By RUSSELL CRANE, Audio Marketing Manager

and MATTHEW KUCIC, Audio Systems Engineer

Texas Instruments

www.ti.com

Remember the days when you strung two tin cans together to make a telephone? Unfortunately, cell phone audio can sound a lot like those tin cans because of the miniaturization of devices, including the speakers. Unless you have upgraded your phone to a top-of-the-line handset over the last couple of years, you know that using your loudspeaker for either voice or audio can be, well, painful. That's because handset manufacturers have been slow to make audio a differentiator in high-end handsets, and there is little low-frequency audio, commonly referred to as bass, present.

This is now changing thanks to a technology that we call smart amplifiers, or smart amps, because, unlike traditional amplifiers, they can safely and temporarily push the speaker to its limit. By sensing a speaker’s operation while playing music and applying advanced algorithms, smart amps can get a lot of sound out of a cell phone’s micro-speaker without hurting your ears.

What is in a speaker today?

Before we discuss how smart amps work, it is important to understand another key piece of the audio signal chain: the speaker. Regardless of the amplifier, if the speaker isn’t designed properly, no amount of audio processing or amplification will overcome its shortcomings. It would be like putting rocket-fuel in a lawnmower engine — all of that power and no way to use it. However, if you start with a reasonable engine, adding a smart amp is like adding a turbo charger to push it to the limits in a controlled manner.

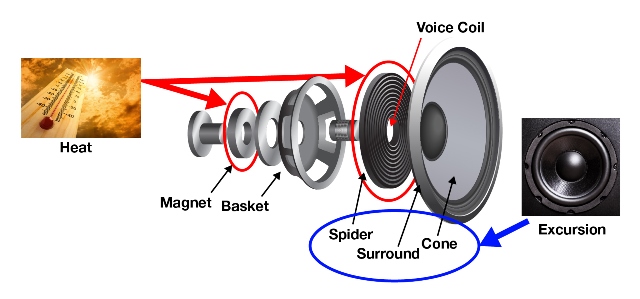

Speakers are constructed with a frame, magnet, voice coil, and diaphragm (Fig. 1 ). Electrical current moves through the voice coil, which causes it to magnetize by reacting with the speaker's fixed magnet. This motor causes the membrane attached to the coil to move up and down and emanate sound waves that are actually audible. We call the movement of the diaphragm excursion, and this excursion has limits. When the excursion limits are exceeded, audible distortion can occur. In extreme cases, a damaged speaker may result in failure. Traditional amplifiers use simple equalization (EQ) to limit the excursion. However, to protect across all speaker variations, operating conditions and audio signals, these filters are generally conservative — giving up the ability to push the speaker to its true limit.

Fig. 1: Anatomy of a speaker.

A second problem with speakers is that, as current is pushed through the voice coil, some of the energy is converted into heat instead of sound. Push the speaker too hard and this heating can possibly damage the voice coil by melting the varnish on the magnetic wire. As the voice coil heats from the energy delivered by the amplifier, it must cool through the magnet into the surrounding structures. In traditional amplifiers, the maximum power is limited to a value that, if continually supplied, will not damage the speaker. This maximum power value must cover all speaker variations, operating conditions and signals. As such, this value is typically below what the speaker can handle and is, therefore, conservative.

What makes an amp smart?

How can we extract the most sound pressure level (SPL) from a given speaker and still ensure safe operation? We can use a smart amp. Audio has a peak-to-average ratio (PAR) that allows us to push the instant peaks while maintaining average or safe levels. Smart amps fall into two categories. The first is feed-forward, in which models of the speaker are created and the audio is fed through these models to predict the speaker’s behavior. Feed-forward tends to work well for larger speakers in which the variations are smaller and the operation is more linear. Even with larger speakers, we must account for the speaker variations in the headroom, but the dynamic system can temporarily push the speakers to the limits to produce loud audio.

