Scientists at Stanford University have developed a low-cost, emissions-free device that produces hydrogen by water electrolysis. The device uses two electrodes that split liquid water into hydrogen and oxygen gas using only 1.5 V. Unlike other water splitters that use precious-metal catalysts, the electrodes in the Stanford device are made of inexpensive and abundant nickel and iron — nanoscale nickel oxide/nickel heterostructures formed on carbon nanotube sidewalls.

Hongjie Dai, a professor of chemistry at Stanford, noted that “this is the first time anyone has used non-precious metal catalysts to split water at a voltage that low. It's quite remarkable, because normally you need expensive metals, like platinum or iridium, to achieve that voltage.”

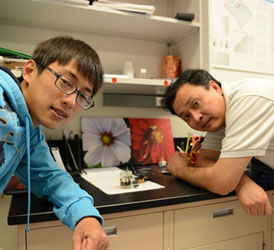

Stanford graduate student Ming Gong (left) and Professor Hongjie Dai (Image: Mark Shwartz/Stanford)

The device was discovered by graduate student Ming Gong, co-lead author of the study. He and his colleagues describe the new device in the August 22 issue of the journal Nature Communications . “Ming discovered a nickel-metal/nickel-oxide structure that turns out to be more active than pure nickel metal or pure nickel oxide alone,” Dai said. Gong added, “The electrodes are fairly stable, but they do slowly decay over time. The current device would probably run for days, but weeks or months would be preferable. That goal is achievable based on my most recent results.”

Automakers have long considered a vehicle powered by a hydrogen fuel cell. Large industrial plants produce hydrogen by combining very hot steam and natural gas, an energy-intensive process that releases carbon dioxide as a byproduct. Splitting water by electrolysis to make hydrogen requires no fossil fuels and emits no greenhouse gases. But scientists have yet to develop an affordable, active water splitter with catalysts capable of working at industrial scales. This new device is a step in the right direction.

Advertisement

Learn more about Electronic Products Magazine