Recent developments in sensors and transducers show increasing emphasis on connectivity for the IoT, intelligence for more integrated, standalone solutions, and higher performance in terms of precision and accuracy.

The applications driving these developments include asset and device tracking and sensing, wearables, automotive, and smartphone applications such as virtual reality and augmented reality. In particular, radar-based ranging and position sensing for automotive has made marked improvements, thanks to a technology shift to the 76- to 81-GHz millimeter-wave bands.

The integrated packaging of sensors is also a key enabler for developers who need to respond quickly to customers’ needs, particularly in consumer applications. Bosch Sensortec GmbH is focused on the consumer arena, and according to Wolfgang Schmitt, senior manager of strategic marketing, end users have an increasing demand for better, more reliable, and more convincing use cases. “That can be influenced generally by sensor performance,” he said, referring specifically to higher precision.

This applies to six-axis inertial measurement units (IMUs) that are being built into smartphones. Also, in fitness trackers, “higher performance of the acceleration sensors and more sophisticated step-counter algorithms directly result in more accurate step-counting figures.”

Two of Bosch Sensortec’s most recent announcements, the BMA456 and BMA423, play directly to this theme, along with the trend toward adding more integrated functionality as well as more standalone processing and control features (Fig. 1 ). Fig. 1: The BMA456 and BMA243 low-power MEMS acceleration sensors from Bosch Sensortec are specifically designed for motion and fitness tracking.Image source: Bosch Sensortec.

Fig. 1: The BMA456 and BMA243 low-power MEMS acceleration sensors from Bosch Sensortec are specifically designed for motion and fitness tracking.Image source: Bosch Sensortec.

The BMA456 and BMA243 include an optimized step counter for wearables integrated directly into the sensor, with no additional external microcontroller required. This helps designers’ cost and power consumption within acceptable limits, reducing design complexity and time-to-market.

Key parameters include 16-bit resolution, a noise figure of 120 µg√Hz, and total offset over its lifetime of only 20 mg. The power consumption for the step-counter function is under 30 µA and the package measures 2 x 2 mm, with a height of 0.65 mm. The sensors can also be used for advanced gesture recognition, such as tilting of the wrist, and can detect activities like running, walking, and standing still.

LoRaWAN and Sigfox compete for best wireless connectivity

As the IoT continues to expand, the connection of sensors through low-power, wide-area networks over ranges of up to 50 km is now possible through LoRaWAN and Sigfox. While range is critical for fast deployment of hundreds or thousands of nodes with minimal concern about easements, low power is just as critical, with a 10-year battery lifespan being the common reference point.

LoRaWAN is supported by the LoRa Alliance, which recently crossed the 500-member point. It operates in unlicensed bands versus Sigfox’s licensed-band operation. It has been held back by limited silicon availability, with Semtech being the only provider of the transceiver and Microchip supplying a module based on that transceiver. However, STMicroelectronics has joined the group and is already producing silicon. Renesas also joined, and it is expected to do likewise.

Even as LoRaWAN ramps up the number of chip suppliers, the two interfaces will continue to offer designers a good connectivity option, as does Narrowband-IoT from cellular operators.

In the meantime, some interesting sensor options have come about, such as the LoRaWAN sensor transceiver from Adeunis RF (Fig. 2 ). Fig. 2: The LoRaWAN sensor transceiver takes any sensor output and converts it to an RF signal for LoRaWAN wireless connectivity. Image source: Adeunis RF.

Fig. 2: The LoRaWAN sensor transceiver takes any sensor output and converts it to an RF signal for LoRaWAN wireless connectivity. Image source: Adeunis RF.

While it’s tempting to integrate more intelligence into each new sensor, including wireless connectivity, that does add cost and space, while also requiring a sensor vendor to commit to one or more interfaces. This can result in multiple SKUs and potential inventory management costs. There’s also the problem of what to do about legacy sensors: How do they get connected to the new wireless networks?

Adeunis RF’s transceiver abstracts the wireless interface from the sensor by taking any sensor I/O signal and converting it to operate over a LoRaWAN wireless network. The I/O can include 0–10 V and 4–20 mA, among others. The result is that both new and legacy sensors — such as those for temperature, pressure, humidity, and CO2 , just to mention a few — can be quickly and easily connected to the IoT over LoRaWAN.

