outdoor environments, incorporating a PCAP touch panel creates a new set of design challenges for the PCAP itself and for the display system as a whole. Some of the requirements for outdoor operation include high brightness (> 800 nits), high contrast ratio, a wide viewing angle and an extended temperature range, both high and low. The brightness and contrast ratio help to make the display more readable in outdoor conditions. Anti-Glare (AG) or Anti-Reflective (AR) treatments can be added to the display to reduce reflections. However, adding a PCAP touch panel to the display introduces new layers that can contribute to potential glare and reflection problems.

Sunlight readability

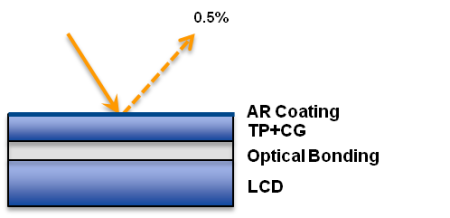

When light travels through air and strikes a glass surface or an LCD display, roughly 4% of the light is reflected off the surface as a result of the difference in index of refraction between the air and other materials. It’s typical to have 10% to 15% (seev Fig. 1 ) of total reflection from a touch panel bonded to a display when an air gap is present between the two. Internal reflections from within the touch panel itself can sometimes contribute a significant amount of additional total reflection, but this varies greatly depending on the number of layers and materials used to construct the touch panel.

Fig. 1: Reflections from a typical touch panel plus display with an air gap in between.

Anti-Reflective (AR) coatings are a great way to reduce surface reflections. There are low cost coatings consisting of a single layer that provide some reduction in reflection, and higher cost coatings with multiple layers that are tuned to reduce reflected light of different wavelengths across the visible spectrum. The benefit of AR coatings can only be fully realized when combined with optical bonding, which replaces the air gap between the touch panel and LCD with an optically clear adhesive, having the same index of refraction as glass. This eliminates the internal reflections that normally result from having an air gap in between the LCD and touch panel. A high performance AR coating combined with optical bonding can lower the total reflection to less than 0.5% (see Fig. 2 ).

Fig. 2: Reflectance of an optically bonded touch panel with an AR top coat applied

Another method for reducing reflections in outdoor displays is with Anti-Glare (AG) treatments. The process for creating an Anti-Glare surface typically involves etching the surface of the top glass layer (see Fig. 3 ).

Fig. 3: Anti-Glare etched surface

One of the side benefits of this process for PCAP touch panels is that fingers glide more smoothly across an AG etched surface and fingerprints wipe off more easily than on an untreated glass surface. However, AG treatments aren’t without drawbacks. The lower the gloss level, the more the underlying display image is diffused as well. Images will not be as crisp and a higher brightness backlight may be needed, which can increase cost and power consumption.

For touch enabled displays with an AR coating, it’s essential to add an Anti-Smudge (AS)/abrasion resistant coating to the surface. AS coatings are typically oleophobic and hydrophobic, which means they resist the adhesion of oil and water; this makes fingerprints and contaminants less visible and much easier to clean without chemicals. They also offer additional abrasion resistance.

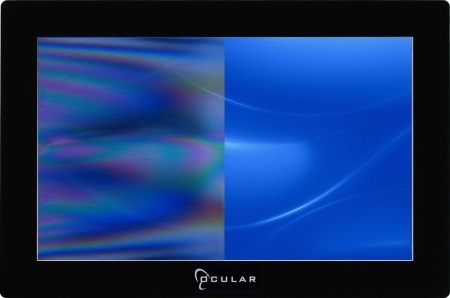

The sunlight readability of a display with PCAP is also affected by the touch panel construction. For film-based sensors, using traditional ITO on PET film, costly index matching and anti-reflection layers need to be built in to the sensor stack to reduce reflections from the internal layers. Some ITO replacements are being developed for better index matching which results in lower reflection and better contrast ratio than traditional film sensors. The other issue with sensor construction is the problem of birefringence, which can render displays with PCAP touch screens unreadable with polarized sunglasses. When a birefringent material is viewed between crossed polarizers, a “rainbow” effect occurs (see Fig. 4 ). If a PCAP sensor is made with a birefringent material such as PET film, this problem will occur because the top polarizer on the LCD and the sunglasses create crossed polarizers. Also, some touch panels utilize polarizers as a means of reducing reflections, which limits the angles from which they can be viewed with polarized sunglasses without the image becoming dim or disappearing altogether.

Fig. 4: Comparison of birefringent material used (left side of panel) vs. non-birefringent material (right side of panel)

Fresh Water and Salt Water

In some ways, PCAP is the perfect technology for an environment where water and other liquids might be present on the touch panel. A PCAP sensor operates through electric fields and not through any mechanical or physical contact. This allows PCAP touch panels to be fully sealed against any intrusion of moisture. Since the top surface layer of a PCAP sensor is typically glass, there is also no concern about cleaning or corrosion. These features have made PCAP a popular choice in the medical and marine markets.

The challenge with water on a PCAP touch panel is that a pool of water on the sensor can create coupling between the sensor electrodes, which may look like a touch to the controller. Salt water is more likely to register a false touch than fresh water: higher salinity results in greater coupling between the electrodes.

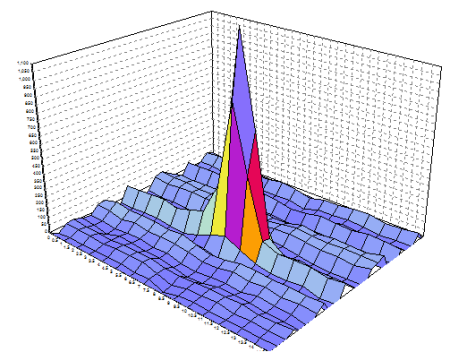

While it is possible for a pool of water to collect on the touch panel surface, particularly if the device is laying down flat, the more common water pattern would be a scattering of water droplets or a fine mist spread across the surface. Water drops have a smaller effect on the electric field because the smaller the drop size, the less it couples the electrodes together. However, once the amount of water on the panel reaches a point where the individual drops are touching each other and forming large chains of water, the response magnitude can reach the same level as an actual finger, resulting in false touches (Fig. 5 and Fig. 6 ).

Fig . 5: Actual touch response on a PCAP touch sensor

Fig. 6: Large chains of water response can lead to false touches

Salt water creates even more electrical coupling when an actual finger is present on the touch surface. As the finger moves around the surface of the touch sensor, the electrical coupling of the finger and salt water gets spread out along the path of movement. This creates a coupling trail that can be extremely difficult for the controller to separate from the actual touch (see Fig. 7).

Fig. 7: Coupling trail of salt water as the finger moves around the surface

There are several design changes the PCAP manufacturer can make to reduce, or even eliminate, these affects, including:

• Reduce the sensitivity of the touch panel. This reduces the amount of coupling that water can cause.

• Design the electrodes in the touch panel to reduce the amount of cross coupling caused by water.

• Configure the touch controller to filter out false touches caused by water.

Using a projected capacitive touch panel in an outdoor application presents unique challenges. The good news is that there are a variety of design choices that can reduce, or even eliminate, the problems caused by outdoor use. When designing a PCAP enabled outdoor product, the most important thing is to select a PCAP vendor who understands the inherent difficulties of the environment. The touch panel vendor can customize the panel design for the application and explain the various tradeoffs involved.

Advertisement

Learn more about Ocular LCD