Health sensors are on an evolutionary course that will someday see them attached directly onto the surface of a human organ to monitor miniscule electrical signals and provide detailed information that’s otherwise unavailable. As it stands, compiling a health analysis on organ health requires large-scale imaging (or invasive surgery) and is impossible to accomplish over an extended period of time.

But now, a solution is closer than we think; a team of researchers based at several Japanese universities have created gel-based sensors that produce a stable, non-allergic contact between targeted tissue and electronic sensors, essentially monitoring electrical activity while adhering to the slimy insides of the body. What’s more, the new sensors have already yielded positive results when tested on the still-beating hearts of rats, successfully measuring its strain and electrical activity for three consecutive hours using an electric array of highly sensitive, stretchable sensors.

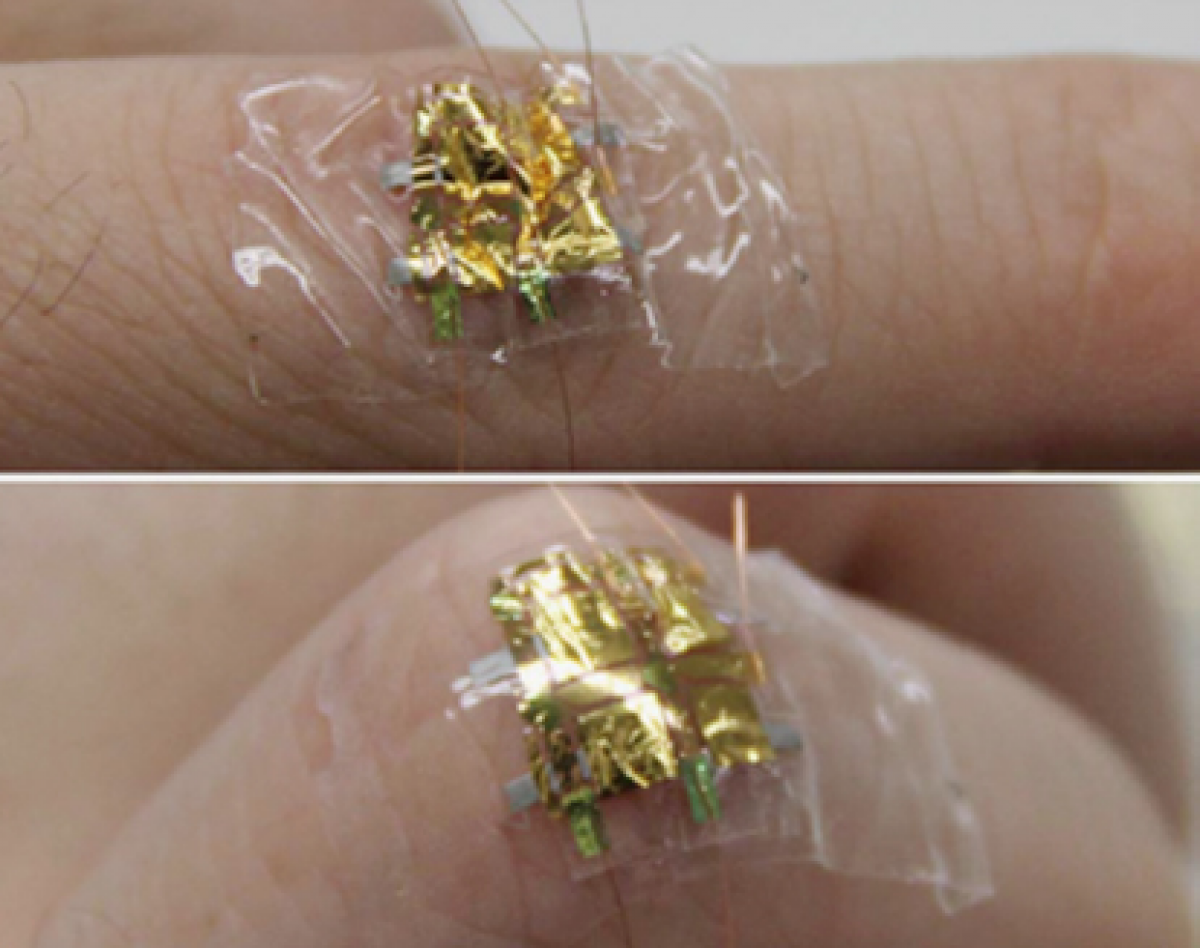

Typically, biological tissue’s tendency toward wet and slippery makes it very difficult to form a stable interface between the tissue and the electrical probes; this issue worsened if the tissue exhibits motion, such as in the case of the heart. The researchers overcame this challenge by designing and fabricating a thin, stress-absorbing sensor grid made of polyethylene terephthalate film that is only 1.4 microns thick and held together by polyvinyl alcohol gel. The prototypes themselves feature 144 sensors distributed 4 mm apart over a five inches squared surface.

The materials used to form the gel have all been previously used in other internal medical applications, so there’s no risk of sudden tissue rejection. Nonetheless, it’ll be a while before prototypes subjected to human testing, assuming the scientists devise a method of long term attachment beyond three hours. And if the testing is a success, perhaps we’ll start to see sophisticated pacemakers capable of reporting on the minutest changes in heart beats and other forms of a biotech.

Advertisement

Learn more about Electronic Products Magazine