The Fourth Industrial Revolution (Industry 4.0) has triggered a massive influx of computing technologies into industries. This has not only increased the scale of monitored devices and processes but has also exposed the limitations of wired communication technologies. To overcome these limitations, industries are exploring wireless solutions since they are easier to scale and upgrade and cheaper to implement.

This article focuses on the use of software-defined radios (SDRs) as a solution for implementing wireless solutions for industries. It explores various performance characteristics of these platforms and their suitability for implementing wireless industrial internet of things (IIoT) protocols required for Industry 4.0. In addition, the article also explores some of the benefits of implementing industrial IoT solutions using SDR platforms.

Industry 4.0 and wireless IIoT

Industry 4.0 refers to the convergence of various technologies in order to realize intelligent networking of industrial devices and processes. Using wireless networks, data is acquired from connected devices including sensors, actuators, and programmable logic controllers (PLC). This data is processed to enable realization of automated and artificial-intelligence-enabled production and assembly lines. One of the main challenges in achieving this scale of interconnectedness is that most of the devices used in today’s factories utilize dedicated chips and support a limited number of wireless protocols. Figure 1 illustrates the broad scope of Industry 4.0.

Although connectivity in industrial environments has always been dominated by wired communication technologies, many industries are gradually switching to wireless tech. Some of the main factors behind this transition include quicker configuration, higher mobility, and lower installation and maintenance costs of wireless connections. The scale of interconnectedness offered by wireless IIoT provides industries with real-time insights that help to enhance quality control, productivity, and business agility. This large-scale monitoring also helps with forecasting failure of devices and equipment and predictive maintenance, helping to lower costs and decrease unplanned downtime.

Challenges facing Industry 4.0

There are many challenges that are hindering the realization of Industry 4.0. To start with, there exists many non-interoperable wireless technologies in today’s industries. In order to realize industry 4.0, it is necessary for industries to utilize RF devices that can easily adapt to any infrastructure. This level of adaptability also demands devices with minimal and deterministic latency, high interference robustness, and high flexibility.

The complexity of a network increases correspondingly with the number of connected devices. IIoT requires advanced techniques to resolve latency-related issues and to handle resource orchestration. In addition, wireless IIoT poses more network security challenges as compared to wired connections used in today’s industries.

With an increased number of connected devices, IIoT will create hostile RF environments in industries which demands advanced interference monitoring and mitigation technologies. Furthermore, it is difficult to use wireless technologies to connect industries that are located in remote locations such as petrochemical plants and mining rigs because wireless signals are highly susceptible to degradation caused by time varying effects.

Performance characteristics of SDRs

An SDR system utilizes software-based components to perform a broad range of signal processing functions. In contrast, traditional radio systems use dedicated hardware such as modulators, equalizers, and coders to perform such functions. An SDR platform features a radio front-end (RFE) that handles analog signals and a digital backend that processes digital signals. The RFE of a typical SDR system performs receive (Rx) and transmit (Tx) functions and is designed to operate over a broad frequency range.

Highest performance SDR systems offer a high instantaneous bandwidth and multiple independent channels with dedicated analog-to-digital converters (ADCs) and digital-to-analog converters (DACs). The digital backend of a high performance SDR system features a field programmable gate array (FPGA) with a variety of onboard digital signal processing (DSP) capabilities. In addition, these digital backends are optimized to deliver ultra-low and deterministic latency.

Wireless communication in Industry 4.0

Wireless communication technologies are used in industries for a wide range of applications including controlling machines, monitoring machine conditions, as well as the collection and adjustment of production-process values. Some of the wireless technologies used in industries include Zigbee, WirelessHART, and long-range wide-area network modulation (LoRa).

To start with, the Zigbee protocol is an IEEE802.15.4-based standard that allows for the development of low-rate wireless mesh networks. This protocol supports distributed and centralized security models. WirelessHART is a robust standard based on the 802.15.4 protocol and is suitable for a broad array of industrial automation applications. LoRa is a low-cost wireless communication protocol that is optimized for use in remote industries such as offshore drilling rigs and mining plants.

The transmission range of a signal is mainly determined by the transmit power and the sensitivity of a receiver. Whereas longer ranges can be achieved by simply increasing the transmit power, regulations restrict the transmitter’s maximum power. In addition, the cost of components such as low-noise amplifiers and antennas increases with the power rating.

The capability of a radio receiver to differentiate the signal of interest from other signals transmitting in adjacent channels is known as selectivity. The presence of phase noise in an RF system can greatly affect its overall performance. This noise mostly originates from short-term phase fluctuations and reducing it helps to enhance selectivity.

