BY DARIN GLENN,

Senior Engineering Manager, Vishay Intertechnology

www.vishay.com

The heat is on for the passive electronic component industry as it is seeing an increase in new surface-mount high-power devices, especially resistors. This is exciting because it creates opportunities to reduce the overall size of electronics. Unfortunately, we must still abide by the laws of physics. Resistors generate heat as a result of the properties that they create. When more power is applied to a resistor, more heat is generated. If this heat is not properly transferred from the part, the part may shift in value and, eventually, will fail.

There are new technologies using aluminum nitride (AlN) ceramics in place of aluminum oxide that boast extreme power ratings; for example, >100 W for a 1206 case size. The AlN ceramics have a much better thermal conductivity than that of aluminum oxide, approaching that of beryllium oxide. At first glance, this is very exciting and impressive until one considers how they are going to transfer the massive amount of heat away from the device and the rest of their circuit. Applying 100 W to a 1206-sized resistor will heat up the resistor rapidly to temperatures in excess of 500°C, which will melt solder joints and potentially damage most electrical components, especially active devices, if not properly dissipated.

Why do these resistors have these ratings? The devices themselves are capable of running at these power ratings due to the higher thermal conductivity of the substrate and the ability to transfer the heat away from the device. The challenge is where that heat gets transferred. Manufacturers include footnotes in the datasheets indicating active thermal management, elaborate heat sinks, or simply that the user must maintain the device at a given temperature — for example, 155°C.

Is it easy or cost-effective to implement the necessary thermal management for these high-powered resistors? No. This article is not intended to overwhelm the reader with thermodynamics and complex equations. The intent is to discuss a few techniques to manage the heat that is generated by high-power surface-mount resistors and the effects they will have on design space, complexity, and cost.

Background

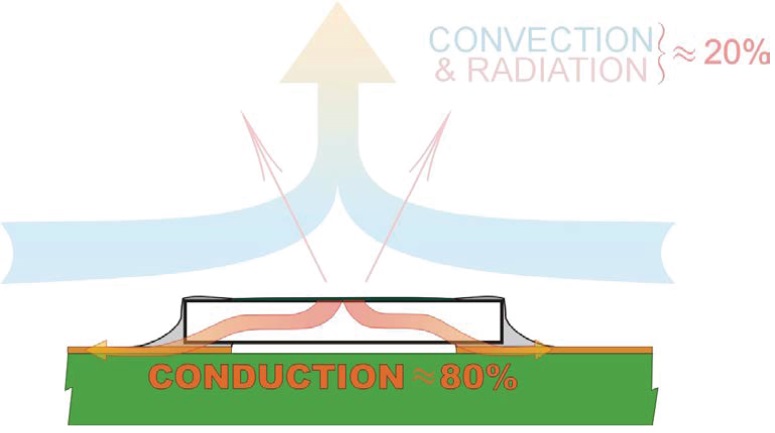

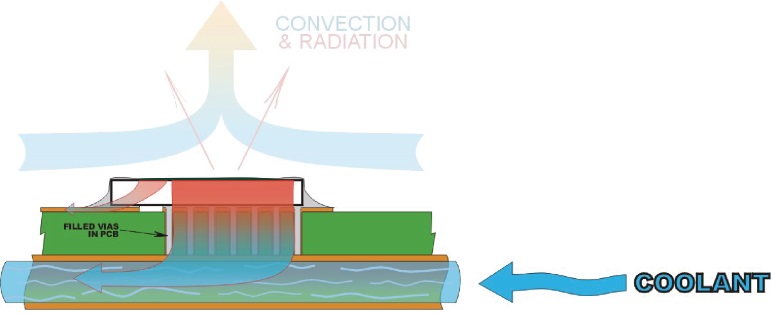

There are two main types of heat transfer with high-power surface-mount resistors: 1) conduction through the substrate and conductors to the board and traces (see Fig. 1 ), and 2) convection to the surrounding environment.

Fig. 1. Predominant types of heat transfer for high-power surface-mount resistors.

Conduction is the predominant means of heat transfer and, thus, many manufacturers will provide a thermal resistance for their device. Thermal resistance gives a first-order approximation of how well the device transfers heat to the board and traces as power is applied — that is, °C/W. This rating lacks many details. The main issue is the properties of the test card used to establish the rating. For example, the amount of copper employed on the test card will significantly affect the resulting thermal resistance of the device. Some manufacturers provide the details about how their devices were tested to establish the power rating or the thermal resistance. In many cases, the techniques employed are not practical in application.

