BY DAVID FAUSZ

Engineer, Communication Products

General Cable

www.generalcable.com

With the IEEE 802.11ac next-generation wireless standard that promises to deliver 1.3 Gbits/s expected to be ratified in early 2014, many might think that the wired versus wireless debate is over. While gigabit Wi-Fi will certainly solidify wireless as the de facto choice in the home and support more standard business applications in the enterprise space, there are still several factors to consider when deciding whether to deploy wireless or wired solutions — especially in industrial environments.

Inherent concerns remain

With the explosion of mobile devices and bring-your-own-device (BYOD) policies, virtually all commercial businesses today have wireless. There is no doubt that wireless access is an absolute necessity in the workplace today, enabling the freedom for employees to move around the office and visitors to remain connected.

While companies welcome increasing Wi-Fi speeds and the upcoming 802.11ac capacity that will reduce the current strain on wireless networks, wireless is still a long way off from becoming the norm. Few commercial environments rely solely on wireless, and those that do are typically small businesses with a handful of users and simple, low-bandwidth applications. With plenty of legacy wired infrastructure in place that can support gigabit speeds and power over Ethernet (PoE) to a wide variety of end devices such as phones, video surveillance cameras and access control devices, wireless will coincide with wired networks for several decades. Furthermore, wireless continues to cause plenty of headaches for IT staff.

Security concerns have plagued wireless from day one. Although authentication, encryption and intrusion detection technologies have drastically improved to the point where wireless is almost as secure as wired, most businesses are still reluctant to allow critical corporate data to transmit across the wireless network.

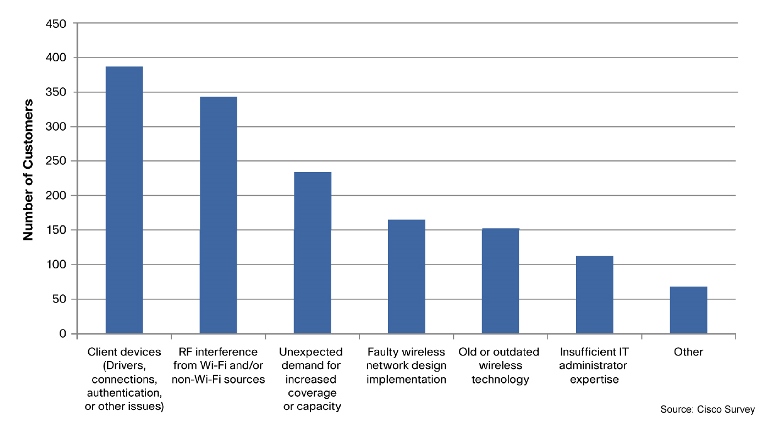

Another real concern surrounding wireless is performance. Wired connections support transmission rates that are at least 10 times faster than wireless (that is, 10 Gbits/s vs. 1 Gbit/s), and wireless is much more unpredictable when it comes to reliability. Regardless of technology advances, wireless remains a shared medium with inherent bandwidth limitations, potential for interference, and a variety of other performance-impacting contributors (see Fig. 1 ).

Fig. 1: Contributors to wireless network performance problems. Data based on Cisco survey where respondents had the option of selecting any or all of the issues listed. For the “Other” category, respondents listed issues such as lack of funding, lack of personnel, poor security implementation, application related errors and electromagnetic interference in manufacturing and transportation environments.

Because wireless is a shared medium, transmission speed depends on the number of users. The performance can also be impacted by the technology of those users. For example, the gigabit wireless speeds promised by the upcoming 802.11ac standard will depend on the number of users as well as the presence of other slower-speed 802.11a and 802.11n users on the system. While compatible with 802.11a and 802.11n, 802.11ac operates on a wider 80-MHz channel while 802.11a transmits on 20-MHz channels and 802.11n on 20- or 40-MHz channels. Therefore, in the presence of legacy 802.11a or 802.11n users, 802.11ac must fall back to accommodate their slower speeds, slowing down performance and reducing bandwidth for all users.

While some newer wireless access points (WAPs) offer greater ranges than early generation offerings, wireless will always have some limitations in how far a signal can travel and how much it fades the further away a device is from the access point. Multiple wireless access points must therefore be strategically deployed to ensure full, reliable coverage, which adds to the cost of implementing a wireless system.

Even when strategically placed, roaming occurs when a device moves outside the range of one WAP and into another. During the handoff process of a device disconnecting from one WAP to re-associate with another, there is a slight delay as the device scans for the new WAP. The device then needs to send an authentication request to the new WAP and wait for a response. Anytime there is a handoff process, there is a risk for dropped data packets and delays. Newer controllers on the market have succeeded in significantly improving the speed of the handoff process, but these solutions carry a high price tag and a more complex installation and configuration.

