By Warren Miller, contributing writer

3D bioprinters are revolutionizing the life sciences, but their prohibitive cost and complexity make them difficult for many people to gain access to them. Researchers at Carnegie Mellon University have developed a possible solution for researchers on a tight budget — an open-sourced, syringe-based bioprinter that can be incorporated into almost any standard 3D printer for a fraction of the cost.

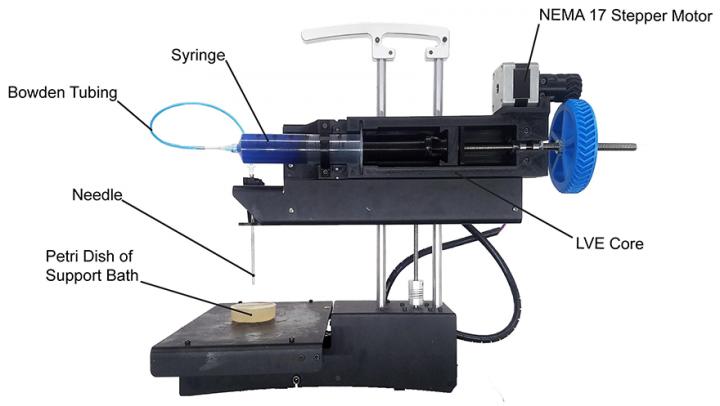

In a paper on the Large Volume Extender (LVE) published in HardwareX, the Carnegie Mellon team provided detailed instructions on how to install the mechanism and print biomaterials with it. The LVE employs a 60-mL syringe as an ink reservoir and can print fluids with a nozzle diameter as small as 100 μm. By making their design freely available to all, the researchers hope to make it easier for others to research and experiment with printing 3D biomaterials.

“Essentially, we’ve developed a bioprinter that you can build for under $500 that I would argue is at least on par with many that cost far more money,” said Adam Feinberg, co-author of the paper and material science and engineering and biomedical engineering associate professor at CMU. “Most 3D bioprinters start between $10K and $20K. This is significantly cheaper, and we provide very detailed instructional videos. It’s really about democratizing technology and trying to get it into more people’s hands.”

The syringe-based bioprinter can be incorporated into almost any standard 3D printer for a fraction of the cost. Image source: sciencedirect.com.

Until now, quality 3D bioprinting had only been done on a small scale. When working with smaller amounts of material, researchers could produce models with high levels of resolution. As the volume increased, however, the models lost quality and consistency. The LVE can produce models as large as the human heart without sacrificing detail or resolution.

The printer can be used with a variety of bio-materials, but complex cells that require a significant amount of connectivity — like the muscles and nerves around a human heart — are not yet on the list. It might not take very long, however, for printers to be able to connect these types of cells together or even to actually create simple muscles and nerves. Once that is possible, just imagine the types of things that could emerge from a 3D printer. Perhaps small micromechanical devices combined with biological cells, muscles, and nerve tissue will be the way that miniature robots will be created.

Of course, the most complex connectivity at the cell level is found in the brain. It would probably take many more innovations to be able to 3D print even part of a brain, but I’m sure that, somewhere in the world, there are teams of scientists thinking about it.

Getting back to reality, the open-sourcing aspect of this new design shouldn’t be overlooked. Making this kind of technology available to the world could be a titanic step forward for biomedical research. “We envision this as being the first of many technologies that we push into the open-source environment to drive the field forward,” said Feinberg. “It’s something we really believe in.”

Advertisement

Learn more about Electronic Products Magazine