Taking advantage of ‘free’ energy that otherwise goes unused

Energy harvesting (EH) is the process of capturing energy that is generally overlooked and wasted, and then converting that energy into usable electric power. In a broad sense, EH describes the industrial solar, wind, and geothermal generators that produce massive amounts of energy, kW and MW levels. These macro-scale activities are at the forefront of the fight against global warming, but they aren’t the focus of this article.

Rather, this story covers the more common use for the term energy harvesting, the one referring to technologies for generating relatively tiny quantities of electrical energy (from several μW to several mW). EH obtains that power from small and generally overlooked and untapped energy sources that exist normally in the environments in which embedded systems are used (see Figure 1).

Figure 1: Introduction to energy harvesting. The electronics industry is discovering new ways to obtain small amounts of power—from several microwatts to several milliwatts—from sources found in the environments in which embedded systems are used.

Although the amount of environmental energy that various EH technology approaches aim to capture and convert into electrical energy is almost miniscule, substantial benefits are acquired by accomplishing the task. The main goal of energy harvesting is to enable electronic devices and systems to be maintenance-free and operate without fuel, disposable batteries, battery chargers or power cords. Since such products don’t have to connect to power lines, they can be used anywhere.

The major design issue for electronic engineers seeking to apply EH technology is that the circuits used must be low-power implementations—the lower the better.

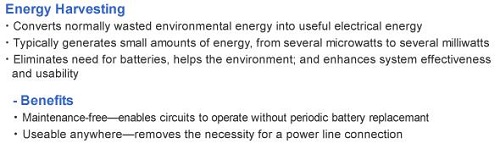

Some applications already exist for products powered by EH technology, and new ones are being invented at a rapid pace. Opportunities seem to exist in huge markets such as mobile devices, entertainment, health care, infrastructure elements, smart buildings, and cars and trucks (see Figure 2). In particular, wireless sensor networks for many applications can benefit hugely from advances in energy harvesting

Figure 2: Markets suitable for energy harvesting. A wide range of applications can benefit from the advantages enabled by energy harvesting, including those seen here. One type of device—wireless sensors—will be a big beneficiary of the technology because sensor networks are becoming increasingly common in the automotive, infrastructure, building automation and health care fields, among others.

Utilizing different methods for capturing energy normally wasted

Numerous unused energy sources exist for producing sufficient electrical power to run low-power embedded systems. Prime among them are mechanical energy (from the vibration, pressing, or striking of an object), thermoelectric energy (from temperature differentials), ambient radio wave, and in-room lighting. The following is a brief overview of these types of energy sources.

• Mechanical energy—Some materials will produce a voltage when made to vibrate, or when an external pushing or pulling force is applied to them. This physical phenomenon is referred to as piezoelectric effect, and materials that generate considerable voltage in this way are known as piezoelectric materials. It is also possible to harvest mechanical energy by designing an object such as a switch in such a way that the normal motion of operating it—pressing a key on a keyboard, for example—changes the magnetic flux of the core within a coil included built into the object. This flux change induces a current through the coil, capturing mechanical energy.

• Thermoelectric energy—Quite often, the temperature at one point of the surface of an object is different than what it is at a nearby point. By virtue of a physical phenomenon called the Seebeck effect, the temperature difference between those two points can be converted directly into an electric voltage. Certain semiconductors and metals with high Seebeck coefficients can transform temperature differentials into useful electric energy.

• Radio wave—Radio emissions are pervasive everywhere today. Electromagnetic energy from radio and TV broadcasts, mobile phone systems, wireless LANs, and other technologies surrounds us wherever we go, and only a small fraction of the energy in those transmissions is consumed by the intended receivers. EH devices equipped with rectenna can capture and convert some of this wasted energy into electricity.

• Indoor lighting—Like sunlight, indoor lighting can also be converted into electricity. The energy cells used for this purpose, however, have to be specifically optimized to work with the characteristic spectra put out by light bulbs. Although indoor lighting has long been a power source for wristwatches and handheld calculators, it doesn’t provide enough energy to be useful for most harvesting applications.

Two important facts should be mentioned here. First, the small amount of energy harvested for powering the electronic devices and systems doesn’t negatively impact the phenomenon or application that produced the energy because the miniscule quantity captured would otherwise be wasted. Essentially, EH technology adds value to a situation; it doesn’t remove value. Consider it an eco-friendly power-generation solution.

