By NORBERT PIEPER,

Senior VP Sales Business Development,

Vishay Intertechnology,

www.vishay.com

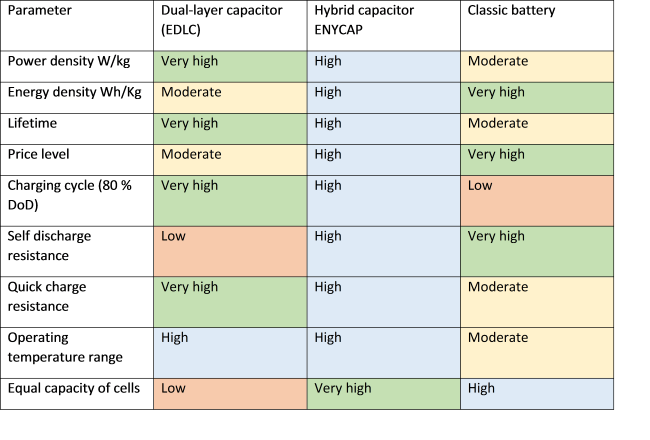

From home automation to industrial robots, our networked world demands that electronic systems offer constant availability, resulting in the need for permanent — often network-independent — energy supplies. Rechargeable batteries are practical and reliable for these systems until they reach the end of their working life, when they must be replaced or thrown away. Classic solid electrolyte capacitors provide a more environmentally friendly and cost-neutral alternative, but soon reach their limit with output requirements exceeding 100 mW. Supercap dual-layer capacitors offer high power density and long working life, but low dielectric strength. Electronic systems require a compromise between these technologies, solutions that combine the advantages of classic batteries and dual-layer capacitors without the limitations. Refer to the Table for comparison among the dual-layer capacitor, the typical battery, and the Hybrid ENYCAP capacitor.

Table: Basic comparison of the capacitor and battery systems.

The physical single cells of ENYCAP 196HVC devices have a nominal maximum voltage of 1.4 V and can be interconnected in series without special balancing measures, thus achieving higher nominal voltage. Currently, voltages of 8.4 V and capacitance values between 4 F and 90 F can be obtained.

Due to their low constructional height (

Fig. 1: ENYCAP structural form variations.

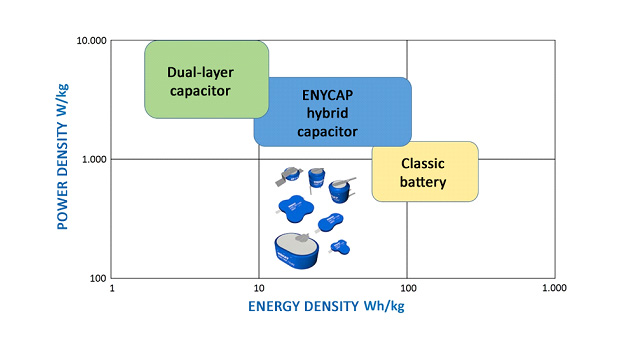

Hybrid systems can reach very high energy densities of >13 Ws/g (>3.6 Wh/kg) and are, therefore, a viable alternative to the classic battery. Furthermore, these energy storage capacitors are characterized by very low stray current and self-discharge.

The balance of power is demonstrated in Fig. 2 , which shows the optimum classification of ENYCAP storage capacitors according to today’s state-of-the-art technology.

Fig. 2: Balance of power chart for capacitors, batteries and hybrid capacitors.

As already implied in the examples above, specific parameters must be tuned to the respective application to select the correct component:

- Backup energy and time interval. Here, the periods between very deep discharging and, in particular, the time up until the first backup are particularly critical.

- Specific peak power and peak current requirements.

- Output voltage level for the backup solution; in particular, the minimum voltage level.

- Input voltage range that is available for loading the energy storage device; in particular, the maximum range.

- Impedance of the primary energy source. For systems with low ESR, extremely high charge current spikes can occur.