Convection is an important factor to consider, especially if a board is enclosed. The heat that is radiated can quickly increase the ambient temperature to unsafe and damaging levels. If a board is encapsulated, it can be detrimental to the high-power component and surrounding components as it prevents transfer of heat by means of convection. It is highly recommended that high-power resistors not be encapsulated.

Some manufacturers’ power ratings assume an infinite heat sink. An infinite heat sink is one that can carry an infinite amount of heat away from the device. This is not realistic and, thus, may limit the amount of power that can be applied to a component.

Thermal management techniques

Heavy board traces:

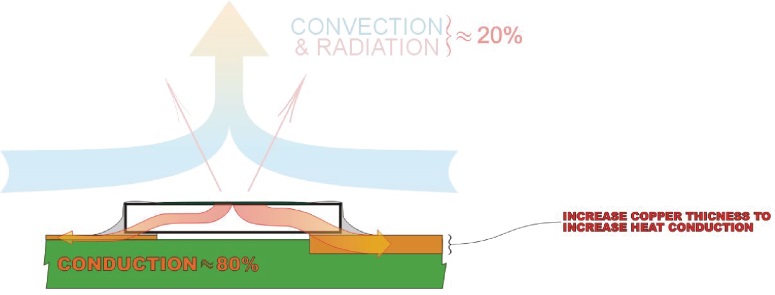

A simple and common technique is the use of heavy board traces. Adding surface area and volume to board traces is an easy technique to employ. Since most of the heat transfer from these devices is through conduction, this is a common technique. An example is shown in Fig. 2 . There are two options in employing this technique: 1) increase the width of the traces, and 2) increase the thickness of the traces.

Fig. 2: Example of implementing heavy board traces.

This technique spreads the heat generated by the resistor to the entire board, which increases the area over which the heat is radiated to the surrounding environment. The challenge occurs when steady state is reached. If active thermal management techniques are not included in the design, then the board and the surrounding environment eventually reach a peak temperature that may exceed safe operating temperatures.

This technique is typically lower in cost. There are still higher costs due to the amount of metal used for the traces (typically copper). In addition, there is added weight and increased board size to accommodate the heavy board traces.

Thermal back plane:

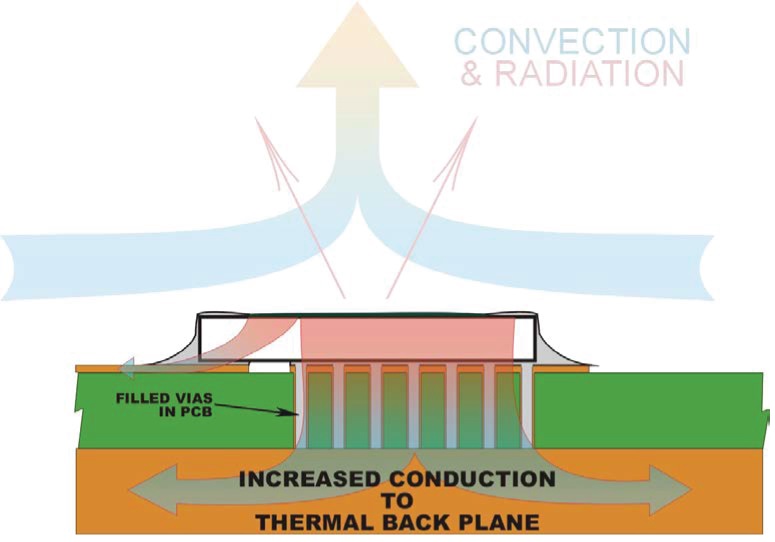

A similar, more robust technique is to employ a thermal backplane. This technique uses a larger copper plate on the back side of the board to transfer the heat away from the circuit. As with the heavy board trace technique, the heat is spread over a large thermal mass, which will increase the area to transfer heat by convection and radiation. An example is shown in Fig. 3 . Also, if active thermal management is not employed, the board and surrounding environment may exceed safe operating temperatures.

Fig. 3: Example of implementing a thermal backplane.

This technique adds higher cost as the backplane is typically made of heavy copper. In addition, this technique will add weight to the design and most likely restrict the board to a single layer, adding board size.