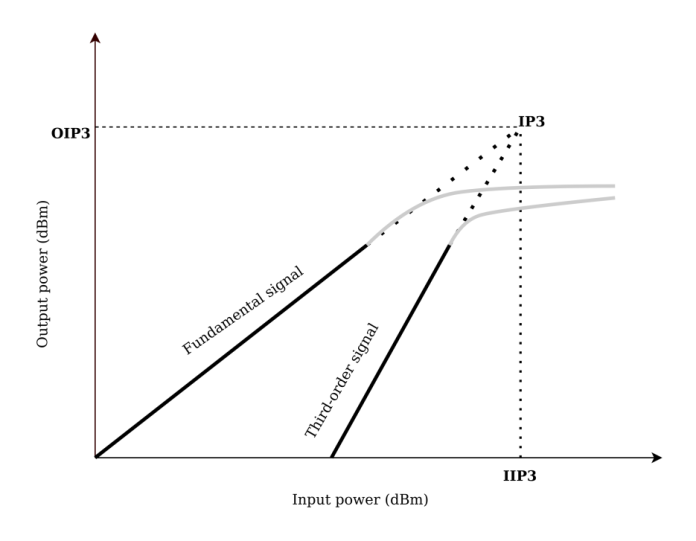

The resilience of an RF system to nearby interferers is greatly determined by the front-end linearity of its receiver. To measure the linearity of a receiver, two tones are inserted into the receive chain and the measurement of the third-order intermodulation product is taken. This product appears at a point corresponding to three times the frequency separation of the two input tones. A high value implies that the receiver is more linear and less susceptible to intermodulation distortion. Figure 2 shows the fundamental signal and the third-order products extended to intersect at the third-order intercept point (IP3).

Figure 2: Fundamental signal and third-order products intersecting at the third-order intercept point (Image: Per Vices)

Addressing issues in Industry 4.0 using SDRs

SDR platforms integrate easily with a broad range of RF communication technologies and can operate across multiple frequency channels. These performance characteristics make them ideal for applications involving real-time data acquisition and transmission. The flexibility of SDR platforms allows data and control links to be adaptively adjusted to meet the conditions of a radio system.

The flexibility of SDR platforms allows each individual wireless link to be customized according to its operating conditions. It also allows a broad variety of digital signal processing techniques such as frequency hopping and modulation techniques to be implemented with ease. In addition, use of software-based components in SDRs helps to shorten the cycle of developing and evaluating new radio protocols used in Industry 4.0.

The performance of an SDR system can be accelerated by offloading compute-intensive tasks to the FPGA. FPGAs have low latency making it possible to implement time-sensitive wireless IoT networks using SDR platforms. Integrating an SDR with a software-defined network (SDN) yields a robust industrial automation system. SDN is a reliable solution for resolving latency-related issues, resource orchestration, and network management. Frequent routing updates are required to combat the high unreliability in IIoT wireless links. With SDN, a network can be dynamically reconfigured based on real-time predefined requirements. In addition, robust solutions for assessing the latency performance of wireless networks can be implemented by utilizing an SDR platform and the IEEE 1588 Precision Time Protocol (PTP).

Applications of SDRs in Industry 4.0

Modern transport systems require high-performance communication solutions that can be used in a broad range of environments such as high-speed systems, remote systems, and more. SDR platforms are suitable for implementing low latency, ultra-reliable communication systems for use in a wide range of fleet management applications.

The architecture of an SDR system allows implementation of physical layers of wireless network protocols required in Industry 4.0. Using an SDR system and GNU Radio, protocols such as WirelessHART can be prototyped quickly and at a low cost. In addition, unlike traditional implementations that are based on dedicated chipsets, SDR-based solutions can be optimized to deliver better latency and reliability performance.

Industry 4.0 demands flexible and scalable solutions that are interoperable with a broad array of RF protocols. The architecture and flexibility of SDR platforms allow RF protocols and DSP algorithms to be implemented quickly and at a low cost thereby making them suitable for use as universal gateways for Industry 4.0 standards.

Most industrial applications have strict latency and reliability requirements that are difficult to meet using existing wireless technologies. One way to overcome this challenge is by replacing traditional solutions that are based on dedicated chipsets with solutions that are based on SDR platforms. SDR-based solutions offer ultra-low and deterministic latency and high reliability. Moreover, SDRs with embedded FPGAs allow for greater flexibility, upgradeability, robustness, reusability, and in general, act as a universal gateway for various Industry 4.0 protocols, compared to dedicated chipsets.

Conclusion

The existence of a wide range of non-interoperable RF standards in today’s industries is hindering the implementation of Industry 4.0. These challenges call for flexible and scalable solutions that can easily integrate with a broad range of technologies. The reconfigurability, low latency, and high performance of SDR systems make them ideal for use in the implementation of wireless solutions for Industry 4.0.

About the authors

Brendon McHugh is a field application engineer and technical writer at Per Vices, which manufactures high performance SDR platforms that are suitable for use in IoT and IIoT applications. Simon Nditru is a technical writer and electrical engineer. Contact solutions@pervices.com for inquiries on SDR solutions.

Advertisement