By Carolyn Mathas, contributing writer

There is a continued focus in the power inductor and transformer industry segments on improved efficiency, high accuracy, miniaturization, and stability at extremely high operating temperatures. Common improvements include lower resistance and smaller footprints but also a slim profile, higher power density, and changes in packaging. Here are 10 inductors and transformers, in no specific order, that highlight those trends:

Vishay Intertechnology has claimed a 50% reduction in direct current resistance (DCR) over typical power inductors with its IHSR-1616AB-01 high-saturation commercial inductor. The inductor offers DCR tolerance options of either 5% or 3% for high-accuracy current sensing in multi-phase power supplies. The device saves space, enables designers to create slimmer end products, and delivers temperature stability in industrial, telecom, and computing applications.

The inductor is housed in a 1.2-mm, low-profile 4 × 4-mm 1616 case. Competitively, the inductor offers a low typical DCR down to 1.15 mΩ with an inductance range up to 0.068 µH, providing higher current density than competing technologies. As a result, the device can replace larger single-turn ferrite inductors to save space, enable slimmer end products, and deliver better temperature stability for multi-phase, high-current power supplies and filters in computer, industrial, and telecom applications. Optimized for energy storage in DC/DC converters and high-current filtering up to the self-resonant frequency (SRF) of the inductor, it handles high transient current spikes without saturation.

The Vishay IHSR-1616AB-01 commercial inductor delivers a 50% reduction in DC resistance over typical power inductors.

Vishay also unveiled the IHLP‑6767GZ‑8A, an automotive-grade IHLP series of low-profile, high-current inductor that saves precious space under the hood. The rugged device delivers a continuous high operating temperature to 180°C, suitable for filtering and DC/DC conversion in engine and transmission control units, diesel injection drivers, and under-the-hood applications. It provides noise suppression for motors, windshield wipers, power mirrors and seats, HID and LED lighting, and heating and ventilation blowers.

AEC-Q200–qualified, the IHLP-6767GZ-8A inductor features high efficiency with typical DCR from 0.89 mΩ to 52.7 mΩ and a wide range of inductance values from 0.47 µH to 47.0 µH. The device provides a rated current to 76.0 A and handles high transient current spikes without saturation.

Also addressing automotive and other rugged/harsh-environment applications, Coilcraft, Inc. launched two series of high-current shielded power inductors. The XAL7050 series features inductance values from 22 µH to 47 µH and current ratings up to 5.5 A. A low DCR ensures greater efficiency. Its rugged construction minimizes audible buzzing. Qualified to AEC-Q200 Grade 1 with RoHS-compliant tin-silver-over-copper terminations, the inductors offer a maximum reflow temperature of 260°C. Tin-silver-copper and tin-lead terminations are also available. The inductors offer an operating temperature range of –40°C to 125°C. If lower inductance values but an identical footprint are required, the XAL7030 Series provides up to 60-A current handling, an exceptionally low DCR of 1.5 mΩ, soft saturation, minimized audible buzzing, and an inductance range of 0.16 µH to 10 µH.

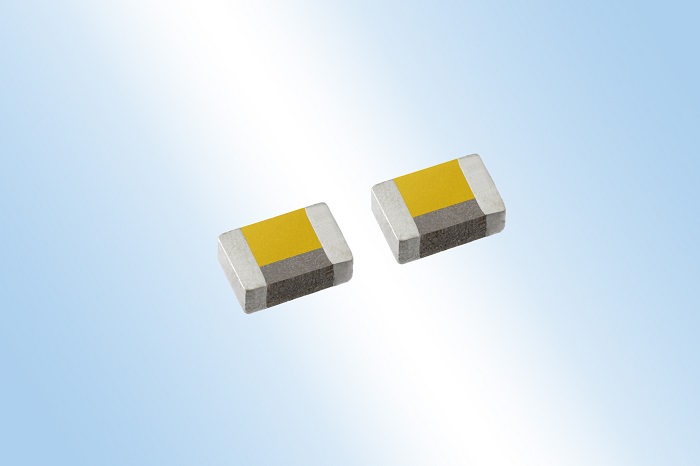

TDK Electronic Components ’ new miniature thin-film power inductor, the TFM201208ALD, handles 4% higher currents and provides a 5.5% lower DC resistance at 85 mΩ compared with competitive products. The inductor delivers the highest possible power-conversion efficiency for lightweight mobile devices. The unit has a rated inductance of 1.0 µH. Although size is its distinct advantage, it offers electrical stability and heat resistance and minimizes electrical noise compared with others in the class. With the best power-conversion efficiency, mobile devices achieve maximum battery life.

TDK’s thin-film power inductors can handle 4% higher currents and offer a 5.5% lower resistance than conventional products.

