A new company called Carbon3D has unveiled a 3D-printing process that is between 25 and 100 times faster than the ones currently on the market.

The company calls its technology Continuous Liquid Interface Production technology (CLIP) and it works by using light and oxygen to create a photosensitive resin (similar to the process of Stereolithography which uses lasers to create such resin).

Traditional 3D-printing methods involve printing objects in layers which is really just repetitive 2D printing. As a result, 3D-printed parts can take hours and days to produce and can even have a weak consistency.

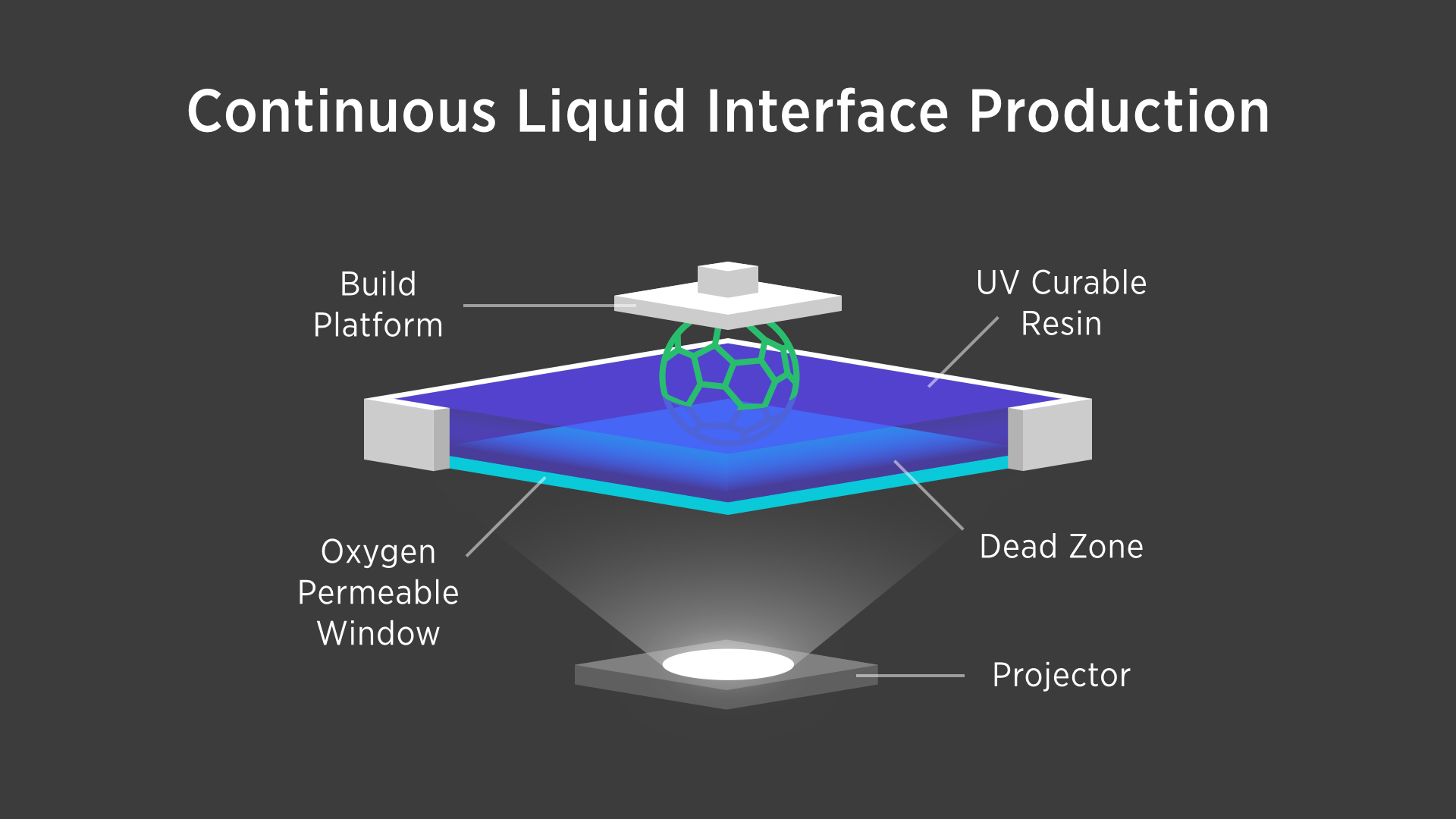

Carbon3D doesn’t use this layering system. Instead, it carefully balances the interaction of UV light, which triggers photopolymerization and oxygen and inhibits the reaction to continuously grow objects from the pool of resin.

How it works. (Image via Carbon3D)

How it works. (Image via Carbon3D)

The process involves a special window that is transparent to light and permeable to oxygen, much like a contact lens.

Carbon3D explains how it works on its website:

“By controlling the oxygen flux through the window, CLIP creates a “dead zone” in the resin pool just tens of microns thick (about two to three diameters of a red blood cell) where photopolymerization cannot occur. As a series of cross-sectional images of a 3D model is played like a movie into the resin pool from underneath, the physical object emerges continuously from just above the dead zone.”

Watch the demonstration below.

Carbon3D has partnered with Northgate Capital and Sequoia Capital for a total raise of $40 million to commercialize the technology.

Learn more at Carbon3D.

Advertisement

Learn more about Electronic Products Magazine