Assemble a team of rugged hotshots, design an eye-popping vehicle, attempt to fly it off a ramp, and miserably crash into a body of water; if you’re thinking I’ve just described the basis of solar car racing then you’re sadly mistaken. Unlike Red Bull’s Flugtag competition, solar car racing forces competitors to think critically about designing an energy-efficient vehicle capable of traversing hundreds of miles, at highway speeds, on less than the power of a hairdryer. Kat Han, co-founder of Oregon State University’s Solar Vehicle Team (OSUSVT), tells us that the races challenge young engineers to design vehicles that balance efficiency, structural integrity, and reliability.

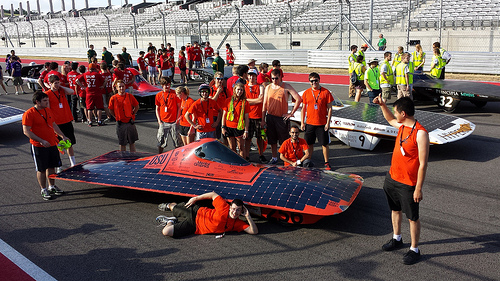

When Han talks about solar racing, you listen. Just recently, her team took 1st place in the 2013 Formula Sun Grand Prix ― having completed 193 laps in three days. The FSGP takes place within the Circuit of Americas in Austin TX, and the OSU team’s vehicle, called Phoenix, covered 661 miles exclusively on solar power.

Han herself is an interesting figure: a botanist with a master’s degree in plant genetics, she initially dabbled in solar car racing for the hell of it. Seven years and three cars later, she now pursues a Ph.D. in chemical engineering courtesy of transforming her hobby into a career.

Race regulations

Solar car race regulations are very specific, placing severe energy constraints on vehicles. For example, the FSGP’s 2013 regulations state that vehicle propulsion must be exclusively powered by the solar radiation captured from solar arrays as well as any energy recovered from motion. The only exception to this rule is that vehicles are permitted to use energy stored in the battery system at the beginning of the first day.

According to Kat, the biggest challenge her team faced was adhering to a maximum of six square-meter solar arrays. However, she stressed that ingenuity is what ultimately helped the OSU team maximize power absorption from such limited surface area, “our team managed to purchase bare solar cells and solder and laminate our own array, and the students did a very good job producing those modules.”

Experimenting, lateral thinking, and learning from mistakes are what drive the creative forces behind solar car design. Kat muses that an additional module design change should’ve been implemented alongside the new type of solar cell to extort even more power; because of its absence the team was forced to heavily budget power consumption. Ultimately, electrical system management is but one of the factors affecting overall race performance as we learn from Kat: “A combination of great driving from our four drivers, efficient aerodynamics, good organization during solar charging times, and careful strategy for speeds during the race allowed us to complete the most laps.“

Solar car capabilities

Phoenix is one tough mother ― the vehicle’ wears the salvageable remains of its predecessor destroyed in a 2011 fire. The name is indicative of OSUSVT’s continued dedication and optimism, feelings which have yielded a 1st-place-winning vehicle that's able to fly down Oregonian highways at up to 65 mph.

Phoenix is actually capable of reaching 85 mph although never legally tested.

When questioned about the uniqueness of their design, Han informs us that her team had two primary advantages over their competitors, “First, we arrived with a reliable, previously tested vehicle. Second, we are using a battery technology that is safe and efficient.” Phoenix’s battery is lithium iron nano-phosphate, enabling high charging and discharging efficiencies. This permitted the vehicle to continue racing while the other teams’ batteries were overheating and shutting off.

Phoenix was a rather reliable vehicle, suffering only two popped tires, one brake scraping, and one motor problem during the race. The only real culprit was the motor which Kat Han described as “somewhat unreliable.” She reassures us that the team is in process of securing a spare motor to continue improving the vehicle.

Lightweight constraint

Phoenix is lightweight and aerodynamic like most practical solar cars. Seating capacity is limited to one seat to maximize solar panel area coverage and reduce excess weight. Weight management is very significant in a system aimed at conserving power because the larger the mass, the larger the required propulsion force, and the subsequently the greater amount of power needed to fuel that force. For this reason, solar cars aspire to be as lightweight as possible while preserving structural integrity.

Close proximity to a titanium producer allowed OSUSVT to build Phoenix’s frame and suspension out of titanium. The shell of the car itself was constructed out of pre-impregnated carbon fiber selected for its light weight and durability. Acquiring such expensive materials on a tight budget is part of the challenge most university level solar car teams must resolve. Typically, teams establish sponsorships with companies such as National Instruments’, Composites Universal, Lancair, and Boeing in OSUSVT's case.

Solar power outputs

According to Han, Phoenix’s solar array outputs just over 1 kW in full sunlight. The power is then sent to three maximum point power tracks (AERL MPPTS), one for each array. Next the voltage is stepped up from 70 V coming out of the array to 110 V going by these trackers.

Solar panel lamination

The CompactDAQ and LabVIEW system design software provided by National Instruments enabled the team to test solar modules prior to laminating them. The system revealed any problems with the solar arrays, before and after the lamentation. CompactDAQ was essentially to controlling the entire lamination system; it operated the vacuum solenoids, a heater, and read feedback thermocouple. Han says, “LabVIEW also enabled our team to design a simple state machine that steps the laminator through the different stages of our lamination protocol.”

Future proliferation

Kat Han points out this technology has long existed in consumer automobiles, dating back to the 1990s when GM participated in the SunRayce (Now the American Solar Challenge). However, she also highlights that neither of these two examples include solar modules and that the “transportation industry has a long way to go before developing completely solar-powered vehicles.” Highway-legal vehicles and electric vehicles are far too heavy to be completely supported by solar power.

Han indicates that the majority of vehicles have significantly less surface area to hold a solar array than solar race cars. Assuming the vehicle uses half the panels (three square meters) with 500 W of solar input, the energy draw for most vehicles per mile is about 0.1 lbs. With that said, a 2,000 lb vehicle may consume 200 Whr per mile and drive 2.5 miles after an hour of charging. She quickly points out the futility in this, “in order to fill up your 100 mile battery pack, you would need to sit it in the sun for four days.”

“I think consumers can be more energy efficient by putting solar cells on their roofs and driving electric vehicles. Of course, there is still a lot of opportunity for growth and innovation with solar vehicle challenges”

OSUSVT assembled at the Circuit of The Americas in Austin, TX.

Contests such as FSGP are what Han believes to produce creative and experienced students capable to think outside of the box, and I agree. There's something honorable to be had with the expression, less is more, and perhaps we as human beings need to learn to incorporate this lean philosophy into everything else. After all, resources are limited.

Click here to view the full interview with Kat Han

Advertisement

Learn more about Electronic Products Magazine