The availability of microwave CVD diamond as an optical engineering material has opened up a number of new applications in high-power laser systems based on the combination of a number of extreme properties that only they offer. The properties involved are its very wide transparency (ranging from UV to THz frequencies), its superb heat conductivity (highest thermal conductivity of any solid at room temperature), and high refractive index, mechanical strength, and stability. These properties enable the highest power levels of laser light to be handled by the optics with high performance under the harshest conditions.

Control of the CVD diamond synthesis process is key to ensuring the consistency of the properties and availability of this unique material, in either single crystal form or polycrystalline wafers. A recent application enabled by these extreme materials properties is for EUV lithography, where a CVD diamond is the essential for use with the high-power CO2 drive laser of the system. No other known material can handle the 35 to 40-kW CO2 laser power.

Unique properties

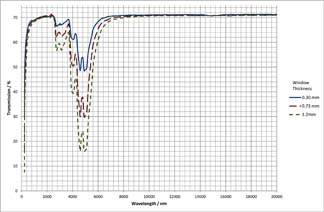

First, the transmission spectrum of intrinsic microwave CVD diamond is from UV to far IR, as shown in Fig. 1 . The absorption edge at 225 nm corresponds to the indirect band gap and results from absorption as electrons are excited from the valance to the conduction band of the material.

For material with very low defect densities, the transmission through the visible and near-IR wavelengths increases to around 72% which improves to >99.5% with AR coatings. The intrinsic transmission is limited only by reflection and a small amount of scatter in polycrystalline material. This can be observed from the variation in transmission with thickness as shown in Figure 1, with transmission only dropping significantly in the multi-phonon region, where absorption is the dominant loss mechanism, while at long wavelengths, where absorption is not significant, the transmission for various thicknesses are similar.

Fig. 1: Transmission spectrum for CVD diamond windows of various thicknesses.

The thermal and mechanical properties of CVD diamond are important for applications where the CVD diamond is a pressure window, or where there are high levels of optical power transmission. In high power transmission applications, the extremely high thermal conductivity keeps any temperature gradients across the element to a minimum and this reduces both thermal stresses and thermally induced refractive index variations. The material strength affects the thickness required for any pressure window and also applies to the window's capacity to survive impacts.

Thermal and mechanical characteristics

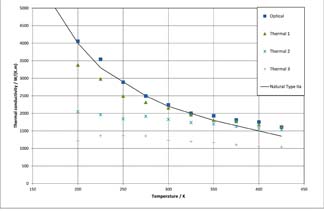

For the highest quality grades of polycrystalline CVD diamond, the through plane thermal conductivity is largely indistinguishable from that of type IIa natural diamond at or above room temperature (see Fig. 2 ). CVD diamond, as with other electrical insulators, conducts heat primarily via phonons. In contrast to other phonon-dominated thermal conductors, its Debye temperature is high, contributing to its room temperature thermal conductivity being extremely high.

Fig. 2: Thermal conductivity as a function of temperature for optical and thermal grades of polycrystalline diamond compared to natural type IIa.

For polycrystalline diamond with well intergrown grains, the fracture strength is controlled, as in other ceramics, by the maximum critical flaw size in the grains. For optical grades of polycrystalline diamond, the most comprehensive data has been gathered using three point bend tests as listed in Table 1 . CVD diamond's strength is determined by the local critical flaw size, and the spatial distribution of these flaws determines the strength of any test piece. Therefore the Weibull modulus for these tests are given alongside fracture strengths.

|

Optical grade polycrystalline diamond |

Single crystal diamond |

|

|

Fracture strength |

450 MPa (Growth side) 1030 MPa (Polished nucleation side) [9] |

2860 MPa |

|

Weibull modulus |

15 (Growth side) 11 (unpolished nucleation side) |

2.5 |

|

Thermal conductivity (300K) |

>2000 W m-1 K-1 |

>2000 W m-1 K-1 |

Table 1: Mechanical and Thermal properties of CVD diamond.

Advertisement

Learn more about Element Six