While it’s already been proven that scientists can use a 3D printer for developing small masses of tissue for implants, Japanese researchers believe they are on the cusp of being able to use the technology to create fully functional body parts, including custom-made skin, bone, and joints.

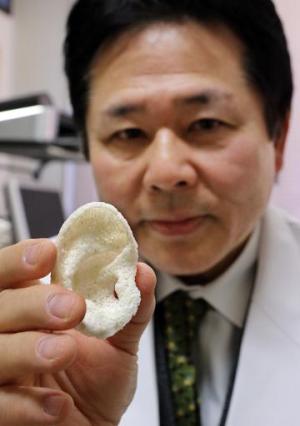

University of Tokyo Hospital professor Tsuyoshi Takato (pictured above) explained that his team has been working to create “a next-generation bio 3D printer” that can build up thin layers of biomaterials to form body parts.

In regards to the materials used, the team combines stem cells and proteins to trigger tissue growth, as well as a synthetic substance similar to human collagen for support.

Using a 3D printer, they’re able to mimic the “structure of organs” to an incredibly granular level, including things like the hard outer surface and spongy inside for bones.

In terms of timing, it takes a few hours for the printer to create the implant. Data regarding the size, placement, and more about the created body part, is sent to the machine using a Computer Tomography scan.

As a result of the information gathered beforehand, the 3D printed body part fit well on to the patient, and can be quickly assimilated by the person’s tissue and other organs.

“We usually take cartilage or bone from the patient's own body (for regular implants), but these custom-made implants will mean not having to remove source material,” Takato, a plastic surgeon by trade, explained.

Beyond replacing body parts in adults, this technology holds promise for children born with bone or cartilage problems. Often in these scenarios, synthetic implants are not applicable due to their body’s growth.

One hurdle standing in the way of Takato moving this technology forward is how to deal with the heat being generated by the 3D printers, as it has proven to damage the living cells and protein.

“We haven't fully worked out how to avoid heat denaturation but we already have some models and are exploring which offers the most efficient method,” he said.

Takato expects that he and his team will start clinical tests of 3D-printed skin in three years, after which they will proceed to test printing bones, cartilages, and joints.

Via Phys.org

Advertisement

Learn more about Electronic Products Magazine