Slowly but surely, every kind of industry is moving into the future, including the factories where it’s all put together. Global suppliers are now looking for ways in which to create the factory of the tomorrow; pinnacles of the industry that combine the best of technological and manufacturing advancements to feed a supply chain that is constantly growing larger and more demanding by the hour.

Smart factories use digital technologies to increase profit; cut costs

One improvement made over the years is interconnectivity between a factory’s computers, robotics, and operating systems. While these technologies might seem standard nowadays, robotic arms were not always the norm, nor has it always been possible to do things like automatically test chipsets before packaging or power electronic subassemblies for testing as they are being built.

In order for manufacturers to transition their current factory conditions into tomorrow’s smart, efficient supply units, these connectors are now expected to also transfer high-speed data, operate in a wide range of new configurations, and withstand harsh environments; they must also be easy install and repair in the field.

To meet this long list of must-haves, global manufacturers are turning to TE Connectivity’s (TE’s) diverse roster of engineers, experienced in the areas mentioned above and more, in order to create products and solutions that will allow their supply unit to meet all of tomorrow’s demands.

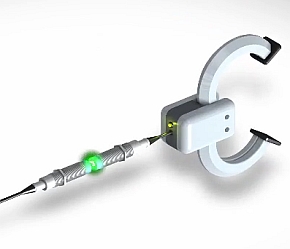

Case in point: TE engineers worked with manufacturers to develop the ARISO contactless connectivity platform, one of the company’s promising new products that will usher in a new age of factory automation, even in the most unforgiving settings.

ARISO contactless connectivity eliminates the need for a physical connection between the couplers

“Imagine your machine being used in a harsh environment, like an oily, dirty, greasy environment or even explosive environments,” says TE fellow Jan Broeksteeg. “When you want to change the tools and equipment on the machine, you actually have to power that machine down because there’s a risk for arching and therefore explosions. But if you do this contactless, that allows multiple applications—you could even replace parts of that machinery without having to switch off the complete machine.”

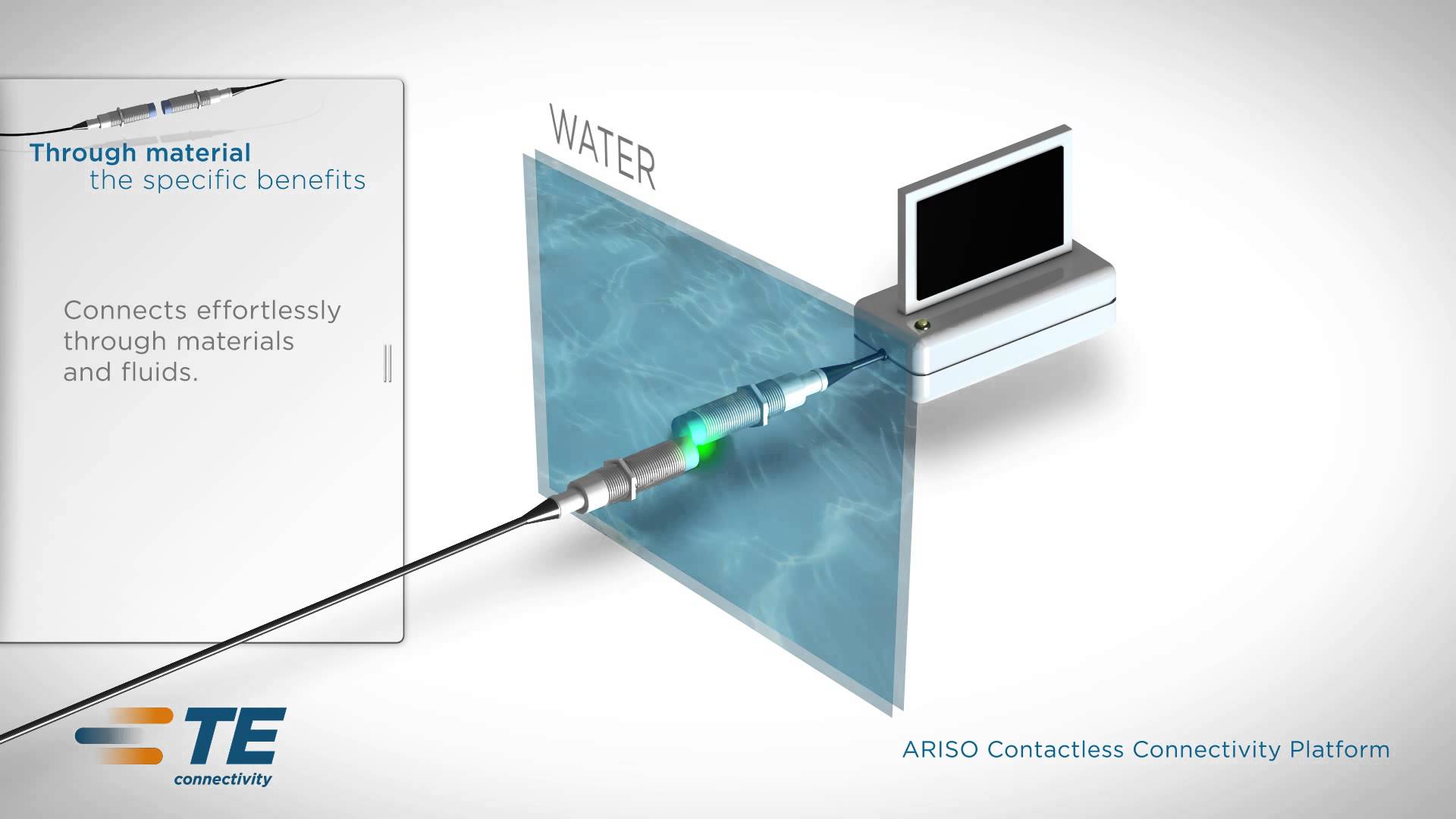

Specifically, the ARISO contactless connector diffuses significant problems for global suppliers and customers by transferring both unidirectional power and bidirectional data through materials like plastic, paper and oil without a physical connection.

ARISO platform connects easily through materials like water and paper

The ARISO contactless connection is an innovative solution that will have a profound effect on the future’s smart factories, allowing industrial equipment to be more flexible by allowing for sudden tool changes, real-time product testing and design alterations.

It should be noted that the ARISO contactless connectivity platform is not an off-the-shelf solution,. According to TE Connectivity Manager of Electrical Engineering Mohammad Ahmed, it was only developed because of the tight-knit collaboration between TE and manufacturing engineers.

“In order to facilitate [greater flexibility] we needed to get in touch with the manufacturing engineers face to face, in order to find out what their problems are, what their needs are,” says Ahmed. “Once we understand their problems, we can go back and find a solution—and if they agree upon that solution, we continue collaborating on it and bring that solution out to the market.”

While the applications of the team’s products are just now being explored, Ahmed is more than confident about how they will impact the industry. As mentioned earlier, the ARISO contactless connectivity platform is just one example of several TE products that address the unique industrial challenges today’s manufacturers are facing.

“We are, basically, changing the way industry works right now,” says Ahmed. “[The products] will have a big effect on manufacturing or industrial environments…because they bring a lot of flexibility and a lot of productivity to that environment.”

To learn more about design collaboration with TE Connectivity, visit www.everyconnectioncounts.com

TE, TE Connectivity and ARISO are trademarks.

© 2014 TE Connectivity family of companies

Advertisement