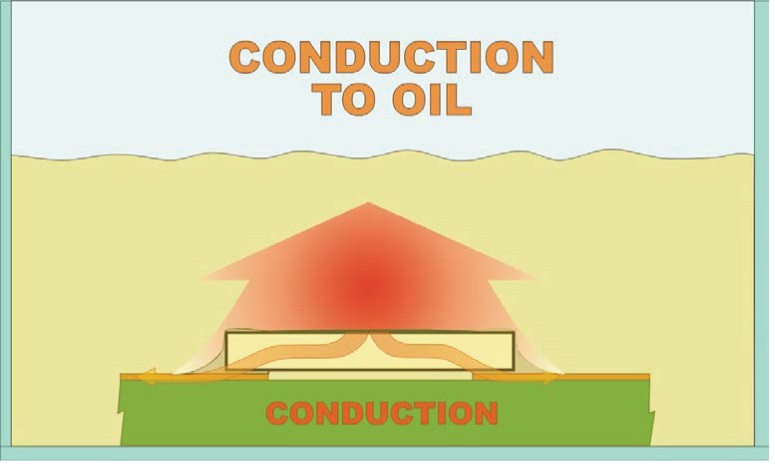

Oil submersion:

Submersing a board into oil is an effective method to carry heat away from the board and attached components. Since the oil is in direct contact with every surface of the board, the conduction of heat is very efficient. An example is shown in Fig. 4 . A couple of challenges with this technique are oil contamination and material compatibility. The oil must have very good dielectric properties. If the oil becomes contaminated, the dielectric properties may be decreased and lead to arcing and, thus, failure of the device or the board. The oils used can be very custom and may not be compatible with the materials of the high-power resistor, other components, or even the solder.

Fig. 4: Example of implementing oil submersion.

This technique, again, is limited at steady state if active thermal management is not employed. The fixed volume of oil will eventually reach a peak temperature that may exceed safe operating conditions.

This technique adds significant costs as the oils are typically a higher cost, and there must be some type of vessel to contain the oil. In addition, in many cases, gold contacts/terminations are employed to avoid reaction with the oil, adding very high costs.

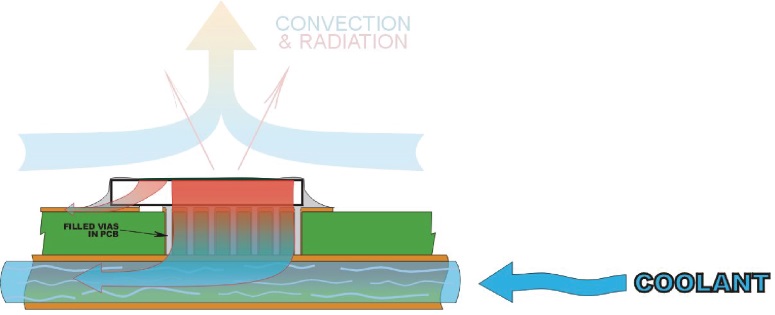

Active cooling:

Actively cooling a board can be very effective but at a much higher cost, typically over $10,000 when a compressor is used. One common technique is to employ a chiller, which circulates coolant. This can be used with a thermal backplane, wherein the coolant circulates through channels in the plane or tubing that is thermally connected to the surface of the plane. An example is shown in Fig. 5 . This method can also be used with the oil bath, wherein the oil is circulated continuously through the chiller. Both of these techniques “pump” heat away from the thermal backplane or the oil bath.

Fig. 5: Example of implementing circulated coolant though a thermal backplane.

Another technique is to employ forced air, whether conditioned or unconditioned. Applying forced air to a board is relatively easy and can be achieved at a reasonable cost. The effectiveness of this technique is limited as it relies on convection and the surface area of the high-power resistor. An example is shown in Fig. 6 . There are high-power resistors that are encased in heat sinks, which aid in the cooling process by significantly increasing the thermal mass and surface area. To employ this technique requires adequate free space surrounding the board to properly circulate the air. The air typically must be filtered to prevent contaminants from degrading the performance of the electronics.

Fig. 6: Example of implementing forced air cooling.

High-power surface-mount resistors offer increased power capabilities, even with standard board-mounting techniques, due to the reduced thermal resistance of the substrates (for example, AlN), typically two to three times that of standard chip resistors. In order to achieve higher power, more elaborate techniques must be employed, as discussed in this article. Designers must be very careful when selecting high-power surface-mount resistors. Simply because a data sheet claims extremely high powers, the burden is on the designer to maintain certain criteria — for example, maximum surface or terminal temperatures that are typically noted in the fine print.

Advertisement

Learn more about Vishay Intertechnology