STMicroelectronics gave the industry its first look into the company’s integrated STi2GaN family of GaN power devices for automotive applications at the PCIM Europe virtual conference. Leveraging TSMC’s GaN technology with its own unique design and package expertise, the new GaN devices, including 100-V and 650-V monolithic chips and 100-V ASSPs, claim reduced parasitic inductances, excellent thermal dissipation capability, fast switching, and high-frequency operation in a compact package for space and cost savings.

The STi2GaN solutions build a multi-fold offering from a monolithic power stage with a driver all the way up to control logic integration, and use innovative bond-wire-free packages to provide high robustness and reliability, said Rodrigo Marquina, ST’s senior technical marketing engineer during the PCIM presentation, A New Wave of Smart Power Electronics.

TSMC provides the GaN technology, including 100-V and 650-V e-Mode GaN, and because it is based on a p-GaN gate structure, the device is normally off, which is very important for automotive applications, said Marquina. “ST is providing a dedicated unique design with its own design rules. For the 100-V devices we go a step further, and in a system-in-package approach, we integrate logic with our latest silicon-based technology, the BCD9 technology. This provides a simpler GaN power gate voltage driver, while at the same time enabling high-speed logic control.”

Marquina explained the new family addresses three different “blocks” – the power stage, driver for the power stage and device protection, and the logic control. These devices are available as either monolithic GaN power stages with driver and protection or as system-in-package (SiP) devices that integrate the monolithic GaN power stage, plus the driver (GaN or silicon) and a silicon controller.

The integrated GaN power devices also deliver a compact size. “Once everything is integrated then we have reduced parasitic inductances, increased robustness, and all of these bring improved reliability,” he said.

This is in combination with high performance attributes with the integrated device. “We have high frequency operation inherited from the GaN switching capabilities,” he said. “At the same time, we lower the EMI and due to our bond-wire-free packages like LISI we improve enormously the thermal dissipation.”

Fine-tuned portfolio

The STi2GaN portfolio offers solutions from a monolithic power stage with a driver all the way up to control logic integration, which combines TSMC’s GaN technology and ST’ silicon-based BCD technologies along with novel bond-wire-free packages.

The family is divided into 100-V and 650-V applications. In the 100-V area, the first devices target 48 V/12 V DC/DC converter and LiDAR applications. These devices are developed using a system-in-package approach, which means the power stage uses GaN technology, while all of the integrated control and protection is in silicon.

“Talking more specifically about the first application – the bidirectional 48 V/12 V DC/DC converter – it’s a monolithic GaN half-bridge with a high side (HS) of 2 mΩ and the low side (LS) of 1 mΩ with the driver and controller in silicon,” said Marquina.

“This integration allows a switching speed up to 1 MHz and if we go for a more typical PWM or 500 kHz, our target efficiency is 98%, and this approach is suitable to address centralized as well as distributed power architectures,” he added. “In both cases [centralized or distributed], we reach 900 watts per phase per device with a system efficiency of up to 98% and a switching frequency of up to 1 MHz,” Marquina said.

For the LiDAR application, it needs high-density power pulses, but in a very short time, Marquina said. To meet this application, ST is developing a single-channel laser driver as well as a four-channel laser driver and each of these devices will be able to deliver 50 amp pulses in a rise time of only 400 picoseconds.

ST also is developing a spin-off of the 100-V technology, which is a full-bridge monolithic GaN device with the driver and the protection functions.

The 100-V devices are housed in small and thin 2SPAK package, which offers extremely good thermal performance thanks to a cooling plate that dissipates heat.

First engineering samples of the 100-V ASSPs are available to start evaluation. ST expects qualified samples by Q4 2023.

The first members of the 650-V family are segmented into devices for OBC and auxiliary power supply applications. The low-ohmic OBC devices are 30 mΩ and 65 mΩ fully monolithic low-side (LS) HEMTs with integrated driver and protection circuits, so not only the power stage, but also their control use GaN technology, said Marquina.

“By not using silicon this allows us to increase the switching frequency up to 2 MHz, and not only that we also are able to program the dV/dt and it includes all the protection like short circuit and thermal protection.”

