Sensors Expo in Rosemont at the end of June seemed to be a revitalized show — the show floor was crowded, sessions were well attended, and the exhibitors had a lot to talk about. And next year, the show will leave Rosemont, IL, and rotate to the West Coast; the 30th annual conference/exposition will be taking place on June 9 to 11, 2015 in Long Beach, CA at the Long Beach Convention Center. If this year is any indication, that show should be even more successful than this year’s.

Key developments

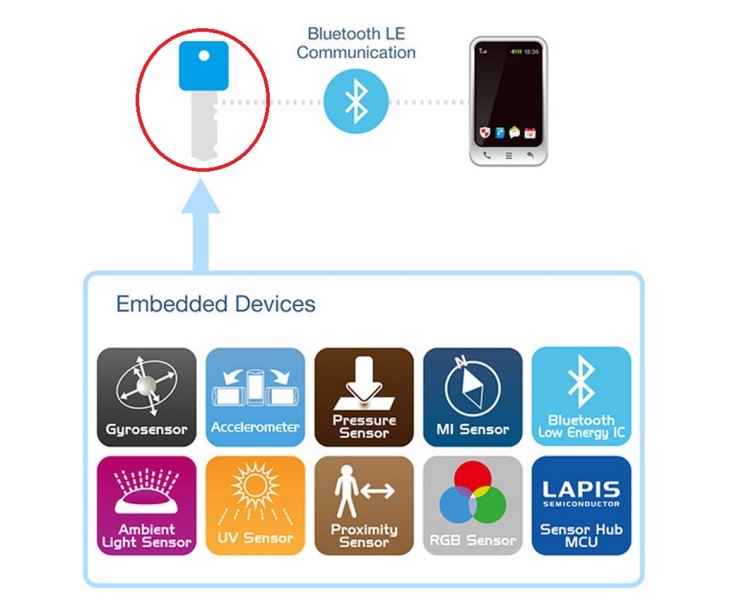

A prime example of the exciting new sensor-based products at the show was the Wearable Key Device application demonstrated by Rohm/Kionix (www.rohm.com). Nominated for the Best of Sensors Expo 2014 Application Award, the demo device is designed to transmit data from multiple sensors to smartphones and tablets using the new Bluetooth Low Energy specification.

The design integrates an ultra-high sensitivity magnetic-impedance (MI) sensor, accelerometer, gyroscope, barometric pressure sensor, proximity /ambient light sensor (ALS), and RGB/UV sensors in a compact, lightweight key-shaped enclosure (see fig. 1 ). The sensor complement makes possible a variety of functions and operations .

Fig.1: The Rohm/Kionix Wearable Key Device demonstrates how a variety of sensors can deliver new funtions that will be attractive to users.

For instance, it can serve as an activity monitor, not only estimating calories burned and counting steps taken, but even detecting when the wearer is riding in a vehicle (i.e. bus, train, car) or walking up/down stairs, and track time traveled. It can also be used as a gesturing device, locking and unlocking compatible tablets and smartphones by holding the key and simply drawing a ‘U' or ‘L' in the air.

Two of the key’s more unusual capabilities are UV and distance measurement. In the former case, wearing the key externally will let a user determine how much UV radiation they are receiving, and alert them if there’s a danger of sunburn or risk of melanoma. The distance-measurement capability relies on having a database of tall landmarks, such as the Empire State Building and the Seattle Space needle; then the user can point to the top of the landmark and the key will indicate the walking distance to it.

Face recognition

Another interesting demo was that of the Human Vision Components (HVC) sensor at the Omron (http://www.omron.com) booth. Delivered on a credit-card-sized board (see fig. 2 ), the HVC sensor is said to offer best-in-class facial detection technology on a self-contained device that is easy to use. To do so, the HVC sensor incorporates Omron’s unique image recognition algorithm (OKAO), giving it the ability to detect faces with very high speed and accuracy. Thus the sensor lets designers add intelligence and functionality to many applications and products with minimal effort.

Fig. 2: The HVC sensor from Omron make it easy for designer to develop face-recognition/human interaction applications.

The HVC sensor is capable of face detection and recognition (using a database), age and gender estimation, gaze estimation (in what direction is the subject looking), expression estimation (happy, sad, angry, and so forth), facial pose (full-on, three-quarter, profile), and blink detection. The sensor can detect faces of various sizes quickly and accurately. Further, it can also detect a hand or body.

