By SOL JACOBS,

VP and General Manager, Tadiran Batteries

www.tadiranbat.com

Compromised design solutions involving unnecessarily large and heavy batteries often result in frequent battery replacements, as well as often-unforeseen expenses associated with transporting heavy batteries to remote, hard-to-access locations. These shortcomings are becoming increasingly magnified in an age of miniaturization.

Specify life/size/cost equations

In order to specify the ideal power supply for a battery-powered remote wireless device, various performance parameters need to be taken into consideration, including:

Cold and hot temperatures — Extreme temperatures can reduce battery voltage under pulse. If the battery has a limited temperature range and is deployed in a harsh environment, then an oversized battery may be necessary to compensate for expected voltage drop under pulsed load. An alternative solution may be to choose a bobbin-type lithium thionyl chloride (LiSOCl2 ) battery that features very high energy density and has been modified to deliver high pulses at extreme temperatures, thus eliminating the need for all of that extra capacity or voltage.

Operating voltage — Simple math indicates that it takes more than twice as many 1.5-V cells to deliver the same voltage as 3.6-V cells. Fewer cells translate into less size, weight, and cost.

Power vs. energy — This design challenge varies based on the application. For example, certain wireless devices are infrequently powered up, requiring high pulses for short bursts without exhausting much energy (capacity). Some typical high-pulse/low-energy applications include surgical power tools that operate for a few minutes and guided munitions that remain airborne for seconds. A surgical power drill, for example, can use four AA-size lithium metal oxide batteries to replace 12 alkaline cells. In a guided missile application, a small pack of lithium metal oxide batteries can outperform a much larger and costlier custom battery pack consisting of silver-zinc batteries.

Most battery technologies were never designed to produce a high power-per-energy ratio, thus requiring a large number of cells to compensate for their low-pulse design, resulting in excessive battery capacity.

Self-discharge — Certain battery technologies are prone to high self-discharge rates, losing up to 8% of their total capacity per month, thus requiring an oversized battery in order to compensate for the expected energy loss. Substituting a battery with a far lower annual self-discharge rate will permit the power supply to be smaller and could also eliminate the need for multiple battery replacements over the life of the device. Certain bobbin-type LiSOCl2 batteries feature an extraordinarily low self-discharge rate of 0.7% per year, thus allowing them to retain over 70% of their original capacity after 40 years. By contrast, a battery with a self-discharge rate of 3% per year (which may seem, at first, to be only incrementally higher) will exhaust 30% of its original capacity after just 10 years.

Cycle life — Most consumer-grade rechargeable lithium-ion (Li-ion) cells have a limited cycle life of approximately five years and 500 full recharges. If the device needs to operate beyond 500 recharge cycles without battery replacement, then extra cells are required in order to reduce the average depth of discharge per cell.

To address this challenge, an industrial-grade rechargeable Li-ion battery was recently developed that can extend battery cycle life up to 20 years and 5,000 recharge cycles. This industrial-grade rechargeable Li-ion cell is also capable of delivering high pulses and features an extended temperature range of −40°C to +85°C.

High pulse requirements — Remote wireless devices increasingly require high pulses to power advanced two-way communications and remote shut-off capabilities. Alkaline batteries are excellent for delivering high pulses due to their high rate design. However, these consumer-grade batteries also have serious limitations, including low voltage (1.5 V), a limited temperature range (0°C to +60°C), a high self-discharge rate that can reduce life expectancy to as short as one to two years, and crimped seals that may leak. Alkaline batteries may also need to be replaced every few months, which raises the total cost of ownership, especially for wireless devices that are deployed in remote, inaccessible locations.

Standard bobbin-type LiSOCl2 batteries are not designed to handle high pulses because they may experience a temporary drop in voltage when first subjected to this type of pulsed load: a phenomenon known as transient minimum voltage (TMV). However, a standard bobbin-type LiSOCl2 cell can be cost-effectively modified to deliver high pulses through the use of a patented hybrid layer capacitor (HLC).

The battery and HLC work in parallel, with the battery supplying long-term low-current power in the 3.6- to 3.9-V nominal range, while the single-unit HLC stores and delivers high pulses. This hybrid battery also features a unique end-of-life performance curve that enables devices to be programmed to deliver “low battery” status alerts.

Another way to minimize TMV is to use supercapacitors in tandem with lithium batteries. However, supercapacitors have major drawbacks, including bulkiness, high self-discharge rates (up to 60% per year), and a limited temperature range. Solutions involving the use of multiple supercapacitors also require balancing circuits, which draw additional current and add to the cost.

Low initial cost can be highly misleading — The total cost of ownership of a battery is not always accurately reflected in its initial cost. If the device is intended for long-term deployment, then the added labor and transportation expenses associated with more frequent battery replacements could add up, costing far more than the battery itself.

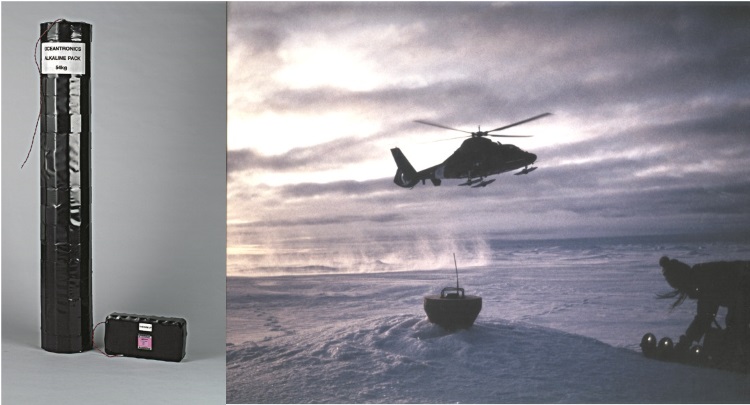

Fig. 1: Oceantronic’s GPS/ice buoy — which measures wind, temperature sunlight, and ice thickness — being retrieved by a helicopter near the North Pole. The original battery pack (left) consisted of 380 alkaline D cells and weighed 54 kg. The redesigned battery pack (right) uses 32 LiSOCl2 D-size cells and four hybrid layered capacitors to cut size and weight down to 3.2 kg while delivering the same operating life. (Right image courtesy of Sigrid Salo, NOAA/PMEL)

Compromise solutions involving added size and weight can also be highly problematic in difficult-to-access applications and extreme environments. For example, a compact, lightweight power supply is ideal for scientists working in frigid Arctic conditions (see Fig. 1 ) who have limited amounts of weight and volume that they can carry on missions. Lighter and less bulky batteries are also beneficial to utility linemen who spend all day carrying equipment up and down utility poles. Also, as a result of more restrictive UN and IATA shipping regulations, it is becoming increasingly expensive to transport lithium batteries.

Advertisement

Learn more about Tadiran