The interface has an RF power of 14 dBm (25 mW), an RF sensitivity of up to –140 dBm, and a range of 10 km. It supports LoRaWAN V1 network protocol.

Automotive radar jumps to wider bandwidth

The recent regulatory required shift from 24 GHz to the 76- to 81-GHz band for automotive radar came with a number of distinct advantages. These advantages include smaller-sized components due to the higher operating frequency, as well as wider bandwidth, the latter of which opens the door to higher-resolution detection.

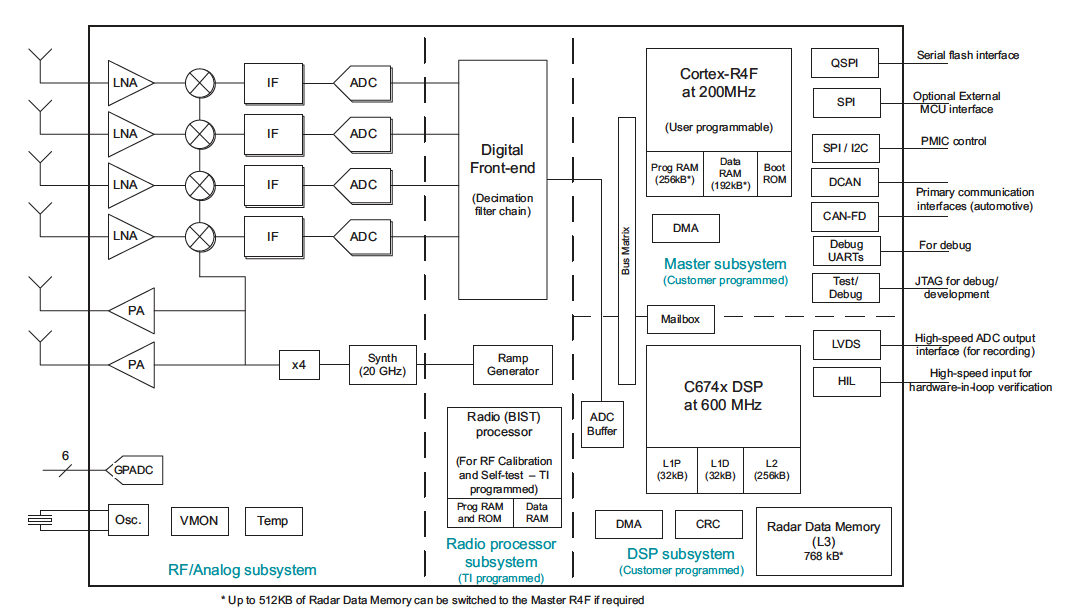

To help designers take advantage of the higher-band operation, Texas Instruments introduced three new radar sensor devices: the AWR1642, AWR1443, and AWR1243 (Fig. 3 ). They vary by level of ARM Cortex-R4 processor and DSP support, as well as the number of transmit and receive channels and their sampling rate (12.5 or 37.5 Msamples/s). All operate in the 76- to 81-GHz band. Fig. 3: The AWR1642 is one of three 76- to 81-GHz corner radar solutions for automotive: It’s more focused on short-range applications than the other two. Image source: Texas Instruments.

Fig. 3: The AWR1642 is one of three 76- to 81-GHz corner radar solutions for automotive: It’s more focused on short-range applications than the other two. Image source: Texas Instruments.