Motor efficiency

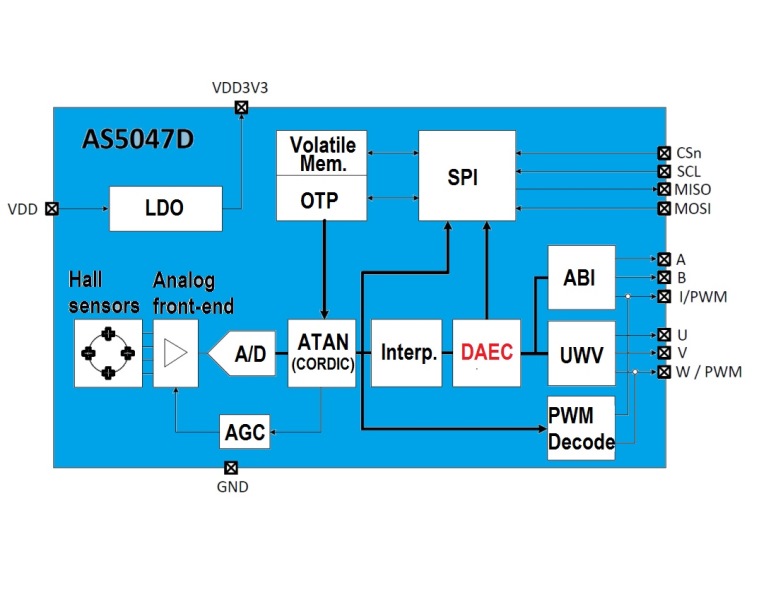

Claiming their new products offered the world’s best accuracy at high rotation speeds, ams AG (www.ams.com) introduced the 47 Series magnetic position sensors. The performance, they said, was due to a breakthrough, patent-pending technology — Dynamic Angle-Error Compensation (DAEC) — capable of producing extremely accurate angle measurements of rotors spinning at high speeds. The series is specified with a maximum angle error of ±0.17° (excluding integral non-linearity), which is about an order of magnitude better than previous devices. The key is that the algorithm is embedded in the device hardware (see fig. 3 ), which also frees users from having to create software that still results in a less-accurate device.

Fig. 3: The AS5047D magnetic position sensor is designed to provide highly accurate dc motor control for such things as robots and consumer goods., thanks to its embedded Dynamic Angle-Error Compensation (DAEC).

Having a more precise determination of angle results in more efficient dc motor operation, which in turn leads to energy savings. The company is targeting different areas of dc motor use with three different versions of the sensor. The AS5047D is isuited for industrial applications including robots and encoder modules, theAS5147 is an AEC-Q100 qualified part for automotive applications such as electronic power steering and pumps, and the dual-die AS5247 (also AEC-Q100 qualified) is aimed at automotive applications requiring the highest level of functional safety compliance. The 47 Series devices offer high 14-bit resolution (to 0.022°) in their digital SPI output; maximum resolution is 2,000 steps per revolution in decimal mode and 2,048 steps per revolution in binary ABI mode. Pricing in 1,000 piece quantities begins at under $5.

Bluetooth and sensors

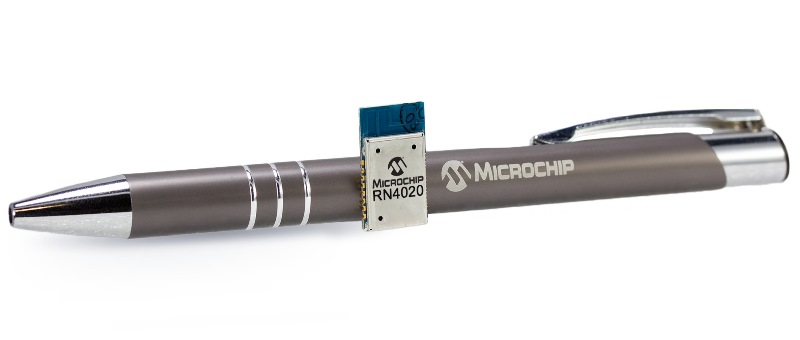

Furthering sensor system communication, Microchip Technology announced its first Bluetooth 4.1 Low Energy module, with integrated Bluetooth Low Energy (BTLE) stack and onboard support for the common Bluetooth Special Interest Group (BSIG) low-energy profiles. The fully certified (BSIG and more) RN4020 module aims to speed time to market while ensuring Bluetooth compatibility, eliminating expensive certification costs, and reducing development risks.