- Protection against complete discharging, short circuits, reverse polarity, overvoltage, and excess temperature.

- Charging status control of the energy storage device and data-bus-capable signals for advanced power management systems.

- Cost of the entire system.

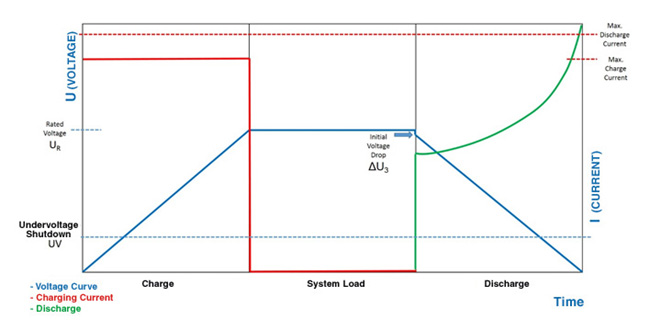

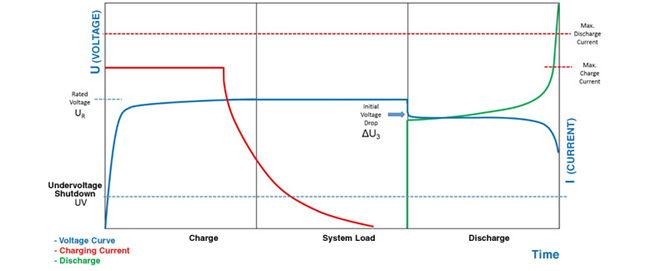

The parameters above are only a selection of the most important design parameters. To make the complexity clear, the following illustrations (see Figs. 3 and 4 ) of the principle will show the basic diagrams of charging current, discharge current, and voltage curve over time. The difference in the behavior between hybrid energy storage and classic supercaps can clearly be seen.

Fig. 3: Dual-layer capacitor as a backup source.

Fig. 4: ENYCAP as a backup source.

The good charging and, where applicable, fast charging behavior of dual-layer capacitors can be observed from the voltage plot. It can be seen that precautionary measures must be taken against extreme current charge peaks due to the low ESR. Furthermore, with constant backup power, the linear drop of the discharge voltage results in a disproportionate increase of the discharge current and constant back-regulation of the dc/dc converter as well as high current peaks. In some cases, higher ripple currents at the capacitor have to be taken into account.

The hybrid dual-layer capacitor is characterized by its more gentle charging behavior due to its higher series resistance and optimized construction. The nominal voltage on the capacitor is reached at a very early stage, allowing simple operation of wake-up switching and low-power sensor applications. The virtually constant voltage curve and resulting constant discharge current in the operating range are also advantageous. The control electronics can certainly be simplified as opposed to dual-layer capacitors. The relatively high initial voltage drop is a disadvantage.

To lighten the burden on the user caused by the differences in these systems, it’s important to provide the customer with complex solutions and design references that integrate the basic functions, such as charging and discharging (see Fig. 5), and the required protective circuits. The manufacturers of the storage elements and charge controllers must collaborate in advance, if possible, to adapt the specific conditions to the system.

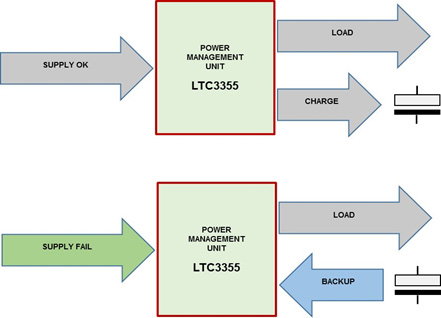

Fig. 5: Charging and backup block diagram using an LTC3355.