TT Electronics has introduced the HA66 Series SMD power inductors for use in high-power-density applications such as powertrain, engine control, transmission control, LED drivers, ABS braking systems, and radar and camera-control systems, in which size is a critical factor. Used in DC/DC converters with switching frequencies up to 3 MHz and electromagnetic interference (EIMI) and low-pass DC filters, they are also suitable for industrial automation systems as well as DC/DC converters. The series offers a range of 38 inductors with inductance ratings spanning 2.5 µH to 220 µH, DC resistances from 0.018 to 0.820 Ω, and Irms values from 1.22 A to 11.2 A.

When high reliability is the primary goal even in harsh military environments, API DELEVAN’s Series HRSPD127 shielded surface-mount power inductors deliver. The devices stand up to mechanical shock, high-frequency vibration, and solder and moisture resistance and meet MIL-STD-202, MIL-PRF-27, and MIL-PRF-83446 requirements. Features include an operating temperature range of –55°C to 130°C and inductance values from 2.2 µH to 1,000 µH.

Larson Electronics LLC introduced the MT-BBT-240V-208V-70.8A, a single-phase buck and boost 240-V primary/208-V secondary step-down transformer. In this device, most of the load voltage is directed through the transformer, resulting in a smaller, quieter, and highly energy-efficient unit. This unit is mountable on the wall or floor. It features 180°C insulation with a 115°C temperature rise. Its core is made from cold-rolled steel laminations that are coated to protect against moisture, while magnetic copper winding improves performance. With an isolated power source for additional safety and protection against equipment failure, applications include air conditioners, heating elements, lighting systems, and motors wherever additional power at higher voltages is required.

Power Integrations designed the SIT12xxI transformer specifically to complement its SCALE-iDriver family of gate drivers, simplifying DC/DC converter design for industrial use. By combining the transformer and SCALE-iDriver ICs, the need for additional voltage regulation is eliminated. The galvanically isolated SIT12xxI transformers deliver the correct voltage and power for the gate drivers. The transformer’s “isolated wire-in-wire” structure also delivers high reliability, strong isolation, and low coupling capacitance. Given the UL and VDE approval of the transformers, the safety certification process is simplified, translating into reduced time to market. The transformers are lightweight at only 9 grams, have a highly flexible and compact footprint, and offer high resistance to shock and vibration.

TDK Corporation unveiled the B82806D0060A Series of EPCOS transformers with sufficient output for power-over-Ethernet (PoE) applications. An output of up to 60 W meets the IEEE 802.3bt specification requirements. Existing solutions that meet the basic PoE and PoE+ standards rely on two pairs of cables and have outputs of 15 W and 30 W. To meet the PoE++ standard, the new series features four pairs of cables and supports devices with higher power requirements. Applications include lighting controllers, fire alarm systems, and smart-building access control.

The electrical insulation of TDK’s transformers complies with UL 1446 class 130 (B), enabling them to withstand a high-voltage test between the primary and secondary sides at 1,500 VAC, 50 Hz for one second. DC resistance down to 3.5 mΩ ensures higher efficiency and makes the transformers appropriate for active clamp forward converter topologies.

Vishay Intertechnology, Inc. offers a series of miniaturized gate-drive transformers that are sufficiently compact for high-power military and aerospace, industrial, and medical applications. With dimensions of 20.57 × 18.42 mm and a low 11.4-mm profile, the new Custom Magnetics’ MGDT series uses 40% less board real estate, and its profile is 33% lower than traditional solutions. The planar package is a departure from traditional bobbin and toroidal winding technology and is key to its ability to meet or exceed most safety requirements.

Available in either surface-mount or through-hole terminations and multiple turn ratios, the surface-mount MGDT series devices are the industry’s smallest to provide 8-mm creepage and clearance. The devices deliver high dielectric strength to 3,750 VAC from drive to gate, leakage inductance of 0.5 μH, and a continuous operating temperature range of –40°C to 85°C.

Premier Magnetics announced the PM-PTxxx Series of frequency-optimized planar transformers based on Premier’s unique approach to circuit board windings, resulting in optimization of transformer impedance and interwinding capacitance effects. Models feature ratings up to 250 W for applications such as forward converter, full-/half-bridge, and active clamp, using switching frequencies ranging from 200 KHz to 700 KHz. The PT Series options all deliver excellent isolation (up to 2,250 VDC) and operate over a –40°C to 125°C temperature range with efficiency of up to 99%. Based on their planar construction, rather than a classic wire-wound approach, they provide exceptional heat dissipation. They are suited for power conversion in switch-mode power supplies and in electric vehicle, industrial, aerospace, and solar applications.

Advertisement

Learn more about Electronic Products Magazine