A team of researchers from Harvard University has successfully created the world’s first entirely 3D-printed organ-on-a-chip with integrated sensing.

The pseudo-organ, if you will, was built by a fully automated, digital manufacturing procedure. It can be quickly fabricated with customized factors so as to allow researchers to collect data for short-term and long-term studies.

This breakthrough marks the first step toward achieving a much larger goal — being able to manufacture organs-on-chips, also referred to as microphysiological systems, which match the properties of a specific disease or an individual patient’s cells.

“This new programmable approach to building organs-on-chips not only allows us to easily change and customize the design of the system by integrating sensing but also drastically simplifies data acquisition,” said Johan Ulrik Lind, first author of the paper and postdoctoral fellow at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS).

“Our microfabrication approach opens new avenues for in vitro tissue engineering, toxicology, and drug screening research,” said Kit Parker, Tarr Family Professor of Bioengineering and Applied Physics at SEAS, who coauthored the study. Parker is also a Core Faculty Member of the Wyss Institute.

The purpose of an organ-on-chip is to mimic the structure and function of tissue native to the human body; industry experts have identified it as a promising alternative to animal testing.

To date, Harvard researchers have developed microphysiological systems which mimic the functions and microarchitecture of a human’s intestines, lungs, heart, and tongue. The fabrication and data collection process for these systems are laborious to develop, and expensive to execute. They’re built-in clean rooms using complex, multi-step lithographic processes, and data collection is performed via microscopy or via high-speed cameras.

“Our approach was to address these two challenges simultaneously via digital manufacturing,” said Travis Busbee, coauthor of the paper and graduate student in the Lewis Lab. “By developing new printable inks for multi-material 3D printing, we were able to automate the fabrication process while increasing the complexity of the devices.”

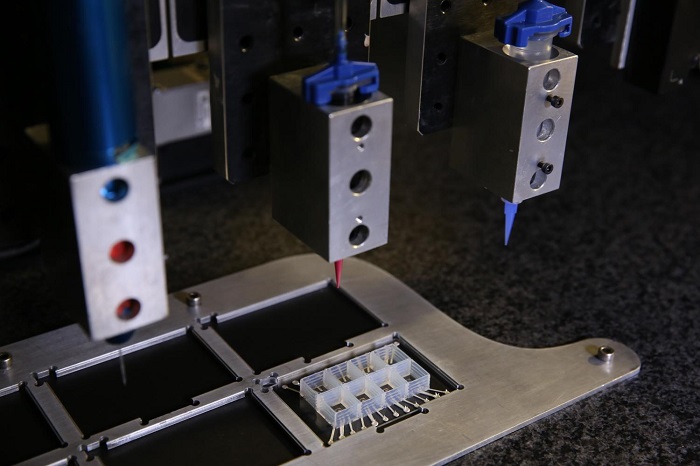

The researchers created six different inks that integrated soft strain sensors within the microarchitecture of the tissue. In a single, continuous procedure, they then 3D-printed those materials into a cardia microphysiological device (a heart on a chip) with integrated sensors.

“We are pushing the boundaries of three-dimensional printing by developing and integrating multiple functional materials within printed devices,” said Jennifer Lewis, Hansjorg Wyss Professor of Biologically Inspired Engineering and coauthor of the study. “This study is a powerful demonstration of how our platform can be used to create fully functional, instrumented chips for drug screening and disease modeling.”

The chip, it’s worth mentioning, has multiple wells, each with separate tissues and integrated sensors; this design allows researchers to study several of the engineering cardiac tissues at once.

For the purpose of demonstrating the device’s efficacy, the team performed drug studies and longer-term studies of gradual changes in the contractile stress of engineering cardiac tissues; the normal time frame for this sort of work is several weeks.

“Researchers are often left working in the dark when it comes to gradual changes that occur during cardiac tissue development and maturation because there has been a lack of easy, non-invasive ways to measure the tissue functional performance,” said Lind. “These integrated sensors allow researchers to continuously collect data while tissues mature and improve their contractility. Similarly, they will enable studies of gradual effects of chronic exposure to toxins.”

“Translating microphysiological devices into truly valuable platforms for studying human health and disease requires that we address both data acquisition and manufacturing of our devices,” said Parker. “This work offers new potential solutions to both of these central challenges.”

Demonstration and creation process of the heart-on-a-chip below:

To learn more, read the team’s full study, Instrumented cardiac microphysiological devices via multimaterial three-dimensional printing , which was published in Nature Materials.

Advertisement

Learn more about Electronic Products Magazine