And second, it’s very possible that the source of the harvested energy might be intermittent, as it is when room lighting is turned on and off. Thus, if the electronic device or system being powered has to operate continuously or on a time schedule, it requires special power control circuitry and power storage capability to continue to run until the harvested source once again becomes active.

Lowering system management costs with networks of wireless sensors

Technologists expect that energy harvesting will be a suitable replacement for batteries in many low-power embedded-system applications. The shift to EH technology will take some time, though, due to the extremely small energy yields achievable and the cost of designing suitable electronic devices. Nevertheless, Renesas anticipates rapid progress in the area of wireless sensor systems in particular, especially for economic reasons. Specifically, the periodic replacement of batteries at sensor nodes imposes considerable maintenance expenses on deployed systems, with labor accounting for about 70% of the cost.

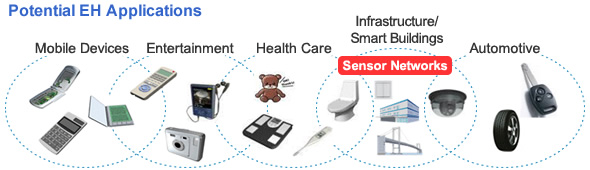

The huge potential market for wireless sensors that run on power derived from energy harvesting is dramatically illustrated by the infrastructure of a large building such as a hotel or hospital. Such structures generally have a complex mix of sensor-based electronic control systems (see Figure 3). For example, sensor networks typically generate situation data for air-conditioning control, lighting control, electric-power distribution, water drainage and recycling, elevator control, video security, and more. These systems use multiple types and sizes of sensors, devices that have diverse levels of communication capabilities.

Figure 3: Sensing arrays in building-management systems. Growing demand for increased fine-grained control of the many critical environmental, safety, security, power, lighting, water, waste and other infrastructure elements in large buildings is driving up sensor counts and their associated maintenance costs. Energy harvesting technology offers great promise for reducing costs and saving power in wireless sensor systems.

Harvested energy can be used to supply power to at least some of a building’s wireless sensors. However, before deploying new EH-powered components, engineers have to analyze mechanical, operational and electrical factors to verify suitability. Among the system-design issues they must consider are sensor sizes, the frequency of sensor use, support circuits, the onsite energy sources available and usable for harvesting, and the economics of the energy harvesting process.

Providing power control and power storage, if needed

As previously mentioned, developers of energy-harvesting schemes face two major challenges: (1) power output is very low and (2) it may vary considerably over time, Accordingly, to be effective in many applications, EH power sources may require special power control circuitry and power storage capability, depending on the application and the environment in which the EH system operates.

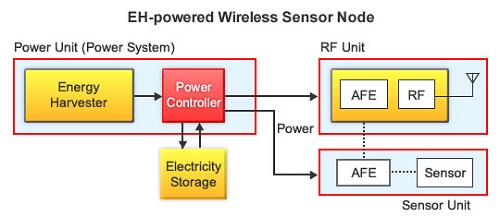

Power control circuitry for EH applications has to be able to produce sufficient voltage and current to drive its load (low-power MCUs, wireless communication devices, sensors, etc.). Beyond that requirement though, it has to be highly efficient in order to conserve as much of the harvested energy as possible. Further, its energy storage capability—typically obtained through the use of capacitors and rechargeable batteries—must have enough capacity to drive the electrical load during periods when harvestable energy is extremely low or nonexistent. Figure 4 illustrates a wireless sensor application containing a power controller and storage unit.

Figure 4: Block diagram of an EH-powered wireless sensor. The power controller manages the flow of electricity to the sensor’s electronics, while the energy storage unit—typically a capacitor and rechargeable battery—serves as a power reservoir that keeps the system running when insufficient energy is being harvested.

Developing energy harvesting technology requires group efforts

The massive task of developing and promoting EH technology necessitates the cooperation of many companies besides Renesas. Numerous global and regional consortia are taking up the challenge.

Europe is currently at the forefront in the advancement of marketable EH applications. Wireless and battery-less light switches, for example, are already available. These devices derive usable energy whenever a finger presses on the physical switch. Renesas is a member of the EnOcean alliance that promotes wireless application platforms throughout the region.

In Japan, we are one of the 13 founding members of the Energy Harvesting Consortium, which was formed in May 2010. Membership in this organization had grown to more than 50 companies by the end of 2012, reflecting great interest in this area of technology.

