By Gina Roos, Editor-in-Chief, Electronic Products

Miniaturization is the biggest driver behind the adoption of integrated passive devices (IPDs), which can replace discrete capacitors, resistors, and inductors, in a variety of end products, particularly ever-shrinking consumer devices such as smartphones. They come in a variety of flavors — on silicon, glass, ceramic, and even gallium arsenide (GaAs). Silicon-based IPDs have been making big inroads thanks to the inherent advantages of wafer processes, including repeatability and tight tolerance control, and is still the substrate material of choice for IPDs.

The IPD market is growing at a fast clip and is forecast to reach $1.5 billion in 2023, up from $1.0 billion in 2018, growing at a compound annual growth rate of 8.8%, according to a new report released by MarketsandMarkets. In particular, thin-film or silicon-based IPDs have been making inroads thanks to their higher performance in the areas of pitch, tolerance, flexibility, and packages, according to Yole Développement (Yole), which expects the IPD market to surpass $1 billion by 2022.

The key applications for IPDs have been electrostatic discharge (ESD) and electromagnetic interference (EMI), which have well-established standards. However, the integration of IPDs for RF front-end modules that use baluns, diplexers, and filters is gaining ground, targeting portable, wireless, and RF applications. There are more than a handful of players in the RF IPD market that offer standard or custom devices. These include Murata IPDia, ON Semiconductor, STMicroelectronics, and Qorvo.

RF IPD benefits

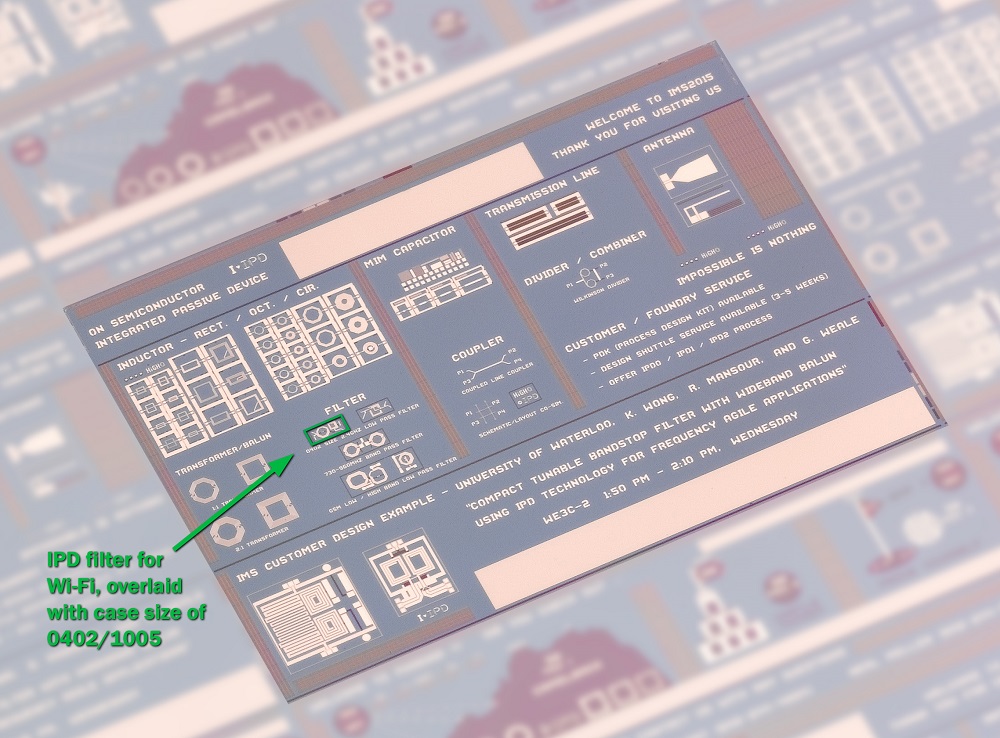

IPD technology can be used in a variety of RF designs — including baluns, couplers, diplexers, filters, splitters, and matching networks — combining capacitors, resistors, and inductors in a single package. The biggest demand drivers are size, tolerance, and performance, said Kim Eilert, principal engineer and IPD product line manager at ON Semiconductor.

ON Semiconductor builds custom RF IPDs on its silicon-based High-Q copper platform. Part of Eilert’s job is to help customers design IPDs and make sure that they are successful with the product, which is why she’ll tell you that RF IPDs aren’t recommended for frequencies at

However, there are some applications in which it is made to order, she added. These include applications that call for miniaturization, tight tolerance, and higher performance.

Eilert said that when design engineers begin their design for a system, they often consider multiple technologies and they are looking at things like cost, size, thermal performance, and ease of assembly. They will consider several technologies and evaluate what they need.

“When folks decide to use IPDs — be it on glass, ceramic, silicon, or GaAs — in general, they are being driven by the profile height and the x- and y-size,” she added. “Being able to thin down an IPD to match the exact height of your active ICs is an advantage because you can shrink the z-height of your overall module.”

IPDs are much smaller than discrete solutions, and the x-/y-size savings can be huge. “By adding integration, you’re able to shrink the x/y footprint required by the components,” said Eilert. “Sometimes it’s not just a ‘nice-to-have,’ it’s an absolute requirement.”

Another factor driving IPD design-ins is tolerance. “If you are buying each component of your filter separately, they all have individual tolerances, so the overall system has a wider tolerance then if you fabricated it as a separate chip.”