Micro-speakers, commonly used in smartphones, require a slightly more advanced smart amp. The second category is feedback smart amps, which add current and voltage (IV) sense to the digital-to-analog converter (DAC) and Class-D of the feed-forward solution. This IV-sense allows us to directly measure the speaker's voice coil temperature and detect changes in the speaker due to unit-to-unit variations, ambient temperature, and loading of the speaker (such as placing your hand over the speaker port). This information allows the algorithm to extract additional SPL from the speaker that otherwise would be lost by limiting the output to cover these variations.

To take advantage of the voltage and current sense information, smart amps need a processor (preferably a digital signal processor, or DSP) to parse this data and apply sophisticated algorithms to extract the best performance and sound while maintaining safe speaker operating conditions. Smart amps with or without integrated DSPs are available to meet the designer’s cost, time-to-market, and performance expectations.

Getting to know your speaker

With a basic understanding of how speakers and smart amps work together to deliver better sound at higher volumes, we can discuss how to get your product to market using this technology. The first step is to create a speaker characterization that measures numerous aspects of the speaker to identify its limits. These limits must be fully understood to get the loudest and highest-quality sound from the speaker without damaging it. Take detailed measurements to develop an accurate model of the speaker. One way to do this is with TI’s PurePath Console 3 (PPC3) along with a companion learning board; the combination can perform these measurements using an easy-to-follow procedure.

These measurements include, but are not limited to, system checks, excursion characterization, thermal characterization, and SPL measurements. Although the excursion measurement can be done using parameters from the speaker data sheet, a more accurate method is to use a laser displacement sensor to measure excursion and extract the needed parameters. TI’s smart amp learning board allows engineers to easily characterize speakers by providing all the data acquisition needed using the laser, as well as a microphone for SPL measurements. Once complete, users can quickly view the different measured data plots, including excursion versus frequency and safe operating area limits.

TI’s PPC3 can simplify the tuning process. Its suite of sophisticated tools automatically merges the low-end impedance measurements with high-frequency microphone measurements. This creates a clean, full-frequency SPL measurement to begin the tuning. The low-frequency bass region can quickly be tuned to push the bass by easily selecting various alignment filters and allowing the software to automatically generate the needed compensation filters. The smart amp dynamically adjusts this filter to push the maximum bass without exceeding excursion limits. Next, the speakers voicing can be easily performed using SmartEQ. The user can simply specify the target EQ curve and PPC3 will calculate the necessary filters to adjust the speakers measured SPL response to the target EQ. The tool does all the math, allowing the acoustic engineer to quickly obtain the results without the restrictions normally found in the competing EQ solutions.

Putting it all together

With speaker characterization and fine-tuning complete, it is important to ensure that your selections can operate safely and reliably across a larger sample of speakers. This reliability testing is an important step before taking your product to the assembly line. Invariably and regardless of speaker manufacturer, there is variance from speaker to speaker. Although the tuning sounds good and it appears to be within safe operating limits, additional speakers may not be as robust as the target you have been working on through the previous steps. It is recommended that you take a larger sample of your speakers through a lifetime test. This sample should be at least 20 speakers, which you should test over a longer time and across extreme temperatures to simulate your expected customer use-cases. Use the test results to adjust your final safe operating area parameters.

If you are using the TI TAS2555 smart amp, you do not need to integrate the smart amp sequencing and settings into the host processor, because a DSP is fully integrated into the smart amp. This greatly reduces software development time. Further, if your application processor is upgraded or changed, there is no need to re-integrate sequencing and settings.

As you move to the production line, a fast-and-robust test program can be implemented to ensure that the end product adheres to the parameters set during development. Production-line software can help screen the speakers, making sure they are within preset limits and were not damaged during assembly. Additionally, speaker-to-speaker impedance variations can be measured and stored. This step ensures that the full thermal headroom of each speaker can be used.

References

1. Visit TI’s Smart Amp page for more information about TI smart amps.

2. Visit TI’s E2E Community Audio Amplifier Forum, where engineers ask questions and help each other solve problems.

Advertisement

Learn more about Texas Instruments