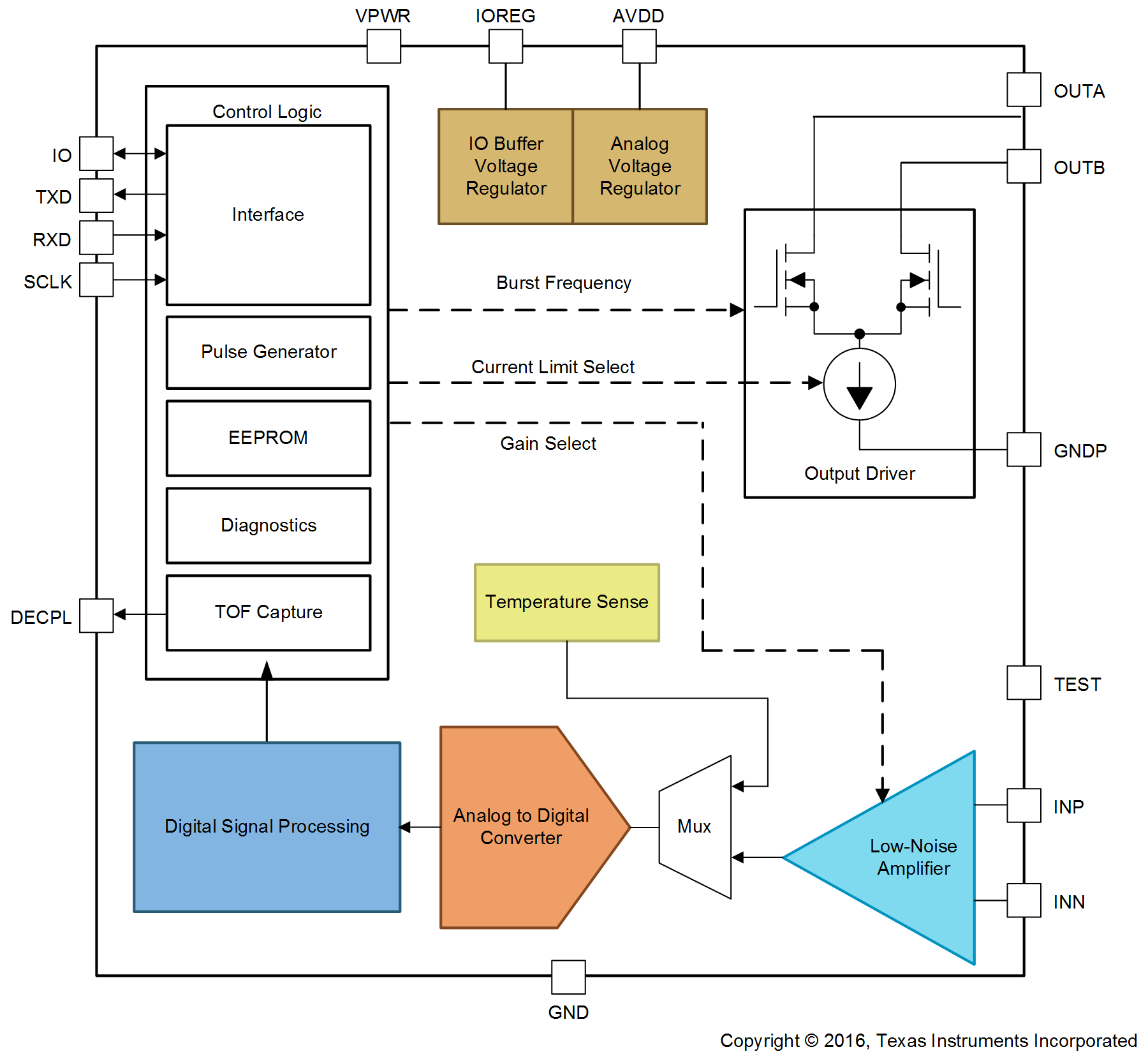

Sticking with automotive, but on the transducer side, TI also introduced the PGA460 ultrasonic SoC with transducer driver and signal conditioner. The chip has a complimentary low-side driver pair that can drive an ultrasonic transducer either in a transformer-based topology using a step-up transformer or in a direct-drive topology using external high-side FETs (Fig. 4 ). It can also receive and condition the reflected echo signal for object detection. Fig. 4: The PGA460 is an AEC-Q100-qualified automotive ultrasonic signal processor and transducer driver.Image source: Texas Instruments.

Fig. 4: The PGA460 is an AEC-Q100-qualified automotive ultrasonic signal processor and transducer driver.Image source: Texas Instruments.

Both radar and ultrasonic signals are being incorporated into semi-autonomous and autonomous vehicles (see Smart vehicles launch the autonomous moonshot). Along with LiDAR, cameras, and even infrared sensors, they are all being recruited into an optimal sensing system for maximum road safety and driving effectiveness.