ST selected a LISI slug-up package for these LS HEMTs, which offer “extremely reduced parasitic contributions, dual-side cooling for an excellent thermal performance, and flexibility in pad positioning and the number of vias,” said Marquina. It is also compact and thin, measuring 6 × 5 × 0.8 mm.

The first high-ohmic devices will start at 190 mΩ and range up to 500 mΩ. These also are monolithic LS HEMTs, but they integrate a PWM controller, along with the driver and protection circuits. “We still have a programmable turn-on dV/dt and also include variable PWM duty cycle, and, of course, the advantage of having a very low standby current,” said Marquina.

First engineering samples for the 650-V devices are available. Qualified samples are expected at the end of 2023.

Stray inductances: discrete vs. integrated solutions

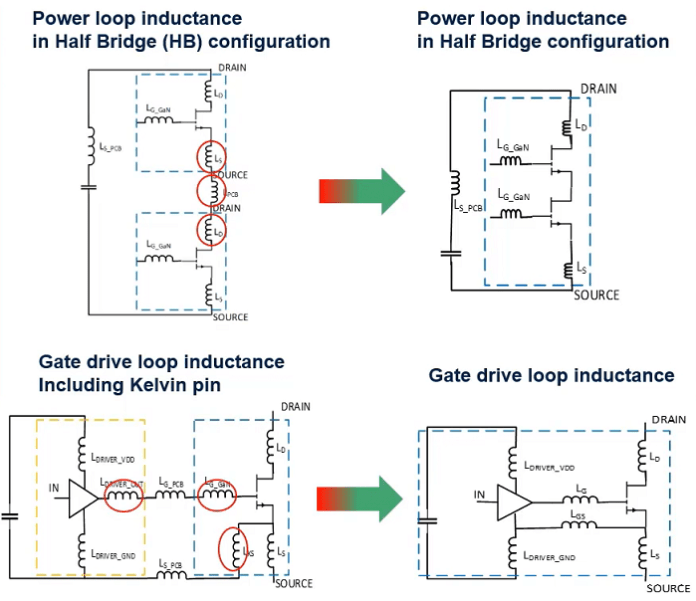

A key advantage of GaN is its very high switching capability, but with fast switching comes the problem of stray inductance. Marquina said the integrated solutions offer benefits in dealing with the problem of stray inductances, while providing space savings, up to 40 percent by reducing the size and number of external components.

Looking at a discrete GaN solution, there are a couple of types of stray inductances that need to be addressed. “We need to take care of the gate drive loop stray inductance, which increases the likelihood of a false turn-on and, of course, brings additional gate stress,” said Marquina.

“The secondary inductances that we need to take care of is the power loop. Stray inductance in the power loop may cause higher voltage spikes that will add more stress to your device,” he added.

Marquina also noted that a gate dumping resistor and a multilayer PCB with an optimized layout are necessary to reduce the effects of these stray inductances, which translates into additional resources, time, and cost.

Discrete GaN (left) versus integrated GaN (right) solutions. (Image: STMicroelectronics presentation)

With the integrated STi2GaN solution, looking at the gate drive loop, it “drastically reduces the gate source voltage ringing. By lowering the stress on the gate structure, this gives us improved reliability,” said Marquina. “We also reduce the damping resistance on the driver output and this enables a faster switching and by default lowers the switching losses.”

Concerning the stray inductances in the power loop, the STi2GaN solution “also drastically reduces the drain source voltage spikes and as a result it lowers the switching losses, as well as EMI, and the drain source voltage stress.”

But it’s not all about stray inductances, said Marquina. “Size matters. It matters in the PCB size cost, the number of passive components, and the volume that your system occupies in the OEM structure is cost, which is sometimes difficult to quantify.”

Using the example of the 48 V/12 V DC/DC converter STi2GaN solution versus a comparable discrete silicon solution, Marquina said the integrated STi2GaN “drastically reduces the number of external components.” This includes the number and size of the net capacitors for either the 48-V or 12-V side and the devices needed for the power stage and protection. This can reduce the size of the application by roughly 40 percent, he said.

As a wrap-up, Marquina noted that the STi2GaN provides fast switching while reducing stray inductances, and the integrated solution eases system implementation, reduces space constraints, and improves overall efficiency.

Advertisement

Learn more about STMicroelectronics