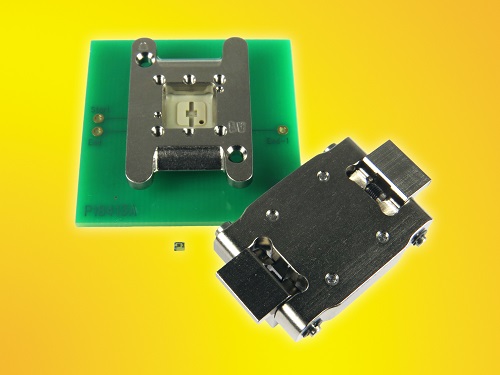

The new QFN socket from Ironwood Electronics features a unique contact design with outside spring and flat stamped plungers. The CBT-QFN-7056 provides a robust solution for burn-in and test applications while ensuring signal integrity in analog, digital, RF, Bluetooth, and medical designs.

The socket’s contactor is a stamped spring pin with 14.5-gram actuation force per pin and cycle life of 50,000 insertions. The self-inductance of the contactor is 0.98 nH, capacitance 0.067 pF, and insertion loss less than 1 dB at 31.7-GHz frequency. And the current capacity of each contactor is 2 A while socket temperature ranges from –55°C to 180°C.

Ironwood claims that the CBT-QFN-7056 socket has been designed to address the high- performance needs of various device sizes. The specific configuration of the package to be tested in the socket is DFN, 1.7 x 1.2-mm body size, and 0.5-mm pitch.

Ironwood’s new socket also features an IC guide for precise QFN edge alignment. To use it, drop the IC into the socket and close the removable lid by latching. A vertical force is applied by the integrated compression springs between the socket lid and compression plate. Moreover, the removable socket lid incorporates a quick installation method using a latch so that ICs can be changed quickly.

The socket can be used for hand test, screening modules, and custom burn-in applications with the most stringent requirements. It has been designed according to the JEDEC STD requirements and is available for all standard configurations. Ironwood also offers custom designs for the new socket.

The socket is mounted using supplied hardware on the target PCB without soldering. It uses an ultra-small footprint, and that allows inductors, resistors, and decoupling capacitors to be placed very close to the device for impedance tuning.

Advertisement

Learn more about Ironwood Electronics