While newer wireless solutions have better penetration through office cubicles and walls than they did in the past, interference remains a concern. In a Cisco survey of more than 600 mid-market and enterprise customers, 78% considered their wireless network to be mission critical, but 54% indicated that radio frequency (RF) interference is still an issue. RF signals still tend to bounce off very large objects, metals or concrete, while other RF devices can interfere with the wireless system when frequency spectrums overlap. Noise emitted by large motors and heavy equipment can also interfere with the wireless system and potentially cause dropped data packets. As indicated in Fig. 2 , a network with 300 WAPs will experience an average of 15 RF interference events per month, affecting an estimated 180 users. As the number of WAPs increases, so does the number of events and affected users.

Fig. 2: Projected RF interference events per month and number of users affected by RF interference events

Limitations for the factory

While the reliability and performance of Ethernet has increased its popularity as a standard protocol for industrial applications, replacing many traditional fieldbus protocols, that does not exactly mean that wireless is also cut out for all industrial environments.

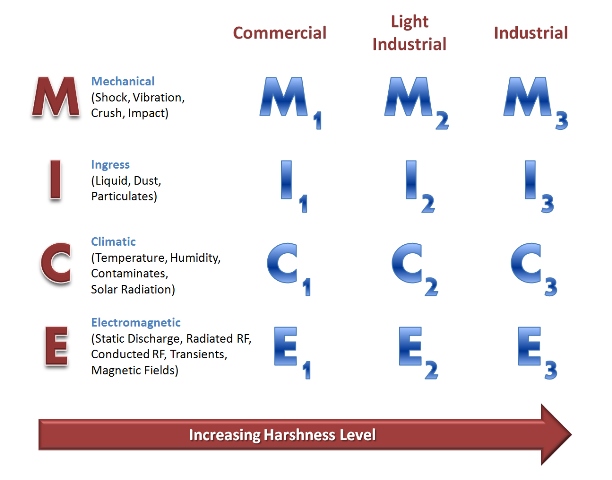

Industrial facilities like factories and food processing plants have many harsh environments with several factors that are different from commercial spaces. In these spaces, the MICE method is used to classify various areas and define the requirements for materials needed to build an industrial communications networks. MICE stands for mechanical, ingress, climatic/chemicals and electromagnetic, and there are three classifications used to define the categories based on the harshness of the environment—Level 1 for office, Level 2 for light industrial and Level 3 for industrial (see Fig. 3 ). In environments that have a high electromagnetic level (that is, E3), wireless communications is highly susceptible to the increased interference.

Fig. 3: The MICE method is used to classify industrial environments based on key parameters.

Many systems in an industrial environment also need to transmit data or I/O signals in real time, and latency cannot be tolerated. While a dropped data packet due to interference, roaming or multiple users on a wireless network typically goes unnoticed when simply sending an inter-office email, it can potentially cause industrial equipment to stop working. Many types of industrial equipment such as robotic arms are designed to be fail-safe and shut down when there is a delay or interruption in time-critical commands to prevent a safety hazard or production errors. This can result in costly production delays. Furthermore, as data transmission speeds increase, networks are increasingly susceptible to packet loss and failures. For example, as wireless networks move from 100 Mbytes/s to 1,000 Mbits/s (that is, 1 Gbit/s), an interruption in communications can now wipe out 10 times as much data. Therefore, at higher network speeds, resistance to interference and other factors that can cause latency and dropped data packets is more important than ever.

As Ethernet continues to take off in the industrial environment, another limiting factor of wireless communications is its inability to support PoE. The use of PoE already exists in the industrial environment to power security cameras, phones, clocks, time and attendance systems, building automation devices and shipping information systems. Several industrial Ethernet switches also now enable PoE, and it is anticipated that the technology will continue to appear in other industrial devices such as sensors, detectors and human machine interfaces (HMIs). With several industrial devices still requiring specialized cables, harnesses and protocols, and many device manufacturers are just starting to implement Ethernet; the next logical step is to deploy PoE wherever possible. Not only does the cost for equipment manufacturers to implement wireless communications into most industrial devices add little value, but wireless would also eliminate the ability to eventually deploy PoE.

However, there are some systems in the industrial environment that can benefit from wireless communications and mobility. For example, radio frequency identification (RFID) systems used to track products in a warehouse or packaging area can interface wirelessly with handheld scanning devices. Wireless can also be used for other non-critical industrial applications like data collection with simple data exchange that does not impact operations.

As interference immunity, latency, throughput capacity and range improves, additional non-critical industrial systems and sensors may be able to move to wireless I/O control, if they don’t want to take advantage of PoE. However, there is no substitute for wires when it comes to critical industrial systems that require reliable real-time control.

As we look toward the future, a combination of wired and wireless in both commercial and industrial environments will continue to be the norm — wireless will satisfy the needs of mobile workers and noncritical mobile applications, while wired will continue to enable PoE and ensure the security, capacity, performance and reliability requirements that many applications and environments demand.

Advertisement

Learn more about General Cable