Researchers at MIT have developed a new approach to generating power from sunlight that is not only efficient, but also capable of delivering power on demand, even if there is no sunlight. The energy-harvesting approach uses sunlight to heat a high-temperature material, whose IR radiation is then collected by a conventional photovoltaic cell. By adding an extra conversion step, thermophotovoltaic (TPV) devices can improve performance because they can take advantage of wavelengths of light that ordinarily go to waste with traditional PV devices. The process is described in a paper recently published in the journal Nature Nanotechnology , written by graduate student Andrej Lenert, associate professor of mechanical engineering Evelyn Wang, physics professor Marin Soljačić, principal research scientist Ivan Celanović, and three others.

A conventional silicon-based solar cell “doesn’t take advantage of all the photons,” Wang explains. That’s because converting the energy of a photon into electricity requires that the photon’s energy level match the bandgap of the silicon used to make the photovoltaic (PV). While silicon’s bandgap responds to many wavelengths of light, it misses many others.

To address silicon’s limitation, the team inserted a two-layer absorber-emitter device between the sunlight and the PV cell. Their nanophotonic solar TPV device is composed of an array of multiwalled carbon nanotubes as the absorber, a one-dimensional silicon/silicon dioxide photonic crystal as the emitter, and a 0.55-eV photovoltaic cell. By collecting energy from a broad spectrum of sunlight, the intermediate material is heated and emits light of a particular wavelength that is tuned to match the bandgap of the PV cell.

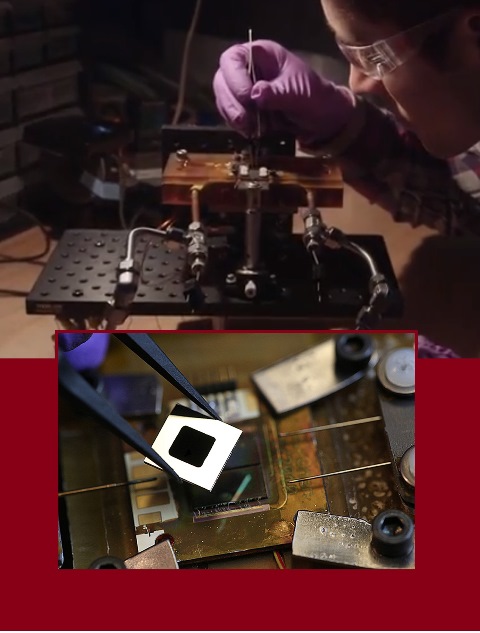

MIT graduate student Andrej Lenert makes some adjustments to a nanophotonic solar thermophotovoltaic device, shown in greater detail below. The tweezers hold a “sandwich” of a multiwalled carbon nanotube array as the absorber and a one‑dimensional, silicon/silicon-dioxide photonic crystal as the emitter. It is being positioned over a 0.55 eV photovoltaic cell which does the final energy conversion.

(Top photo: from a video courtesy of MITMECHE; Bottom photo: John Freidah.)

Such solar thermophotovoltaic (TPV) systems circumvent the Shockley-Queisser limit on energy-conversion efficiency of semiconductor-based photovoltaic devices. The S-Q limit imposes a cap of 33.7% on such efficiency, but Wang says that with TPV systems, “the efficiency would be significantly higher — it could ideally be over 80%.” Lenert, Wang, and their team have already produced an initial test device with a measured efficiency of 3.2%, and they say with further work they expect to be able to reach 20% efficiency — enough, they say, for a commercially viable product.

The design of the two-layer absorber-emitter material is key to this improvement. The array of multiwalled carbon nanotubes facing the sunlight turns light to heat very efficiently. This layer is bonded tightly to a photonic crystal layer that, when heated by the attached nanotubes layer, “glows” with light whose peak intensity is mostly above the bandgap of the adjacent PV. This ensures that most of the collected energy is then turned into electricity.

The researchers found that peak efficiency came at what is equivalent to concentrating sunlight by a factor of 750, using a focusing system. This level of concentration is already much lower than in previous attempts at STPV systems, which concentrated sunlight by a factor of several thousand. But the MIT researchers say that after further optimization, it should be possible to get the same kind of enhancement at even lower sunlight concentrations, making the systems easier to operate.

Some of the ways to further improve the system are quite straightforward. Since the intermediate stage of the system, the absorber-emitter, relies on high temperatures, its size is crucial: The larger an object, the smaller the surface area and the less heat loss. Initial tests were done on a 1-cm chip, but follow-up tests will be done with a 10-cm chip.

The research team also included MIT graduate students David Bierman and Walker Chan, former postdoc Youngsuk Nam, and research scientist Ivan Celanović. The work was funded by the U.S. Department of Energy through MIT’s Solid-State Solar Thermal Energy Conversion (S3TEC) Center, as well as the Martin Family Society, the MIT Energy Initiative, and the National Science Foundation. For further invormation, contact Evelyn Wang at .

Advertisement

Learn more about Massachusetts Institute of Tec