Haptic-feedback control combines sensors and transducers

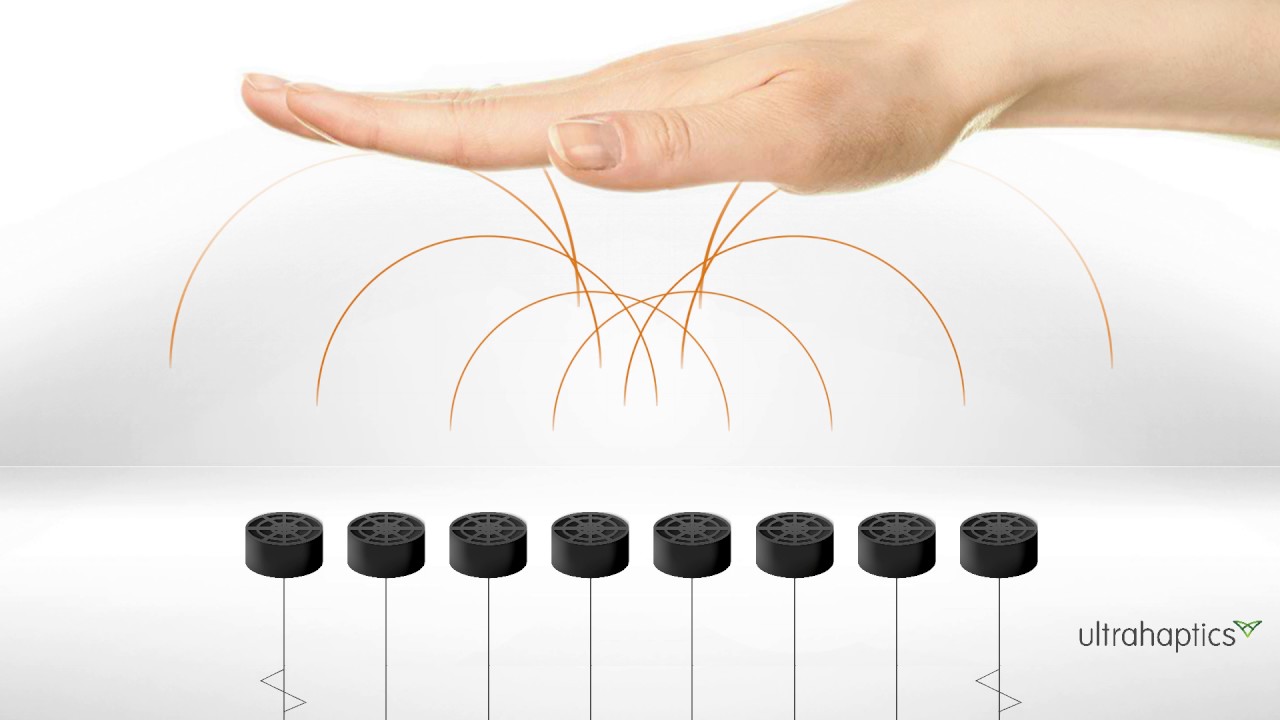

There are many ways to interface with a machine or an automotive dashboard, but Ultrahaptics, a U.K. startup, has developed a means of sensing a hand’s position and then sending precisely targeted ultrasonic pulses to the fingers or hand surface, such that it can feel for all the world like a user is touching a knob or button in mid-air (Fig. 5 ). Fig. 5: Ultrahaptics’ haptic feedback system can use any gesture-sensing technology. Its differentiation is its use of ultrasonic pulses to the hand to provide 3D touch sensations.Image source: Ultrahaptics.

Fig. 5: Ultrahaptics’ haptic feedback system can use any gesture-sensing technology. Its differentiation is its use of ultrasonic pulses to the hand to provide 3D touch sensations.Image source: Ultrahaptics.

Though the technology has been in various stages of development since 2013, it is now gaining traction in automotive and medical applications. These two applications stand out as a designer can use Ultrahaptics’ technology to develop a system that doesn’t require visual coordination, which is distracting for drivers. Nor does it require doctors or others in the medical field to touch surfaces that may be contaminated.

Advertisement