Fig.4: The tiny, low-energy RN4020 from Microchip Technology can be used with sensor by itself, without a microprocessor, to provide Bluetooth communication for a host of new applications.

The tiny module (see fig. 4) is also pre-loaded with the Microchip Low-energy Data Profile (MLDP), which lets designers stream any type of data across the BTLE link easily. Because the RN4020 is a stack-on-board module, it can connect to any microcontroller with a UART interface.

What’s more, the module can operate standalone — that is, without an MCU — for basic data collection and communication, such as a beacon or sensor. Standalone operation is facilitated by Microchip’s no-compile scripting, which allows module configuration via a simple ASCII command interface—no tools or compiling are required.

With a compact form factor of only 11.5 x 19.5 x 2.5 mm, the RN4020 also provides a built-in PCB antenna with 7 dBm transmit power and a receive sensitivity of -92.5 dBm, which, depending on environment, enables operation over 100 meters. The RN4020 Bluetooth Low Energy Module is available for $6.78 each in 1,000-unit quantities.

Safe and power-smart

Microchip also announced the expansion of its eXtreme Low Power (XLP) PIC microcontrollers offerings with the PIC24F “GB2” series that features integrated hardware crypto engines, random-number generators and one-time-programmable (OTP) key storage for protecting data in embedded applications. The series’ devices, which offer up to 128 KB Flash and 8 KB RAM in 28- or 44-pin packages, are aimed at Internet of Things (IoT) battery-operated or portable devices for applications such as medical/fitness (pedometers, wearable fitness, handheld devices), computing (PC peripherals, printers, portable accessories), and industrial (security door locks, access control systems, security cameras, POS terminals, smart card readers, heat/gas meters, IoT sensor nodes).

The series’ hardware crypto engine — which reduces software overhead, lowers power consumption, enables faster throughput, and supports the AES, DES and 3DES standards— is an example of Microchip’s Core Independent Peripherals, which can run with no CPU supervision. The RNG creates random keys for data encryption, decryption, and authentication, and, for additional protection, the OTP key storage prevents the encryption key from being read or overwritten. All these features increase the integrity of embedded data without sacrificing power consumption; the GB2 family has 180-µA/MHz run currents and 18-nA sleep currents.

The microcontrollers integrate USB for device/host connections and a UART with ISO7816 support for smartcard applications, and can work with a range of certified wireless modules for Wi-Fi, ZigBee, Bluetooth, and Bluetooth Low Energy. The family is supported by Microchip’s standard suite of development tools and is available now in sample and volume quantities, starting at $1.30 each in volume.

Navigation in a little box

At the show, VectorNav Technologies (www.vectornav.com) demonstrated its VN-300 module: a dual-antenna, GPS-aided inertial navigation system (GPS/INS) announced the previous month. The device (see fig. 5 ) is said to have the lowest size, weight, and power requirements of any dual antenna GPS/INS currently available on the market. Intended for industrial and military use, the module suits such applications as robotics, unmanned vehicle systems, antenna-camera-platform stabilization, heavy machinery monitoring, and primary or secondary flight navigation.

Fig. 5: The VN-300 module’s advanced capabilities can simplify the integration of inertial navigation into a variety of industrial and military applications.

The MEMS-based device combines 3-axis accelerometers, 3-axis gyros, 3-axis magnetometers, a barometric pressure sensor, two GPS receivers, as well as a low-power microprocessor in a rugged, 45 x 44 x 11-mm aluminum enclosure. Coupling the GPS compass with the INS capabilities enables applications that require high-accuracy position, velocity, and attitude measurements under both static and dynamic operating conditions. On-board algorithms let applications transition seamlessly between static and dynamic operations, without having to collect extended stationary measurements or perform specific dynamic maneuvers in flight for attitude alignment. Development kits are priced around $5,000, and units are competitively priced with other MEMS-based GPS/INS systems that do not provide dual-antenna, moving baseline real-time-kinematic (RTK) features.

Advertisement

Learn more about Electronic Products Magazine