Individual terminals and pins are poorly suited for pick-and-place carrier tape packaging due to their geometry. So it’s often necessary to add an accessory to the part to accommodate packaging and automated assembly, especially in high-volume production environments that necessitate automatic assembly but don't require an insulator. Mill-Max's new spring-loaded pins fill that void in automated assembly with the introduction of removable pick-and-place caps.

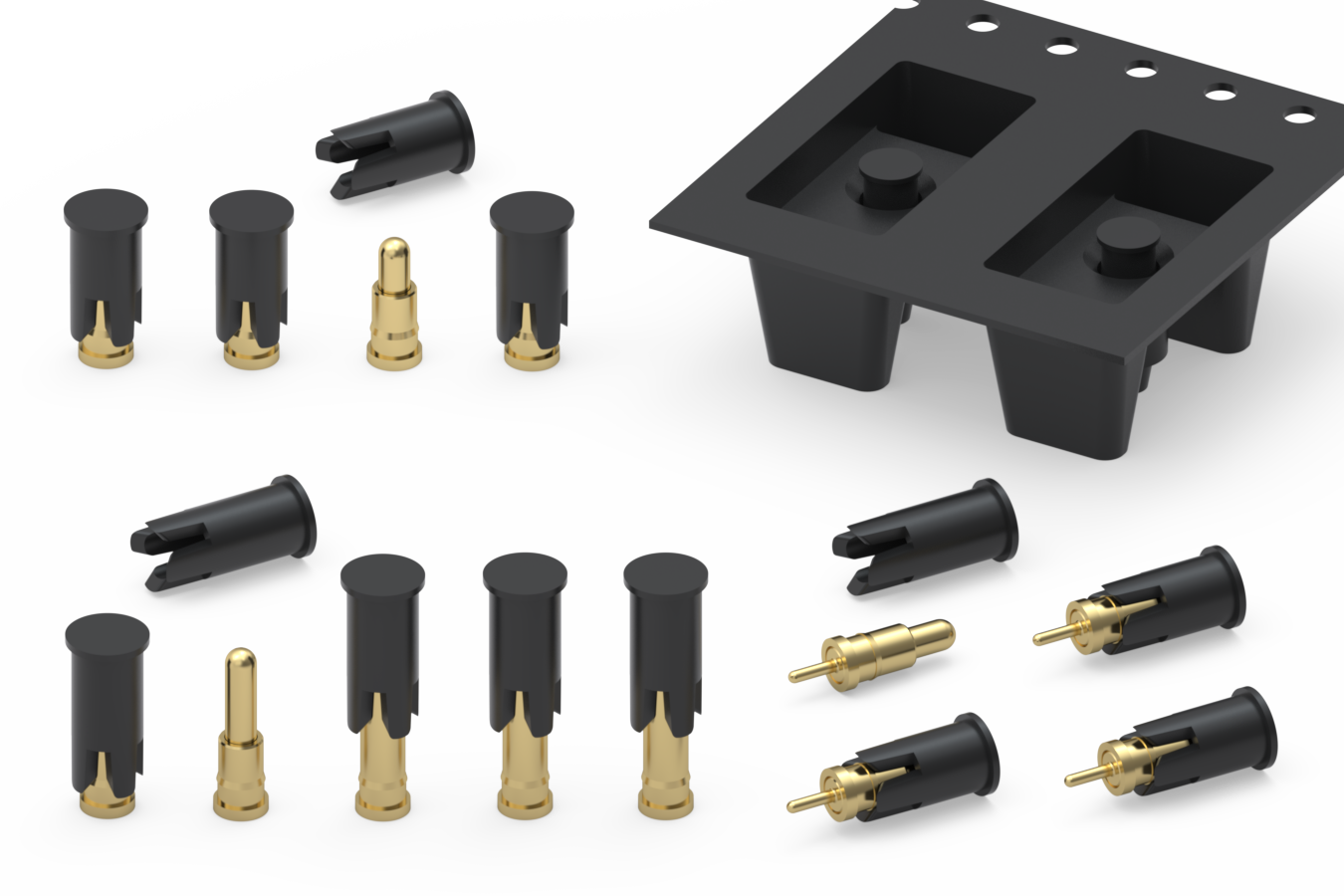

The spring pins with removable caps in the new 806 Series keep parts centered on the carrier tape pocket by presenting a large, round target surface for vacuum pick-up so that caps can be easily removed after the soldering process. These removable caps are made of high-temperature nylon 46 and are suitable for most soldering processes.

The removable caps, attached to the body of the spring pin, slip over without compressing or damaging the plunger. And the four-finger design makes the cap easier to remove. Also, the closed flat top ensures a reliable vacuum pick-up.

Mill-Max's new spring pins also feature precision-machined external components and high-reliability internal springs. Moreover, the gold-plated components and springs ensure conductivity, corrosion resistance, and durability.

The 806-22-001-30-0XX191 Series of spring-loaded pins is available in nine surface-mount options using standard Mill-Max spring pins 0900-X and 0907-X. Next, the 806-22-001-10-00X191 Series is available in four through-hole-style spring pins 0906-X.

Advertisement

Learn more about Mill-Max