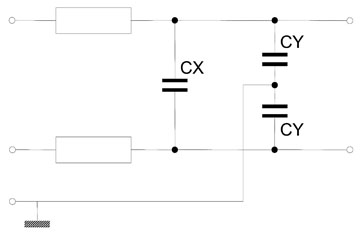

Devices that plug into an AC mains outlet need protection from EMI. A Pi filter, as shown in Figure 1, is often used for this application.

Figure 1: The Pi AC input filter

Safety standards exist to protect people and equipment should the components in this filter fail. Capacitor manufacturers offer devices for this application known as “X/Y caps”, “EMI filters” or “safety EMI capacitors.” These are capacitors that pass safety approvals for use in AC line EMI filters.

The safely standard

The IEC standard for EMI capacitors is 60384-14. You may also find references to UL 1414 (Across-the-line) and UL 1283 (EMI Filters). These standards subdivide EMI filter capacitors into two groups: X and Y.

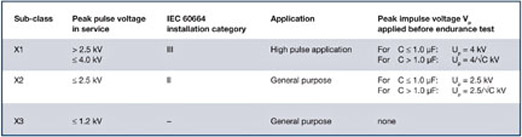

In most filter designs, you will find a single X capacitor. Depending on the voltages applied, the capacitor may be designated X1, X2, or X3 as shown in Table 1. Most applications will use an X2 capacitor.

Table 1: X Capacitor designations

Since X Capacitors are placed “across-the-line”, there is not a danger of exposing a person to electric shock if they fail. Obviously, however, they could cause a short circuit if shorted, so they must be designed to fail open.

For the Y capacitors: While a Pi filter is typically two capacitors and an inductor, one of the capacitors of that Pi filter will actually be two capacitors in series. Their common connection goes to ground. Visually this looks like the letter “Y”.

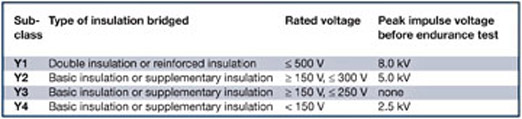

Like X capacitors, there are some designations for Y capacitors. Table 2 shows the key differences between Y1, Y2, Y3, and Y4.

Table 2: Y capacitor designations

Because Y capacitors are connected to ground, they are in a position where a failure of a capacitor could expose a person to a dangerous electric shock. For this reason, the designations define the type of construction used for the capacitor. In critical applications, an Y1 will provide the most protection in the event of a failure.

Why use film for safety capacitors: self-healing

One of the unique capabilities of metalized film dielectrics like polypropylene or impregnated paper is that they have the ability to “self-heal” the dielectric layer. This is why film capacitors fail open. If a conducting particle or a voltage surge punctures the dielectric, an arc occurs at the point of failure melting the surrounding metal and insulating the area from the breakdown.

The self-healing mechanism provides different results in the two different kinds of metalized dielectrics mentioned. In metalized plastic film dielectrics, like polypropylene, a breakdown causes a reduction of the insulation resistance (IR) due to a higher carbon deposited in the breakdown channel than for paper. Paper capacitors are commonly used for Y1 capacitors because a breakdown caused by a short transient normally results in improvement of the insulation resistance. Applications troubled with high transient voltages typically prefer metallized paper capacitors.

Test Voltages

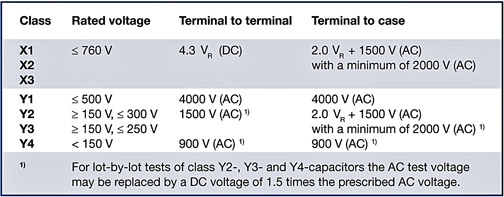

For qualification, safety capacitors are exposed to higher than rated voltages. Table 3 shows test voltages used for film capacitors from one manufacturer; always some multiplier higher than the rated voltage. VR =rated voltage.

Table 3: Test voltages

Repeated high voltage tests should be avoided as it is destructive regardless of type of dielectric or the manufacturer. This point is also made in most EMI suppression standards.

In general, DC test voltages are preferable to AC. The ionization caused by AC voltage increases the risk of permanent damage to the capacitor. Most manufacturers will perform a high voltage test on each capacitor at the time of production, using a voltage specified in the appropriate datasheet. Typically, the end-customer should be able to use the same test voltage, provided it is applied for only 1 or 2 seconds.

An example of EMI suppression capacitors using metalized film or paper would be the Kemet F861 (X2) or P295 (Y1). They provide agency approved options for EMI Filters. In addition to the appropriate approvals, these capacitors are designed to fail safely should a fault occur.

Advertisement

Learn more about Kemet Electronics