As PCs and televisions adopt ever slimmer and more elegant form factors, power supplies must achieve lower profiles and adapters for ultra-portable computers must become more compact and lightweight travelling companions.

To help meet targets such as these, quasi-square-wave resonant (QR) power supplies provide high switching efficiency and reduce EMI, which can simplify shielding or suppression. Managing the power supply, a combined flyback and power-factor correction (PFC) controller allows designers to reduce component count. Moreover, by turning off the PFC under low/no-load condition, the controller can improve standby efficiency. The roadmap for this type of device is moving towards further feature integration and enhanced switching performance for lower audible noise.

Combination QR/PFC controllers

A number of combination devices are available, featuring PFC and quasi-resonant flyback control in a single package. High-voltage IC technology allows direct startup from the rectified ac-line voltage. Logic circuitry controls the flyback and PFC switching waveforms as well as functionality such as soft-start and protection features including overcurrent, overvoltage, and overtemperature protection, safe restart and demagnetization detection.

During normal operation, PFC enhances efficiency by minimizing reactive power and preventing distortion of the line-voltage waveform. It is mandatory in appliances rated over 70 W, but is not required at lower power levels, where energy losses in the PFC circuitry can reduce efficiency. To save these losses, some commercial combination flyback/PFC controllers are able to turn the PFC off and hence improve efficiency at light loads and in standby mode.

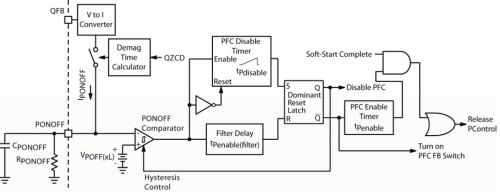

A novel feature of ON Semiconductor’s NCP1937 controller allows the user to program the PFC disable threshold based on the percentage of output power. Internal circuitry generates a current proportional to the output power, which is scaled and averaged using an external resistor and capacitor to produce a voltage proportional to output power. The IC uses this voltage in conjunction with an integrated PFC disable timer and a reference that varies with the line voltage to coordinate turning off and re-enabling the PFC. This allows the PFC stage to be disabled between 25 and 50% of the load at low line and between 50 and 75% at high line. The PFC stage is also disabled during power-up until the flyback soft-start time expires. In addition, the circuitry needed to turn off PFC by opening the feedback connection is integrated in the device. Conventional combination devices require an external feedback connection with a MOSFET circuit to open or close the loop as required. Figure 1 illustrates the PFC on/off control circuitry.

Fig. 1: Integrated circuitry for PFC on/off control.

This feature provides one example of how advances in high-voltage IC technology are allowing manufacturers to deliver more highly integrated controllers that allow power supply designers to eliminate additional external circuitry and further improve efficiency across the load range. ICs with high-voltage capability have typically provided only limited digital capability. More advanced high-voltage processes now allow smaller digital feature sizes, permitting extra on-chip functionality, which enables designers to build smarter and more accurate power supply solutions within smaller form factors than has been possible in the past.

Keys to improvement

ON Semiconductor’s 700-V high-voltage process also allows the controller to integrate most of the circuitry for discharging the X2 input filter capacitor when the ac-line voltage is removed — a feature required by safety agency standards. This saves the PCB space and power consumed by the external resistor network used for X2 capacitor discharge. The NCP1937 controller has two high-voltage startup circuits, and a novel approach is used to reconfigure these to discharge the input filter capacitance upon removal of the ac-line voltage.

Other integrated features made possible by the advanced process technology, saving several external components, include a power-savings mode (PSM) in which the supply current is reduced to below 70 µA. The typical approach taken with conventional flyback control ICs uses an active-off signal to initiate the low-power mode, which requires an additional bias current to pull down the optocoupler on the secondary side and reduces the overall system efficiency. In contrast, the NCP1937 has internal circuitry that eliminates the need for such a bias current, thereby improving system efficiency when no load is present.

The increased digital integration combined with the advanced 700-V high-voltage process also allows more of the circuitry required for protection features, such as fault detection, current sensing, and overpower compensation to be implemented on chip, reducing reliance on external components.

Better user experience

QR operation of the flyback converter is currently popular in laptop power adapters and televisions, mainly by virtue of zero-voltage switching (ZVS), or valley switching, which improves switching efficiency and produces lower electromagnetic interference (EMI) than a hard-switching architecture.

By nature, the QR converter’s switching frequency varies according to input and output load conditions and tends to increase as the output load decreases. In a conventional QR converter, the free-running frequency is typically clamped at 125 kHz, which is below the 150-kHz CISPR-22 EMI starting point. Hence, at light loads, the MOSFET cannot turn on as soon as a valley is detected but must wait 8 µs, causing some valleys to be ignored. However, if the output power is at a level such that the off-time needed for cycle-by-cycle energy balance falls between adjacent valleys, two or three cycles of first-valley switching may be followed by one cycle of second-valley switching. This phenomenon, known as valley jumping, causes large variations in the switching frequency, which are compensated by large changes in the peak current, resulting in audible noise in the transformer.

Skip-cycle or frequency-foldback operation is often used to reduce the switching frequency as the frequency clamp is reached. This is effective in increasing light-load efficiency, but does not prevent valley jumping. Another drawback of this approach is the relatively low minimum switching frequency required, typically around 30 kHz, necessitating a larger transformer.

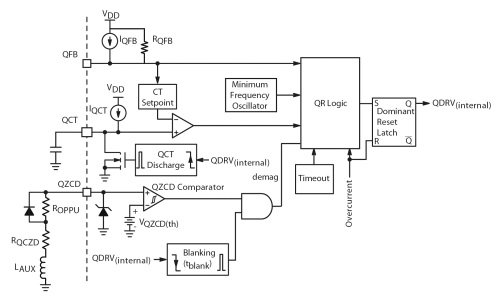

ON Semiconductor’s patented Valley Lockout technique eliminates valley jumping by locking the converter in its selected valley until a significant change in output power is detected. In the NCP1937 this is achieved by using a gang of comparators to monitor the voltage on the feedback pin and feed the information to a counter. The hysteresis on each comparator locks the operating valley. In addition to this, a frequency foldback circuit based on a VCO reduces the switching frequency as the output power decreases, delivering a further improvement in efficiency at light load.

Fig. 2: ON Semiconductor’s valley lockout detection circuitry.

With this innovation, which delivers improved efficiency and a better user experience, combined with increased on-chip integration of features essential for correct operation of flyback/PFC combination controllers, designers can meet the requirements of today’s consumer and business electronics markets.

Demands to continue improving the energy efficiency of high-volume electronic products such as PCs and televisions are coming from many directions, including governments and eco-design bodies. For end users, products that are smaller, slimmer, and lighter are consistent with meeting these requirements as well as their own desires for greater style and mobility. As equipment becomes smarter, maximizing energy efficiency across diverse operating conditions and usage modes, power supplies can also look and act smarter by using the latest power semiconductor innovations.

Advertisement

Learn more about ON Semiconductor