By Jim Harrison

Resistors that tolerate pulse or surge are required for pre-charge resistors, ESD protection, and lightning protection. There are a large number of pertinent specifications for different use cases and circuit types and we will not cover them here. You will notice two types of specifications. For these types of resistors, pulse means the overload of large power and with long duration (large energy), like lightning, whereas surge means overload, like ESD, of high voltage and with short duration.

Resistors for lightning protection in telecommunications fall under test requirements laid down by the International Telecommunications Union (ITU) and Bell Communications Research (Bellcore). These resistors are protected from the high-energy lightning surge by over-voltage protection in the system.

European specifications, based on the IEC 61000, are generic specification EN 60115-1. This specification defines several test and measurement procedures. It suffices for this article to say that this spec covers pulse durations from 10 μs to 100 ms, which is good for applications like ESD protection, most motor and solar energy surge protection, and pre-charge circuits.

For ESD tests, there are component-level, board-level, and system-level versions. The component-level (IC-level) ESD and the system-level ESD test requirements are very different because they address different ESD environments. The ESD current waveforms associated with the two tests differ significantly in terms of peak current, duration, and total power. The IEC 61000-4-2 is recognized industry-wide as the standard for end-product or system-level ESD rating, and this surge level is much higher than HBM.

The standard human body model (HBM) current waveform has a rise time between 2 and 10 ns. The IEC 61000-4-2 standard for end-product ESD, or system-level testing, uses 2 to 8 kV for a duration of 1 second. This test is done from the outside of a piece of equipment.

In the past, axial-leaded devices dominated the protection resistor market. Carbon composition devices with low inductance were popular and wire-wound units have good surge handling and excellent precision, but neither technology is ideal for high-voltage pulses. Ceramic composition resistors are good at handling both high-voltage and high-energy pulses; however, they typically come only in ±10% tolerances, are rather expensive, and their overall stability is inferior to wire-wound and film-based resistors.

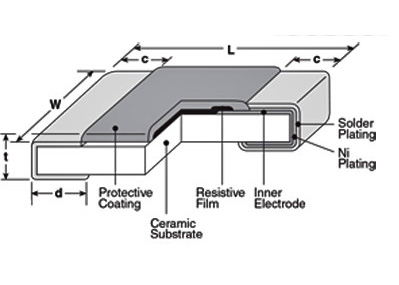

For a film resistor, the element is typically a thick-film material that is coated for higher-voltage handling. This technology is inexpensive and is a good choice for applications with moderate power requirements. Thick-film technology has improved significantly in the past few years and it offers smaller surface-mountable packages.

Surge rated resistors are usually not precision

Standard thick-film chip resistors are laser-trimmed for accuracy. The cut is across the width of the part, which can narrow the effective width of the resistive element by as much as 40%. This can vary greatly from one manufacturing lot to another. This results in a variability in the pulse handling capability and makes using standard thick-film chip resistors for pulse handling situations difficult. Pulse-withstanding chip resistors are designed to maximize the usable width of the resistive element, which reduces or eliminates the hot spot on the resistor where current crowding occurs. Thus, surge rated devices are usually not trimmed and have ±5% to 20% tolerance.

For film resistors, it’s important to understand that for high pulse current handling, the resistive element width is maximized, but for high-voltage pulse handling, the resistive element is made long and narrow; opposite design criteria. Also note that for handling direct discharges in a system, you need to use primary clamping devices (TVS or Varistor) in addition to the series resistor or use resistors designed for high voltages — which might require going to a through-hole device.

Let’s have a look at six of the many, many suppliers of surge rated resistors. I chose to look at surface-mount devices only for this review, though there are many leaded products available. I also choose to use a 1-ms surge time interval — hoping it is representative of the various use cases and standards for ESD protection. The devices listed here may be useful for lightning protection circuits as well as ESD.

Example products

The NRCP series from NIC Components uses an RuO2 film with a protective overcoat and comes in sizes from 0603 (0.1 W) to 2512 (1.0 W). The 2512 version will handle approximately 700 W for 1 ms (one pulse limiting power). Resistance values range from 10 Ω to 1 MΩ, with 5%, 10%, or 20% tolerance and 200 ppm TCR. Power is derated from 70°C to 155°C.

Ohmite offers their AS Series anti-surge thick-film chip resistors in 0805, 1206, and 2512 sizes with working voltages of 150, 200, and 500 V, respectively. Operating range is −55°C to 155°C, TCR is 400 ppm, and values range from 1 Ω to 20 MΩ. For 1-ms pulses, the resistors have a single pulse power rating of 55 W for the 0805 size and 1,000 W for the 2512 size. Continuous pulse power rating ranges from 13 to 750 W for 1-ms pulses.

KOA Speer offers the SG73 series of surge current flat chip resistors with sizes from 0603 to 2512 and power rating from 0.1 to 1 W. Tolerance is ±10% or 20% with 200 or 400 ppm TCR. Working voltages are 50, 150, and 200 V. For the 2512 size, the one pulse limiting power is 750 W at 1 ms.

Vishay Intertechnology has a new series of anti-surge thick-film chip resistors for automotive and industrial applications. Devices in the AEC-Q200-qualified RCS e3 series offers power ratings from 0.2 to 0.5 W in 0402, 0603, 0805, and 1206 case sizes. The 0.25 W RCS0603 version is said to cover the power ratings of “standard” 0603, 0805, and 1206 devices. The series offers resistances from 1 Ω to 10 MΩ with tolerances of ±0.5%, 1%, and 5% and TCR of 100 or 200 ppm.

Operating voltage range is 50 V to 150 V. They are tested according to EN-60115-1 4.27; 10 µs/700 Ωs; 10 pulses at 1-min. intervals; for permissible resistance change of 1%. At 1 kΩ, pulse ratings run from 100 to 300 V peak, for the three sizes.

The SR chip resistor series from Yageo comes in two flavors. The standard ±5%, 10%, and 20% versions have a 1-ms pulse withstanding rating of 680 W for the largest size (2512) and 3.8 W for the smallest (0402). The tighter tolerance 0.5% and 1.0% versions have a lower withstanding rating of 175 W for the largest size and 3 W for the smallest.

They come in 10 sizes with power rating from 1/16 to 1.0 W and values between 1 Ω and 100 KΩ. Working voltage is from 50 to 200 V. Temperature coefficient is ±200 ppm.

Stackpole has the RPC and RPC-HP (high-power) pulse withstanding thick-film chip resistor series. It has 0.1 (0603) to 1.5 W (2512) power rating ratings with working voltage as high as 500 V and tolerance as good as ±0.5%. The series offers 1 Ω to 20 MΩ values. Single pulse power ratings (100 Ω) for the largest version (2512) are 380 W for the standard and 1,050 W for the HP version for a 1-ms pulse.

Advertisement

Learn more about KOA Speer ElectronicsNIC ComponentsOhmite ManufacturingStackpole ElectronicsVishay IntertechnologyYageo USA