An example is a reference design that integrates an emergency current solution with a charge controller circuit and a backup converter, including the necessary current measurement sensors to evaluate the function as well as all protective functions. Moreover, this system can be operated using ENYCAP, dual-layer capacitors, classic capacitors, and batteries, and realizes automatic switching between primary supply plus charge function and energy source backup. For this purpose, charging voltage (1.3 V to 3.2 V), charging current (35 mA to 600 mA), discharging voltage (>1 V), and discharging current restriction (100 mA to 5 A) can be varied in several ranges and can easily be adapted to the customer’s circumstances. The charging process can use either constant current or constant voltage regulators.

The provided buck converter transforms to the programmed supply voltage for the load and charges the backup energy storage device. In case of an interruption of the supply voltage, the boost converter, which is also integrated, maintains the output voltage on the load without any interruption until the secondary energy source is exhausted. On top of this, a simple load switch on the output side switches off the load if the minimum capacitor voltage of about 1 V is undercut. This avoids complete discharging and constant linear operation of the connected regulators.

The LTC3355 IC performs all of the functions that are required, for example, within an intelligent power management system for a server or an IPC. Monitoring the voltages VIN, VOUT, and VCAP, basic information (open-drain signal outputs) regarding the load status of the energy source (CPGOOD) and the automatic switchover of the supply to the backup energy storage device (PFOB), as well as load regulation, are available. The regulator processes input voltages of 4.0 V to 20 V and supplies a regulated output voltage of 3.0 V to 5.0 V. The component has integrated overheating protection, which is also used to monitor the maximum permissible current.

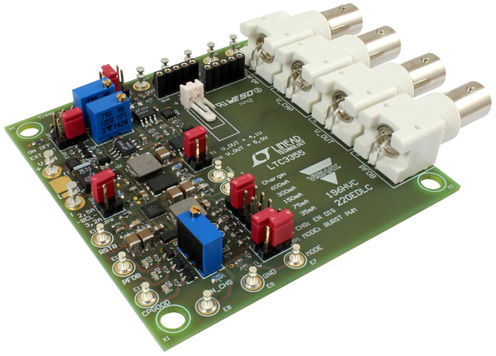

Fig. 6: Evaluation design kit (MAL219699001E3).

ENYCAP energy storage capacitors have a higher power density than a battery and higher energy density than classic electric dual-layer capacitors (EDLC). Therefore, faster charging and discharging times are possible than those for a battery. We suggest impulse charging for applications such as backup systems. The idea behind this is that the ENYCAP is initially charged up to the maximum of its energy storage capacity and then the charge status is maintained in a trickle mode by individual electrical impulses. This compensates for self-discharge and the capacitor is kept under ideal operating conditions. If charging were to take place constantly and only be switched off when the supply is interrupted, the working life of the product would be reduced dramatically. The maximum charge voltage should be set somewhere between 2% and 3% higher than the specified nominal voltage (rated voltage). This compensates for the voltage drops at the product’s internal resistor. Cell voltage is always lower than charge voltage. It is very important that the energy storage capacitors are loaded up to full nominal voltage. Higher voltages should not be used. It must be taken into account that the product of charge current*charge time is equal to the maximum charge. Only then is the maximum degree of effectiveness and the highest possible energy storage achieved.

ENYCAP 196 HVC series capacitors are specified for normal storage conditions of –40° to +85°C. However, after one year of storage, the parts should be powered and charged. Self-discharge is low. The permanent charge voltage of a fully charged capacitor must be limited to ≤20 µA; otherwise, the product will age early. If higher current flows, it must be ensured that the ENYCAP 196 HVC is removed from the circuit. Complete self-discharge must also be avoided. Most of the energy can be removed from the single cell between 1 V and 1.4 V. Cell voltages under 1 V result in deep discharge. As a result, low discharge currents can already have negative influence on the product’s properties.

When selecting the other components, great care was made to ensure low dc-circuit loss, low temperature factor, and high efficiency inductances to make the available energy as fully usable as possible. Also, input protection circuitry with TVS diodes was implemented to avoid overvoltage events of the complete circuit.

Advertisement

Learn more about Vishay Intertechnology