As the world transitions to a low-carbon economy, demand increases for electronic components that support advanced, efficient and clean technologies. Current sensors play an important role in this transition, as they help optimize energy usage in renewable technologies, electric vehicles and efficient power systems.

The ever-continuing complexity and miniaturization of electronics also make accurate and efficient current monitoring more important than ever. Isolated current sensors enable precise measurements while ensuring electrical separation to enhance safety and reliability. As industries embrace renewable energy sources and consumers adopt more electric-powered forms of mobility, these sensors can prevent ground loops and offer protection against systems with increasingly high voltages.

Types of current-sensing applications

Current sensors are used in a wide array of applications to ensure optimal performance, safety and efficiency.

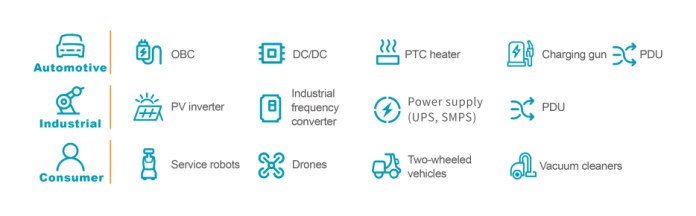

Current sensors play an important role in many different types of applications, including EVs and renewable energy systems. (Source: Novosense Microelectronics)

In the area of renewable energy, photovoltaic inverters rely on current sensors to monitor and control the flow of electricity, maximizing energy output and grid integration. In industrial settings, current sensors are integral components of inverters used in manufacturing processes, motor control and robotics.

Power supplies utilize current sensors for monitoring load currents, enabling efficient regulation and preventing overloads. Uninterruptible power supplies depend on current sensors to safeguard critical systems by detecting anomalies and ensuring a seamless transition to battery power during outages to preserve data integrity.

EVs employ current sensors in various aspects of their powertrain, such as battery management, motor control and charging systems. These sensors contribute to the overall safety and efficiency of EVs by precisely measuring current flow. Current sensors also find applications in emerging technologies, such as internet-of-things devices.

Key criteria for choosing current sensors

Choosing the right current sensor involves careful consideration of several important criteria to ensure optimal performance in various applications. Accuracy is one of the most important factors, as it directly influences the precision of current measurements. Linearity is another vital parameter, ensuring that the sensor’s output corresponds linearly to the input current. A linear response simplifies calibration and enhances overall system accuracy, particularly in applications in which precise control is essential.

In addition, thermal adaptability is an important consideration to ensure the sensor’s performance will be maintained across varying temperatures. This is particularly important in industrial or automotive applications, in which temperature fluctuations can be significant.

Signal bandwidth in current sensors refers to the frequency range within which the sensor accurately samples and measures the current signal. Choosing a current sensor with an appropriate signal bandwidth is crucial for maintaining precision and reliability in applications with fast-changing current profiles, and a broader bandwidth is essential for applications in which high-frequency components are present.

Current-sensing techniques

Two of the most common types of current sensors are shunt resistors and Hall-effect sensors. Shunt resistors introduce a small resistance in the current path, and the voltage across the resistor is proportional to the current. This voltage drop is then measured for current determination.

Hall-effect sensors use the Hall-effect phenomenon, whereby a magnetic field influences the movement of charge carriers. As current flows through a conductor, the sensor module detects the magnetic field generated, providing a voltage output proportional to the current.

A more advanced option is the integrated current sensor IC, a compact electronic device that consolidates current-sensing functions into a single chip.

The different types of current sensors available and where they are most commonly used in EV applications (Source: Novosense Microelectronics)

Benefits of integrated current-sensing ICs

Integrated current-sensing ICs offer many advantages in electronic systems. Unlike sensor modules, they detect current by sensing the magnetic field generated by the current flowing through the internal primary conductor of the chip (Hall IC) based on magnetic-field-detection technology. Their compact design consolidates current-sensing functionality into a single chip, simplifying circuit design significantly. The integration enhances precision and accuracy, minimizing any possible errors associated with external components.

However, because they are more structurally constrained, the chips typically face heat-dissipation challenges when measuring large current, and therefore, the level of current measurement they can achieve is more limited than current sensor modules. At present, they are mostly used in components with a low current rating, such as on-board chargers (OBCs) and DC/DC converters. Because the current flows through the sensor itself, in addition to meeting accuracy requirements, the Hall current sensor packaging structure must also meet high isolation requirements.

A high-precision, high-reliability solution

One example of a chip-level current sensor is the Novosense NSM201x Series for isolation measurement with a wide current range (2.5 A to 200 A). The series is suitable for a range of applications, including photovoltaic inverters, automotive (OBCs, DC/DCs, charging guns and PTC heaters), industrial inverters, power supplies, service robots, unmanned aerial vehicles and two-wheeled vehicles.

These sensors are smaller than conventional Hall sensor modules, reducing the footprint by over 50%. Internally, they adopt dual Hall differential sampling and effectively reduce the impact of external common-mode magnetic fields. The single-chip integrated technology solution has impedance resistance values of 0.27 mΩ (SOW10 package), 0.8 mΩ (SOW16 package) and 1.2 mΩ (SOP8 package) and reduces heating while conducting large current sensing.

These current sensors provide a working voltage level for a basic insulation of 1,550 Vpk, and they can endure a 10-kV surge voltage and 20-kA surge current without adding any protective devices. They also have a dielectric withstand voltage of 5,000 Vrms, easily meeting the voltage and current surge requirements for EVs.

The Novosense NSM201x series is available in three package types: SOP8, SOW16 and SOW10. (Source: Novosense Microelectronics)

By enhancing the efficiency of current sensing and insulation measurement, the NSM201x series contributes significantly to sustainability, reduced emissions and enhanced energy efficiency in modern electronic designs.

Advertisement