A team of researchers at the University of Maryland has taken a most interesting approach in their quest to create the smallest energy storage component ever.

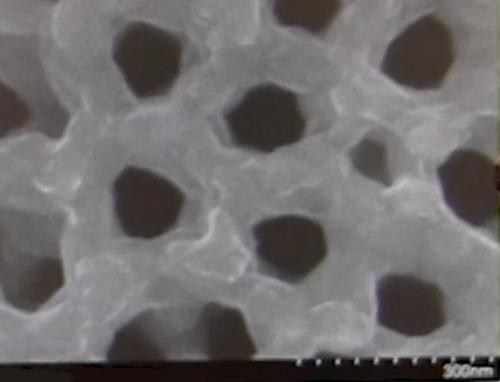

They created a working battery using a ceramic sheet filled with holes.

Specifically, a billion holes.

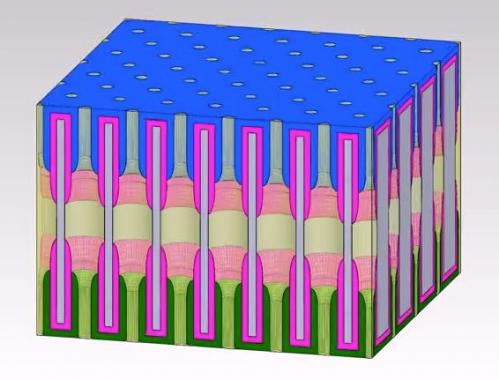

The hole-structure is referred to as a “nanopore” and each one is shaped like the other, which allows designers to fill the sheet with these holes super efficiently. Additionally, each end of the nanopore is treated with nanotubes for the purpose of collecting electrical charge conducted by the liquid electrolyte filling the pore.

This results not only in each hole acting as its own electrochemical storage device, it also helps self-align the electrodes within each nanopore, thereby enabling closer and more controlled spacing between the electrodes than today’s state-of-the-art batteries.

The UMD approach presents a worthwhile alternative to interdigitated electrodes that require complex three-dimensional geometries with greater spatial heterogeneity. Their structure, in comparison, is composed of an array of nanobatteries connected in parallel, with each one having an anode, cathode, and a liquid electrolyte confined within the nanopores of anodic aluminum oxide, thereby acting as an all-in-one nanosize device.

The capacity retention of this fuel cell is 95% at 5 degrees Celsius, and 46% at 150 degrees Celsius with a 1,000-cycle life. As per first author Chanyuan Liu, a graduate student in materials science and engineering, the device can be fully charged in 12 minutes.

Approximately speaking, the space inside the holes is so small that the room they take up, altogether, is no more than a grain of sand.

Now that the team has a working battery, they are working on improvements that could make the next version 10 times more powerful.

In terms of next step toward commercialization: testing out the team’s various strategies for the most efficient way to manufacture the battery in large batches.

Read the published report in Nature.

Via UMD

Advertisement

Learn more about Electronic Products Magazine