Imagine what happens when a manufacturer producing 50-50 red and green items learns that 56 percent of its customers prefer green items and only 44 percent prefer red. What usually happens next? Well, traditionally, a week or more is spent changing 50-50 production runs.

But what if we can respond more quickly to market conditions and change it right away? That’s exactly how networked automation has revolutionized manufacturing, with its not-so-secret weapon: Industrial Ethernet. The technology offers deterministic delivery, time-triggered support, greater distances and safer, more reliable operation compared to the advantages of traditional Ethernet. Through this innovation, industrial customers can expect the advantages of speed, safety, efficiency and flexibility brought by advanced network communications between the front office and the field, brining data in real time.

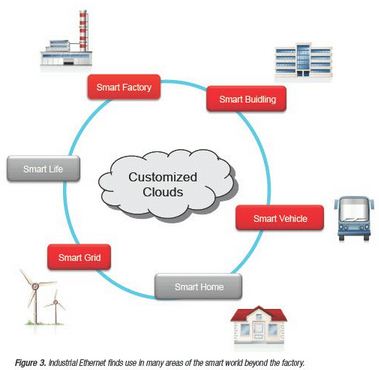

This “Smart Factory” concept is revolutionary. In Germany, they have dubbed this new era of manufacturing as “Industry 4.0” to emphasize the same importance this revolution holds, right alongside industrial revolutions of steam power, mass production and early automation.

Manufacturers have been introducing these systems for decades, but centralizing control was an impediment for the proprietary and, quite often, incompatible networks that weren’t interconnected. This is where Ethernet comes to play. It is the best choice for data networks and makes sense for industrial communication as well, in addition to being widely understood and supported. One caveat is Industrial

Ethernet requires modification in order to meet its application requirements.

IC solutions and the supporting software must provide a basic technology that is common to existing protocols, allowing equipment manufacturers to build the devices into systems that uses their own intellectual property. Moreover, multiple protocols may be used in a single factory, especially where older serial communications continue to exist alongside more recently deployed Industrial Ethernet.

Therefore, IC solutions must have the capability for multi-protocol support in a single device, providing the means to communicate with legacy equipments and keep them functioning in a more up-to-date control environment. When these features are available in an inexpensive solution, equipment manufacturers can easily build flexible, advanced Industrial Ethernet into their products.

TI technology is significantly adding to the momentum. Advanced sensors may be designed into these equipments to provide sophisticated environmental interaction, as well as communication with TI-enabled wireless sensing nodes to extend functionality over wide areas.

Smart factories are only the beginning of the list of potential applications for Industrial Ethernet based on TI semiconductor advancements. Other areas such as transportation, automotive systems, power distribution and building installations are also benefiting from the same communications technology.

You can read more about it in our latest white paper here .

Buy the TMDXICE3359 ARM Ind Comm Engine now at Mouser Electronics

Advertisement

Learn more about Texas Instruments