Making steady progress on EH R&D programs at Renesas

A number of Renesas R&D programs related to technologies and applications for energy harvesting are now underway. Work is currently ongoing on the following projects, among others:

• A wireless-communication power system driven by harvested vibration energy

• Component technologies for an radio wave harvesting system.

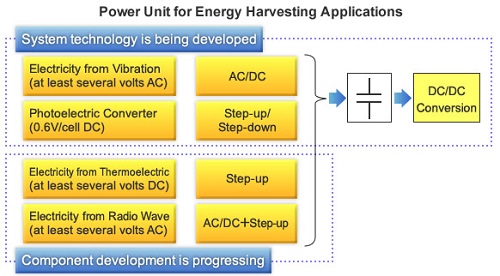

Additionally, our experts are forging close relationships with other organizations and firms in the global electronics community that support energy harvesting. They are contributing to mutual efforts to gather information and build cooperative links for facilitating the accelerated development of EH technologies and markets. Figure 5 illustrates power supply areas in which R&D is ongoing to make possible the deployment of practical EH applications.

Figure 5: Block diagram of power unit for EH applications. Renesas is developing the step-up circuits and other elements of power units needed for EH applications. Successful designs must deliver the supply voltages needed by chips, sensors and other components—and do so with maximum efficiency.

Implementing a wireless transmitter powered by energy from button presses

One of Renesas’ current EH development programs applies technology from Soundpower Corporation, a venture firm specializing in vibration harvesting. For several years we have been collaborating with the firm to build a technical base and to open new markets.

This R&D project has already produced a miniature wireless transmitter system. The system consists of a low-power 2.4GHz wireless transmitter module powered by Soundpower Corporation’s SHINDO BATTERY®. This commercially available battery converts button-press energy into electricity. With the existing system design, one press of the button supplies enough energy to transmit several bytes of data.

A primary aim of this ongoing project is to develop power circuits that can most efficiently supply power to the RF module. Another goal is to determine which capacitors and rechargeable cells are best suited for storing EH electricity in which the energy source isn’t sufficiently consistent.

In other programs aimed at developing vibration-harvesting wireless system businesses, Renesas is working with companies such as flooring manufacturers, system integrater, and others—firms that can provide expertise outside the scope of our own business activities.

Soundpower Corporation, for instance, has also developed Power Generating Floor™ that converts footfall energy into electricity that is used to send wireless signals. The flooring operates without batteries and can be used with any room shape. The energy generated can drive wireless electronic functions, etc. This opens opportunities for new systems, services, and markets.

Raising EH energy to the levels needed to drive circuits and devices

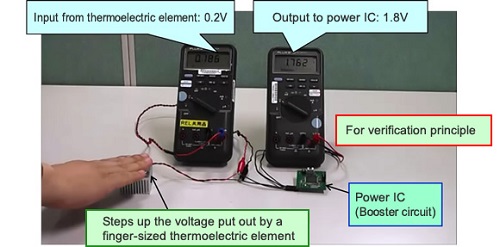

Renesas is actively developing component technologies required by harvesting energy from the various sources that are present in application environments. The one of the key issues on using energy harvesting as a power supply is an output voltage of only about 1/10th the voltage required to drive a microcontroller, sensor, or wireless transceiver. Thus, it’s essential that EH power systems be able to efficiently take the tiny harvested electric power and raise them to usable voltages.

To address this requirement, Renesas has developed an EH power system capable of stepping up a tiny input voltage of about 0.2V to about 1.8V, which is sufficient for powering an MCU. The new DC-to-DC converter chip has been used to boost the voltage generated by a finger-sized thermoelectric element (see Figure 6). This power system could be applied, for instance, to implement a small, battery-less, comfortably wearable medical pulse monitor. Such an application is a good example of how new technology creates new value for end users.

Figure 6: Under development: In this test setup, a prototype Renesas step-up power IC gets about 0.2V from a thermoelectric element and produces a 1.8V output that drives an MCU.

Anticipating a bright future for EH technology and its applications

The preceding discussion hints at just a few of the exciting opportunities, inventions and markets that EH technology will make possible in the coming months and years. The EH market is in its infancy and has a very promising future.

Renesas looks forward to building new business models in collaboration with progressive equipment makers and system vendors. Our vibration-harvesting power management technology, ultra-low-power MCU technology, and power management technology such as innovative step-up technology are poised to make important contributions to successful implementations in this emerging field.

If you do not see the information you need here, please contact us via the link below.

Advertisement

Learn more about Renesas Electronics America