“Because we’re making everything at the same time on this [IPD] chip, all of the capacitors on that single chip, for example, will be well-matched with each other. So there is a performance advantage. There is also a performance advantage at higher frequencies — again, due to it all being fabricated on a wafer with good [submicron] dimensional control.”

Parasitics is another challenge for designers. “Sometimes at higher frequencies, the undesirable parasitics of mounting components can really disrupt the performance of the design,” said Eilert. “When you have everything integrated into one chip, you no longer have the mounting parasitics to contend with.”

Eilert’s advice is to always request an example chip. In the case of inductors, Q or high-quality factor is often cited as a key metric. Get an example chip and measure it for yourself, she advises. “Oftentimes, foundries have this information and can provide it, but designers need to request raw data when they make these comparisons.”

She also asks designers to consider the overall resonator Q instead of looking at individual components and comparing inductors to inductors and capacitors to capacitors.

“When we design resonators — and most of the time, that is what filter designers do — an IPD is great because you can have an inductor (L) right next to a capacitor (C) integrated together,” she said. “With other technologies, there may be a restriction on how close you can get the two components. I recommend that they compare the overall system — compare the LC resonator to the LC resonator. Ultimately, that is what they are trying to build.”

Like most things, there are trade-offs with custom IPDs. Time to market and cost are two of the biggest.

“I think people prefer not to engage in a separate design effort if they can avoid it,” said Eilert. “There are advantages to using components off-the-shelf — they are readily available, the devices are very familiar, and, from a cost perspective, it requires less time and resources compared to developing a custom chip. So there needs to be size drivers or performance drivers to lead people into doing IPD.”

Big opportunities where performance is needed

Thanks to the repeatability and sub-micron tolerances — an advantage at high frequencies — of wafer processes, most of the commercial frequencies (about 1 GHz to 6 GHz) are a good fit for silicon IPDs.

A lot of customers are using RF IPDs in the 1-GHz to 2.5-GHz range, said Eilert. IPDs will also be well-suited for 5G, which will be going up to 28 GHz — and that is challenging to the designer.

“For example, if you have to design a bandpass filter at 20 GHz, building it on a wafer technology where you have very precise control of the dimensions is advantageous,” she said. “Since this is a wafer process, we’re using lithography to define the traces. You can have a 5-micron-wide trace and everything comes with sub-micron tolerances.”

The mechanical properties of the silicon are also a benefit. “For some applications, it is desirable to have the mechanical expansion properties of the ICs match with the carrier package,” said Eilert. With silicon IPDs, the carrier package will be made of silicon and the active ICs are made of silicon, so there is no mechanical mismatch, she added.

Designers can also use IPDs when they need an exact capacitor or inductor value. “You can buy off-the-shelf components, but they come in a fixed-value range,” said Eilert. “If you want a 4.7-pF capacitance, you can buy it right now in a variety of form factors, but if you want something highly customized like 4.85 pF and need a tight tolerance, then an IPD is the way to get you there.”

ON Semiconductor offers example chips and full-featured design kits to help jumpstart projects and to show customers what is achievable with the technology.

Designers rarely stick with the baseline design, said Eilert. “What we find is that people don’t want to buy from a catalog; they want to customize for their application. That is true, in general, for RF, where you start with an example and then you customize the pinouts or you customize the performance or the impedance to match your specific IC. There is a performance advantage to it, but it does take design effort.”

There are a wide range of things that designers can do with IPDs. Eilert said that she’s even had a customer build an IPD with only one component on them to get an exact inductance value, and another customer used the entire 8-inch silicon wafer for one chip as a type of interposer.

However, ON Semiconductor has several design examples in which the IPDs saved significant space. In one case, the company built a low-cost and low-insertion-loss bandpass filter for the new 5G New Radio n78 band, housed in a 1608 package (1.6 x 0.8 mm) that integrates 20 components.

However, there are other semiconductor manufacturers that offer off-the-shelf RF IPDs. For example, STMicroelectronics offers a family of integrated baluns built on its IPD on non-conductive glass-substrate technology. These are highly integrated matching devices that offer low signal losses with low amplitude and phase imbalances thanks to the IPD technology.

As of the end of 2017, ST offered 16 integrated baluns in package sizes down to 0.8 mm2 and 0.56 mm high after reflow. These devices are designed for ST’s sub-1-GHz or Bluetooth Low Energy 2.4-GHz radios, as well as a variety of transceivers from other manufacturers.

One of ST’s most recent IPD launches is a matched balun for its S2-LP 868-927MHz low-power radio transceiver, aimed at saving board space in products such as IoT sensors, smart meters, alarms, remotes, building automation, and industrial controls.

ST said that the 3.26-mm2 BALF-SPI2-01D3 integrates all of the impedance-matching and filtering components needed to connect an antenna to the S2-LP radio. The integrated device replaces a conventional network of 16 discrete capacitors and inductors that can occupy up to 100 mm2 of board real estate, translating into a footprint reduction of more than 96%.

“In addition to saving space, circuit design is greatly simplified, with no need to select component values or tackle exacting layout challenges,” said ST. “Fully optimized for the S2-LP, the balun comes with placement and connection recommendations that are tested and verified and can be directly replicated to maximize RF performance.”

As products continue to shrink, demand for all types of IPDs are expected to grow.

“With size drivers in the market, especially with smartphones, there is pressure to reduce size; it’s not optional,” said Eilert. “With conventional solutions, they are too large for next-generation products.”

Advertisement

Learn more about Electronic Products Magazine