As the additive 3D-printing process continues to advance, consumer printers will someday gain the ability to compete with fabrication plants, revolutionizing manufacturing to such an extent that it will be reminiscent of the introduction of the assembly line. 3D-printing is already spawning robots, guns, pizza.

The upcoming generation of multi-material machines will further expand capabilities by compositing multiple forms of plastic, metals, silicates, and more. But, the current challenge for innovators is maximizing what they can build with the current technology’s single material limit. One mechanical engineer and assistant professor at Princeton University sought to break this limitation by mixing and matching five different materials that have all been 3D-printed, to create a fully functional LED on par with those used in the iPhone.

“In the world of 3-D printing, the big push is to try to print with multiple materials at once,” says mechanical engineer Michael McAlpine. “What they really mean, usually, is printing in two different-colored plastics.”

McAlpine and his colleagues from Princeton claim that their group is the first to create an actual working diode, rather than printing a breadboard of electronics and then plugging LEDs into it — something McApline claims other did. To be more specific, the light-emitting diode that McAlpine and his team crafted is actually a quantum dot LED, a type of LED similar to what’s built into television and portable electronics’ screens.

So how’d this group pull off the feat? Easy — they invested between $10,000 and $20,000 and six months of labor assembling a custom printer capable of sandwiching five layers of metals and polymers.

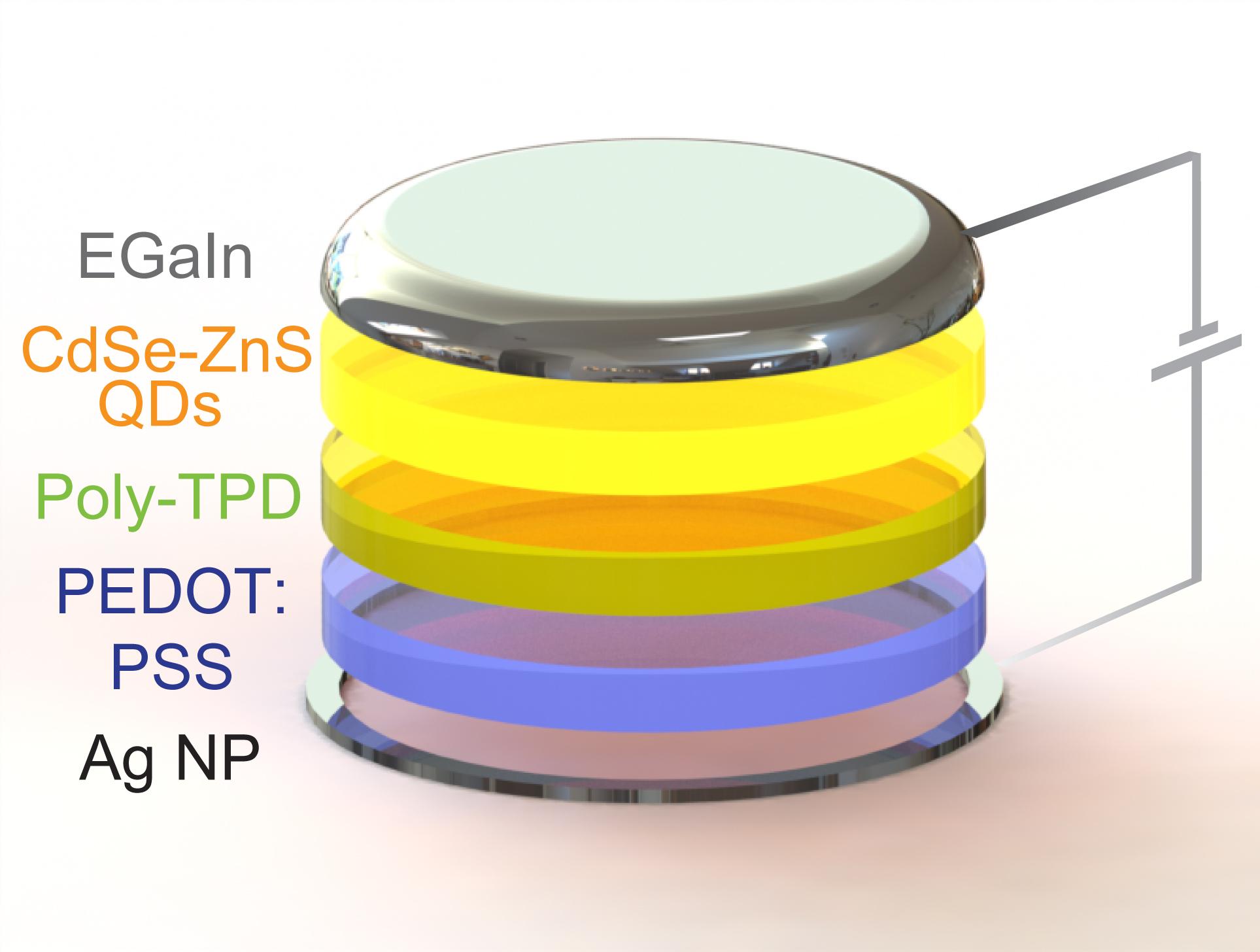

With that said, the five layers of materials used to fabricate the LEDs include a bottom layer made from a metal ring of silver nanoparticles (used as the metal contact in the electric circuit). On top of this sits two polymer layers: one made of PEDOT: PSS (Poly(3,4-ethylenedioxythiophene) Polystyrene sulfonate) and the other of Poly-TPD (Poly[N,N’-bis{4-butylphenyl)-N,N’-bis(phenyl)- benzidine]). Above the two polymers resides quantum dots made of CdSe-ZnS QDs (cadmium selenide nanoparticles) wrapped in a zinc sulfide shell. Orange and green light is emitted anytime electronics bump into these quantum dots. Lastly, a cathode layer created from EGaln (eutectic gallium indium) sits at the top of the LED and allows the electronics to flow out.

McAlpine iterates that some of these materials are hydrophilic and others are hydrophobic, meaning that this is the largest number of distinct material classes ever 3D-printed into a single object. He hopes that by experimenting with ink formulation and the thickness and uniformity of the quantum dots, that the performance of the printed LEDs can be further improved. The next goal for the Princeton team is to 3D-print fully functional transistors.

Source: Popularscience

Advertisement

Learn more about Electronic Products Magazine