Light Emitting Diodes (LEDs) have changed the world and continue to change the world. When initially introduced, the limited brightness and color palette was somewhat of a novelty. To this point, filament-based illumination was the only choice for engineers designing indicators for instruments and equipment as well as lighting. Either as discrete bulbs, or as Nixie Tubes, filament technology was an adequate solution for the designs of the day and supplanted older light sources like gas, oil, or carbon lamps.

Initially, infrared (IR) emitters were designed for remote-control applications. Then the visible-red LEDs became available for lighting applications, which had advantages over visible filaments right from the get-go. First, the small active emitting areas of typically one-square mm could be mounted within low-cost plastic housings that could include a low-cost lens that could direct the light in a cone instead of a point-source emitter. This ability to create a divergent cone of illumination allowed higher brightness and better visibility for instrumentation and alerts.

Related is the fact that LEDs are more efficient and don’t create nearly the same levels of heat that filament-based illuminators do. This is the main reason that lower-cost plastics could be used instead of more expensive and manufacturing-intensive glass housings that could shatter, break, and be dangerous in some situations. LEDs also require lower power. More highly efficient LEDs means smaller power supplies and less current needed to achieve the same illumination. However, filament technology still hung on.

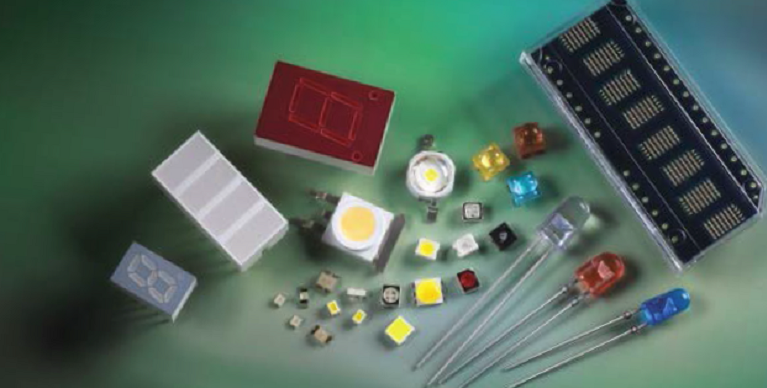

Fig. 1 – LED technology is a vital part of almost every design, and Avago is a leading supplier of virtually all types of LEDs and devices that embed LEDS.

A Long Plateau

For many years, red, green, and yellow LEDs were it. The only multicolor devices you could get were to combine a red and a green LED in the same package and vary each LED’s intensity to morph from red to green through variable yellows and oranges. It was pretty cool in the day, especially for alarm and alert levels where true analog levels could be conveyed as spectral shades. A single indicator could replace a bar graph or meter movement display (as long as you were not color blind).

What changed the trajectory was the blue LED. While early versions invented in 1972 showed it was possible, available products from 1989 on were not bright enough to displace other blue filament-based illuminators. Also because of this, white LEDs were not feasible.

The initial use of InGaN by Shuji Nakamura of Nichia Corporation in 1994 made variable color and white single-point emitters feasible and, yet again, changed the world. We have all seen how LED lighting has dominated all aspects of illumination, even creating high-definition video.

But, the journey is not complete. Advancements in shorter-wavelength devices have allowed these devices to emit shorter and shorter wavelength ultraviolet (UV). UV LEDs already are available and will continue to supplant CCFL bulbs, which are the present dominators of UV light-source emitters.

This is significant for a couple of reasons. First as energy efficiency becomes a more stringent constraint for all designs going forward, UV LEDs can replace UV bulbs used in sanitation devices, especially for the medical field. Second, the solid-state nature of an UV LED means it can co-exist with other emerging technologies like MEMS, nano fabrication, micro fluidics, and semiconductor sensors and processors to become part of a new more highly integrated functional unit.

These new lab-on-chip devices can and will be used for genetic testing, as part of a genetic fingerprint ID, since DNA fluoresces under UV. Chemical, biological, toxins, and explosive constituent compounds will also be identifiable helping make travel safer.

An Illuminating Source

LEDs are commonplace, but a manufacturer of quality parts spanning virtually all form factors and wavelengths are limited. Leaders like Avago

Technologies have all the expertise in-house and all the spectral solutions and packaging needed for most every design today and going forward. Avago’s LEDs and Displays feature both thru-hole and surface-mount packaging options and provide high-endurance and high-brightness solutions with longevity. For discrete components or integrated bar graphs, segment displays, and smart matrix and alphanumeric displays, if your design calls for LEDs, then check out the new LED Selector Guide, which allows quick and precise identification of the components needed to satisfy your demands.

And don’t forget Avago when it comes to applications that embed or support LEDs like photointerrupters, opto-isolators, fiber optics, and optical sensors.

Advertisement

Learn more about Electronic Products Magazine